Preparation method of a special-shaped cross-section monofilament exposed bottom transparent jacquard three-dimensional fabric

A special-shaped cross-section and fabric technology, applied in the field of knitted fabrics, can solve the problems of hard hand feeling, easy aging, poor color fastness, etc., and achieve the effects of small contact area, moisture absorption and quick drying styles, and different patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

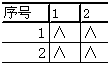

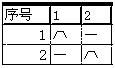

[0019] Example 1, such as Figures 1 to 3 As shown, a preparation method of a special-shaped section monofilament exposed bottom transparent jacquard three-dimensional fabric comprises the following steps. The surface circular weft jacquard machine is woven into a fabric gray cloth, the fabric gray cloth has a staple fiber yarn surface, and a number of cross-section polyester monofilaments are alternately woven up and down on the staple fiber yarn surface; the cross-section polyester monofilament The filaments are intermittently woven on the spun yarn surface, and the cross-section polyester monofilament is alternately woven up and down on the spun yarn surface. That is, 30S polyester-cotton blended CVS40 / 60 is woven into a staple fiber yarn surface, and cross-section polyester monofilaments are interwoven on the staple fiber yarn surface. It can also weave irregularly on the spun yarn surface. The spun yarn surface has a 2-way triangular structure, and the 1st and 2nd lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com