Intelligent garment of integrated spinning base temperature sensing network

A sensor network and smart clothing technology, applied in clothing, sensors, clothing, etc., can solve problems such as difficult to guarantee product reliability, cannot be washed, and smart clothing materials are easily interfered by external factors, so as to ensure wearability and guarantee The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

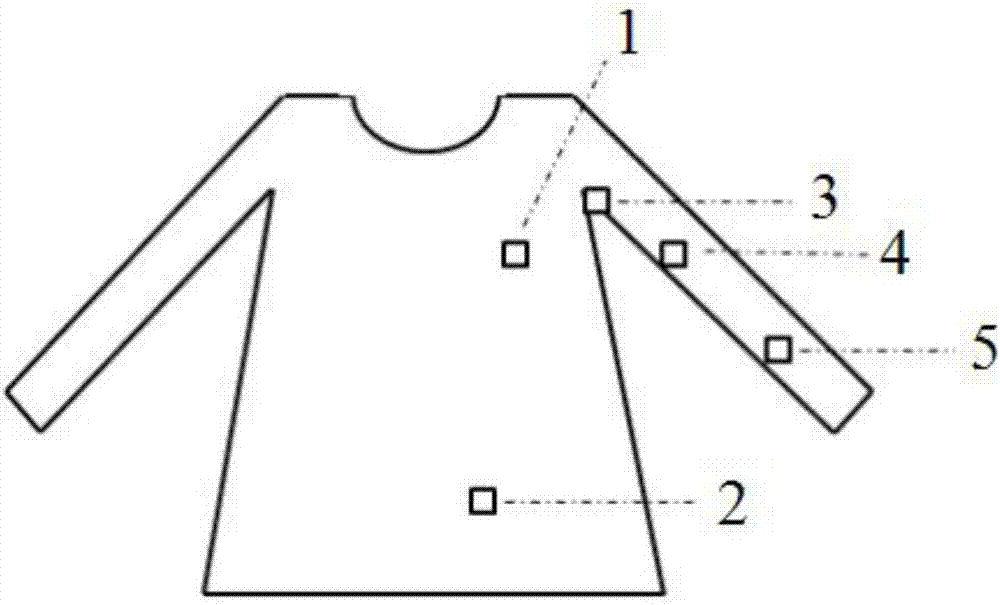

[0026] Embodiment 1: Weaving of temperature sensor of woven structure

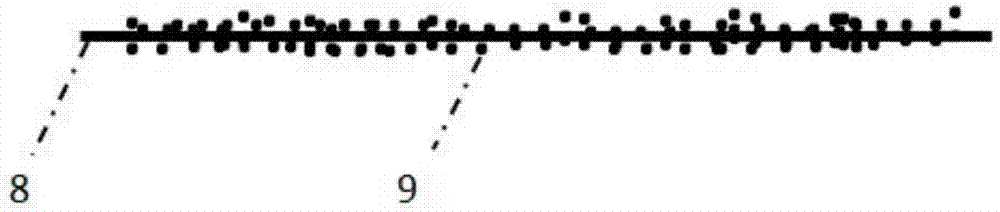

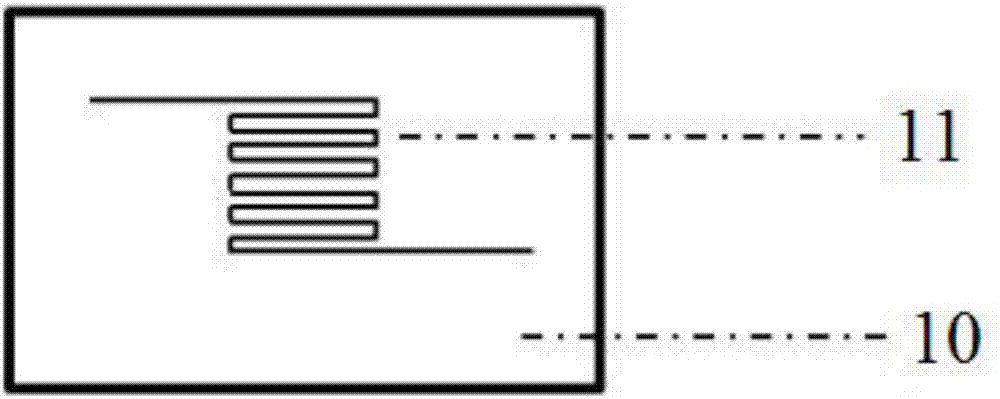

[0027] The woven fabric is used as the base, and the specifications of the woven fabric are as follows: ↗twill weave, straight wear; reed number: 46, 2 reeds per reed; the base warp and weft yarns are made of cotton yarn, and the size of the sensing unit is 1cm x 1cm, with Cotton yarn is used as warp yarn, and metal platinum Pt fiber is used as weft yarn for weaving. For the convenience of post-production, 1cm of Pt fiber is left on the left and right sides of the sensor (see image 3 ).

[0028] Sensor preparation

[0029] At the two Pt fiber head ends a.c left on the left and right sides of the sensor (see Figure 4 ) each connect a silver wire of a certain length, tie a knot at the a.c connection and drop a few drops of conductive silver paste, bake in a 600C oven for 30 minutes, take it out after drying and cool to room temperature; cut two round TPUs with a diameter of 5mm Paper and woven fabric o...

Embodiment 2

[0036] The thermal resistance of nickel Ni fiber is very good; copper Cu fiber has good electrical conductivity. Therefore, Ni fibers can be used to weave the sensing part of the sensor, and Cu fibers can be used as wires to connect circuits. In the same way as above, the fiber ends left on the left and right sides of the sensor are connected to a certain length of Cu fiber and consolidated, and then each sensor is connected and fixed to the corresponding part of the clothing through the Cu fiber.

Embodiment 3

[0038] Fiber temperature sensors also have certain advantages, and the production of fiber sensors is done by coating with temperature-sensitive materials; therefore, temperature-sensitive materials can be coated on the surface of nylon fibers, such as nickel powder / graphite / silica gel composite materials, and then the fiber It can be woven into the corresponding position of the garment by means of padding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com