Device for performing flue gas mercury concentration measurement by utilizing modified fly ash

A mercury concentration and temperature control device technology, applied in the direction of measuring devices, sampling devices, test sample preparation, etc., can solve the problems of unfavorable promotion, inability to detect mercury concentration, and long measurement time, so as to reduce costs and improve adsorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] The invention provides a device for measuring flue gas mercury concentration using modified fly ash, which uses a cheap and efficient modified fly ash adsorbent as a substitute for activated carbon to measure flue gas mercury concentration, and uses an atmosphere control device to control the flue gas mercury concentration. The adsorption atmosphere improves the adsorption efficiency of cheap adsorbents, and ensures the accuracy of flue gas mercury concentration measurement while reducing costs.

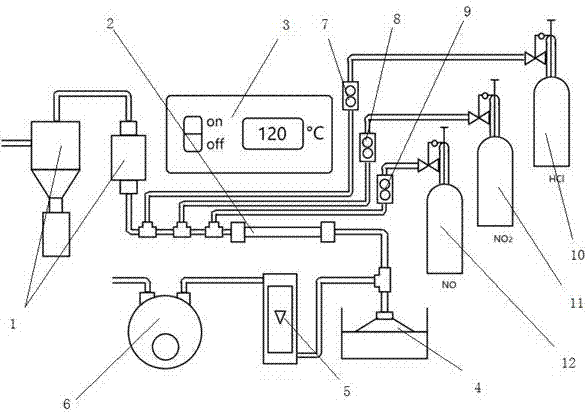

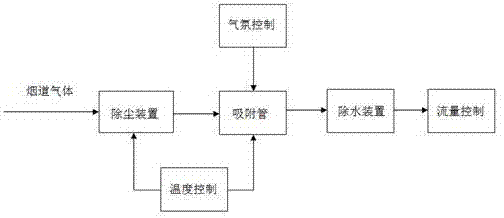

[0022] Such as physical connection diagram figure 1 and flow diagram figure 2 As shown, the flue gas sampled from the flue first flows through the dust removal device 1 to remove the fly ash in the flue gas; Adsorbent capture; then flow through the tail gas treatment device to remove harmful gases and moisture in the tail gas; finally reach t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com