Supporting plate and supporting assembly frame

A technology of support plate and frame, applied in the field of sofa connection and fixation, can solve the problems of easy hand injury, easy wear of sofa fabric, difficult disassembly of the support plate, etc., and achieves the effect of reducing the difficulty of disassembly, easy operation, and simple and convenient peeling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

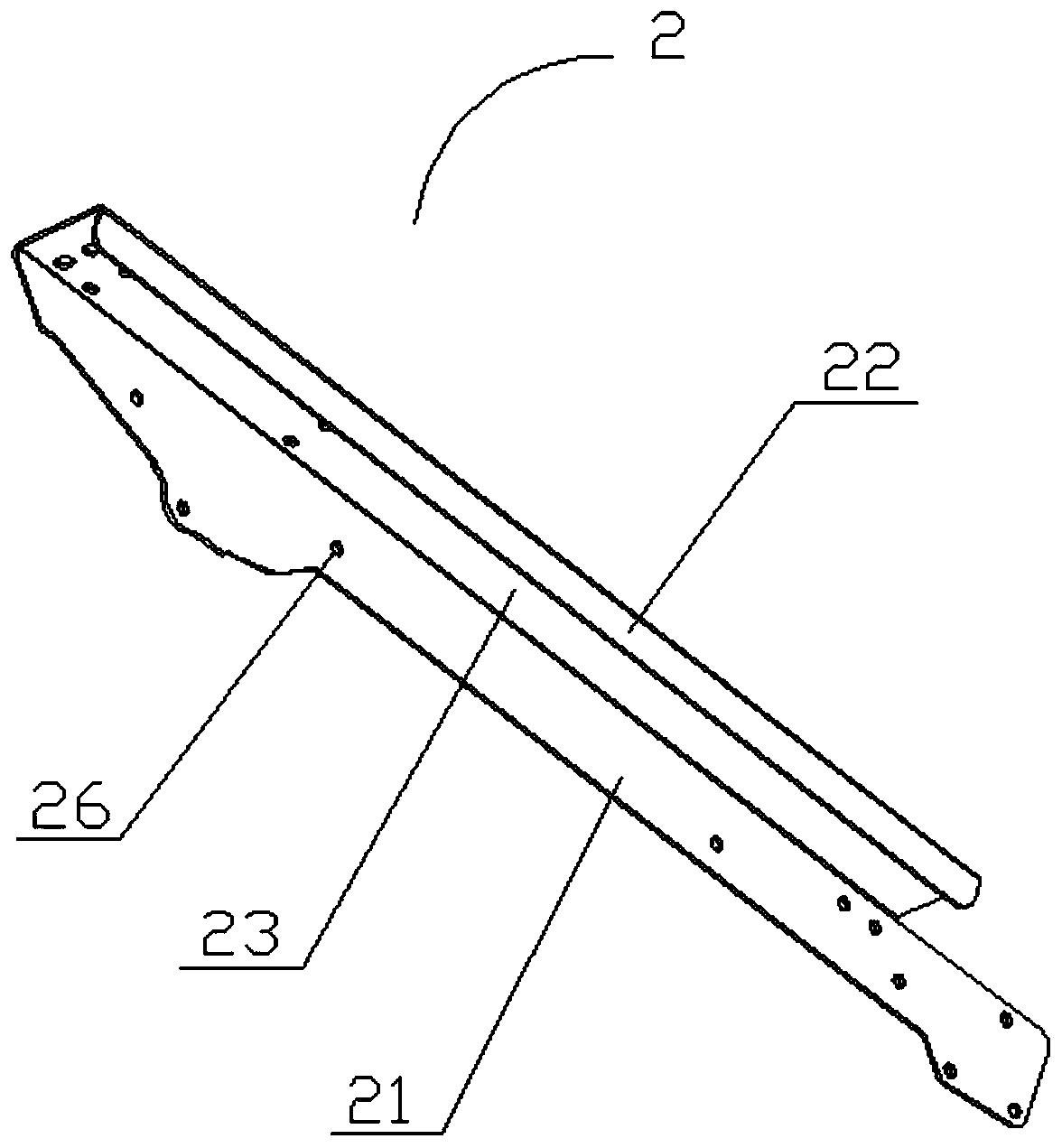

[0045] refer to Figure 1 to Figure 3 , the present invention provides a support plate 2, which is applied to the iron frame of the functional sofa. The connectors of the sofa are snapped together to complete the leather touch process of the sofa fabric and realize the assembly of the soft bag.

[0046] In this embodiment, the support plate 2 includes an inner plate 21, an outer plate 22 and a panel 23, wherein the inner plate 21 and the outer plate 22 are both arranged on the lower surface of the panel 23, and the outer plate 22 is arranged opposite to the inner side plate 21 .

[0047] In this embodiment, the inner side panel 21 can be used to be hinged with the driving link group 3 of the functional sofa iron frame. Specifically, the inner side panel 21 is provided with several driving links for hinged functional sofa iron frame Hinge point 26 for group 3. In another preferred embodiment, the inner panel 21 can also be used to be hinged with the backrest assembly 9 and t...

Embodiment 2

[0064] refer to Figure 4 , the structural difference between the support plate 2 of the present embodiment and embodiment 1 is that the support plate 2 does not include the outer plate 22, which is now specifically described as follows:

[0065] The supporting plate 2 of the present embodiment includes a panel 23 for supporting the soft bag and an inner panel 21 vertically fixing the lower surface of the panel 23, and the inner panel 21 is provided with a plurality of connectors for clamping on the sofa fabric. The buckle hole 24, the inner side plate 21 and the buckle hole 24 constitute the fitting part of this embodiment, and are used to cooperate with the connecting parts on the sofa fabric to realize the installation of the soft bag. In the actual manufacturing process, the buckle holes 24 are square holes, and a plurality of square holes are equally spaced on the inner panel 21 .

[0066] Specifically, the inner panel 21 and the panel 23 roughly form an inverted L shape...

Embodiment 3

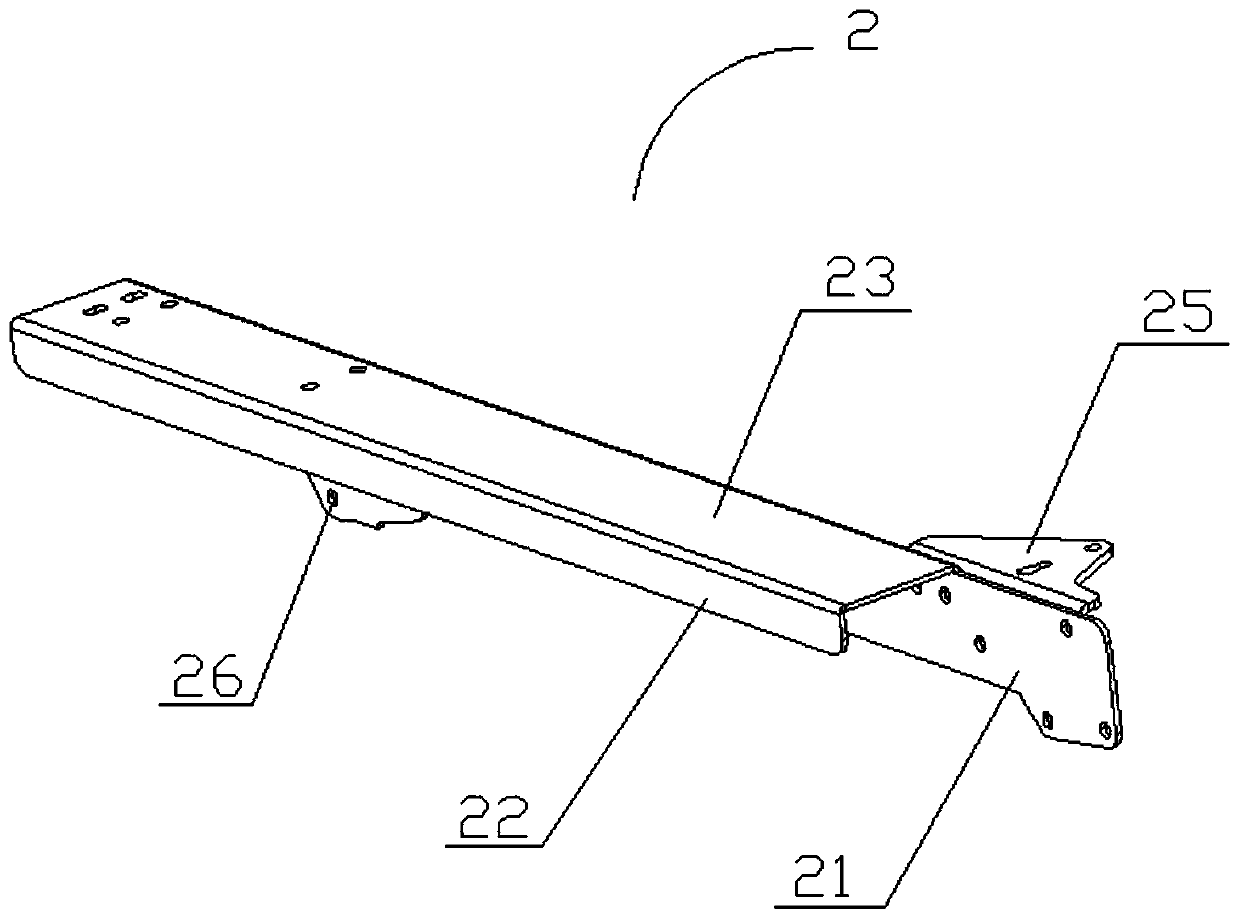

[0074] refer to Figure 5 with Image 6 , this embodiment provides a support assembly frame, which is applied to a functional sofa iron frame, and the support assembly frame includes two opposite support plates 2, a front bar 4 and a rear bar 5 as described in embodiment 1 or embodiment 2 The front rod 4 and the rear rod 5 are arranged between the two support plates 2 correspondingly at intervals.

[0075] Preferably, in this embodiment, both the front rod 4 and the rear rod 5 are made of metal. Indeed, in another preferred embodiment, the front rod 4 and the rear rod 5 can also be made of engineering plastics by injection molding, or made of a combination of metal and engineering plastics.

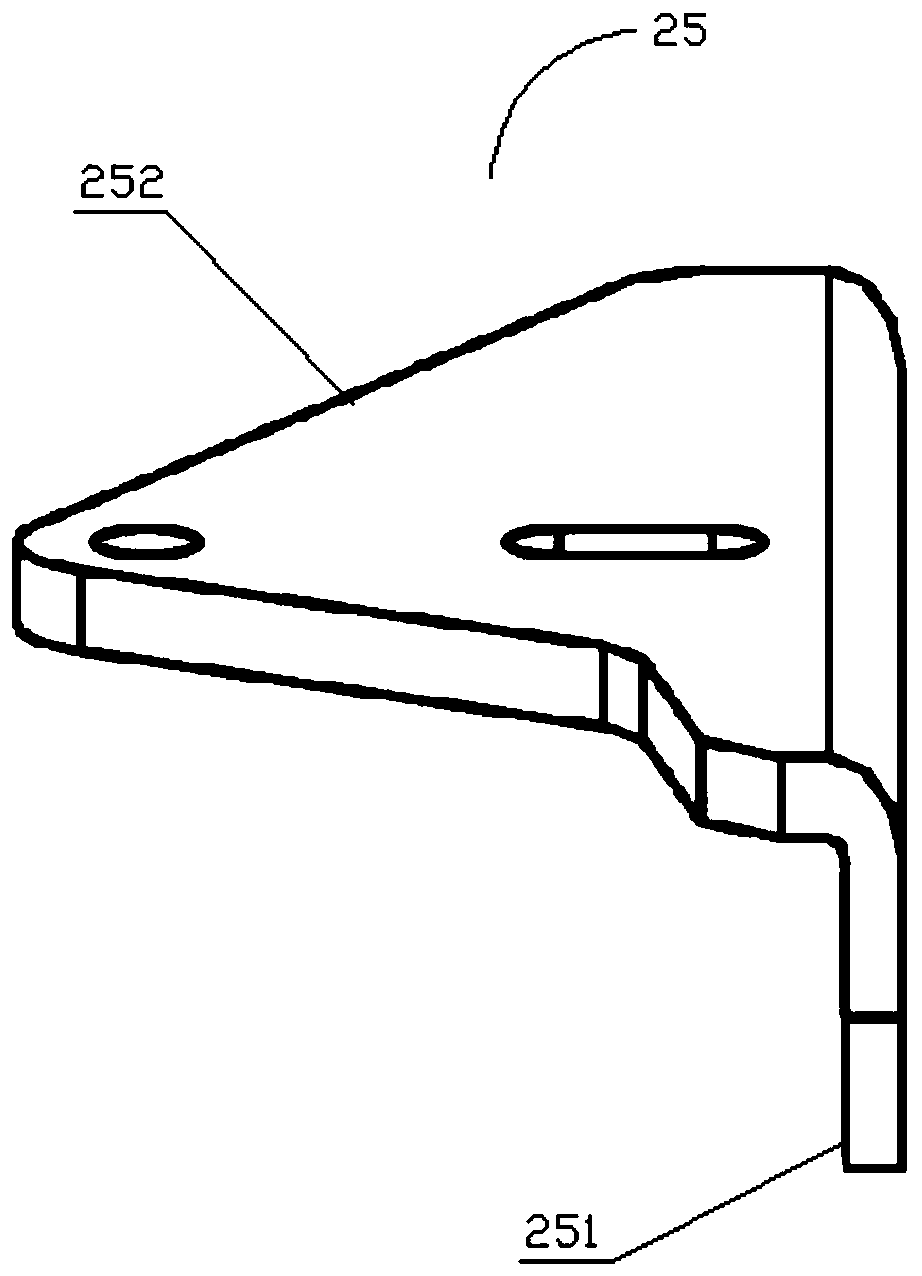

[0076] In this embodiment, both ends of the front rod 4 are respectively connected to the two support plates 2 through bolts, and the rear rod 5 is connected to the L-shaped bearing member 25 .

[0077] In this embodiment, through the hinged cooperation relationship between the hinge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com