Automatic oil spraying device for bolt holes of engine bodies

A technology of engine body and fuel injection device, which is applied in the direction of engine components, engine lubrication, mechanical equipment, etc. It can solve problems such as unguaranteed lubrication effect, inaccurate nozzle positioning, and poor lubrication effect, so as to improve atomization effect and lubricate The effect of good effect and good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

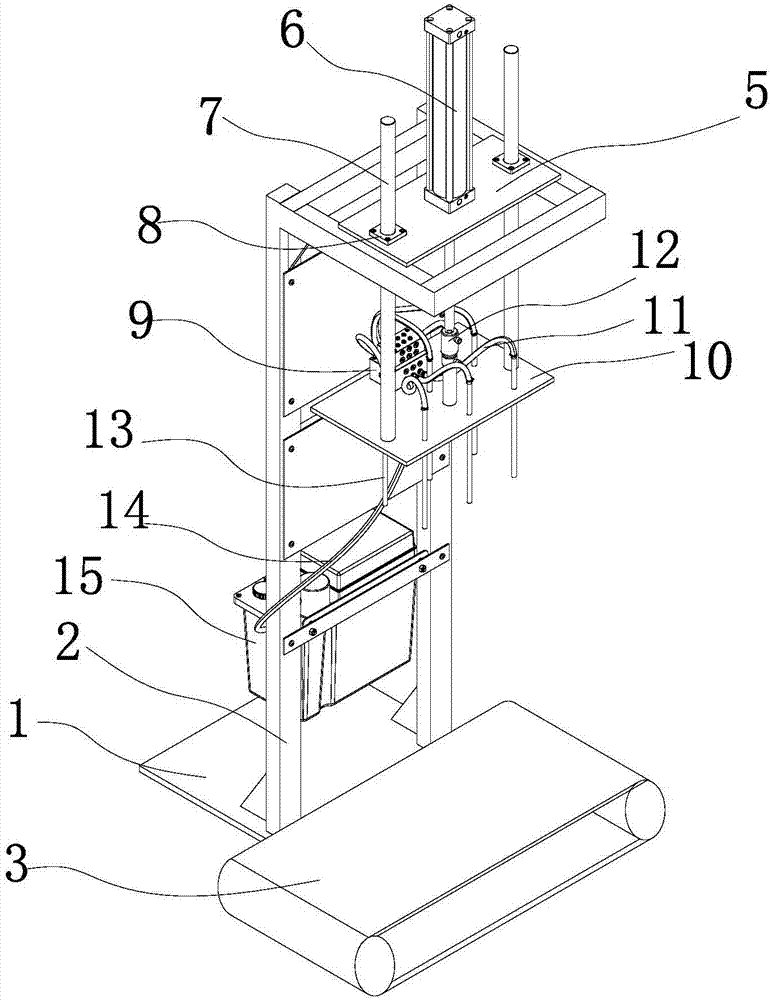

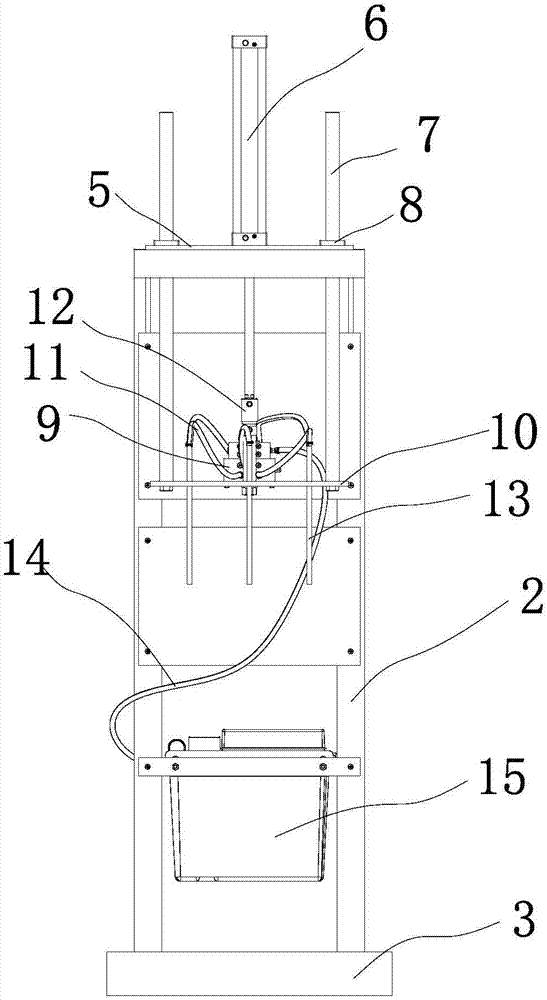

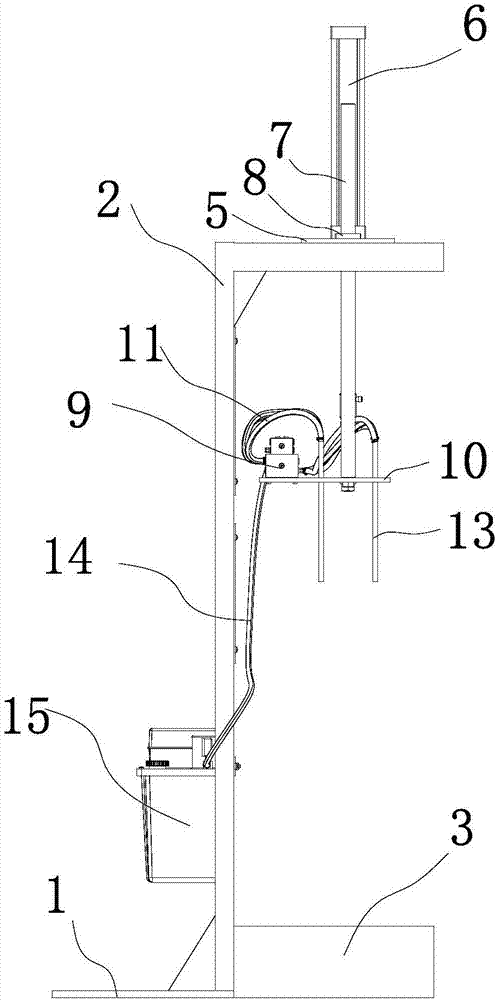

[0045] Such as Figure 1 to Figure 10 As shown, the engine body bolt hole automatic fuel injection device according to the present invention includes a frame 2, a fixed plate 5 is arranged on the frame 2, a driving device is arranged on the fixed plate 5, and the working end of the driving device passes through the fixed plate 5 and is connected. Skateboard 10, the slideboard 10 is provided with an oil-air mixer 9, the output end of the oil-air mixer 9 communicates with the nozzle 13 through the first hose 11, the nozzle 13 is installed through the skateboard 10, and the input end of the oil-air mixer 9 communicates with the lubrication through the second hose 14 pump 15.

[0046] The lubricating pump 15 can be fixed to the frame 2 , and the lubricating pump 15 can also be fixed to the slide plate 10 . The driving device can be an air cylinder 6 or an electric cylinder.

[0047] The bottom of the frame 2 can be provided with a base 1 to ensure that the automatic fuel injecti...

Embodiment 2

[0050] Such as Figure 1-Figure 4 As shown, the slide plate 10 is provided with a guide shaft 7 , and the guide shaft 7 is arranged through the fixed plate 5 . A linear bearing 8 may be provided at the joint between the guide shaft 7 and the fixed plate 5 . The friction between the guide shaft 7 and the fixed plate 5 is reduced, a good guiding effect of the guide shaft 7 is ensured, and the movement accuracy of the slide plate 10 is improved. The number of guide shafts 7 can be set according to needs, and the effect of setting 2, 3, and 4 guide shafts 7 is better, which can increase the accuracy of the guiding effect, and at the same time, will not increase the movement resistance. The guide shaft 7 can guide the movement of the slide plate 10 to ensure that the movement direction of the slide plate 10 is accurate and that the nozzle 13 can be accurately inserted into the bolt hole. All the other are the same as embodiment one.

Embodiment 3

[0052] Such as Figure 1-Figure 4 As shown, slide rails and slide blocks that cooperate with each other are provided between the slide plate 10 and the frame 2 . It can further enhance the moving accuracy of the sliding board 10 and reduce unstable factors such as vibration during the moving process of the sliding board 10 . All the other are with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com