Hybrid strengthened aluminum matrix composite and preparation method thereof

A technology for strengthening aluminum-based and composite materials, which is applied in the field of casting metal-based composite materials and its preparation, can solve the problems of high strength and toughness of composite materials, uneven distribution of reinforced particles, etc., achieve high toughness, improve various properties, combine Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

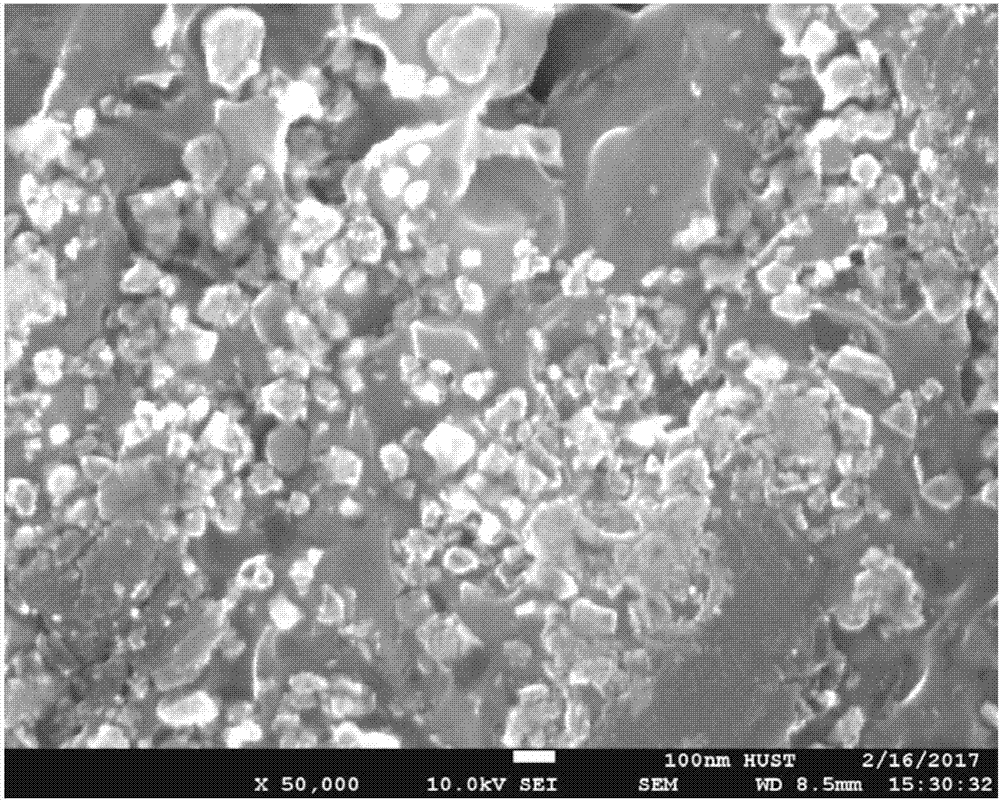

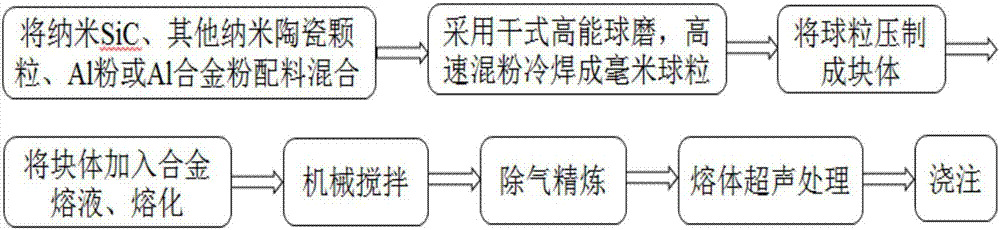

[0042] figure 2 It is a schematic flow chart of the preparation method of the present invention. It can be seen from the figure that a preparation method for preparing an aluminum-based composite material with added nanoparticles hybrid reinforcement mainly includes the following steps:

[0043] First, through dry high-energy ball milling, nano-sized SiC powder, other nanoparticles, and micron-sized aluminum or aluminum alloy powder are mixed to prepare millimeter-sized composite particles;

[0044] Then, using a mold and a pressure device, the millimeter-scale composite particles are pressed into a prefabricated intermediate alloy block; after the intermediate alloy block is added to the molten aluminum and melted, an ultrasonic-assisted stirring process is applied to prepare an aluminum-based composite material with excellent performance by adding nanoparticle hybrid reinforcement .

[0045] Concrete preparation process steps are as follows:

[0046] (1) Dosing and mixing...

Embodiment 1

[0057] The target components and weight percentages of the composite material in this embodiment are: SiC particles 1%, Al 2 o 3 Particles 1%, the balance is aluminum alloy ZL101 (that is, ZAlSi7Mg). Concrete preparation method is:

[0058] (1) SiC and Al with an average particle size of 20nm 2 o 3 Granules and pure aluminum powder with an average particle size of 20 μm are dosed in a mass ratio of 1:1:23.

[0059] (2) Through dry high-energy ball milling, SiC, Al 2 o 3 Millimeter-sized composite particles with a particle content of 4% by weight, respectively. The formed millimeter-scale composite particles have a particle size of 1 mm.

[0060] (3) Using a mold and a pressure device, the millimeter-scale composite particles are pressed into a prefabricated intermediate alloy block with a diameter of 80 mm and a height of 50 mm, the pressing pressure is 30 MPa, and the theoretical density of the alloy block is greater than 85%.

[0061] (4) Add pure aluminum or aluminu...

Embodiment 2

[0068] The target components and weight percentages of the composite material in this embodiment are: SiC particles 2%, Al 2 o 3 Particles 2%, the balance is aluminum alloy ZL201 (ZAl5CuMn).

[0069] (1) Mix SiC and Al2O3 particles with an average particle size of 40nm and pure aluminum powder with an average particle size of 40μm in a ratio of 1:1:14.7.

[0070] (2) Through dry high-energy ball milling, SiC, Al 2 o 3 Millimeter-sized composite particles with a particle content of 6% by weight, respectively. The diameter of the formed millimeter-scale composite particles is 2mm.

[0071] (3) Using a mold and a pressure device to press millimeter-sized composite particles into a prefabricated intermediate alloy block. Specifically, the millimeter-sized composite particles are pressed into a prefabricated intermediate alloy block with a diameter of 40 mm and a height of 30 mm, the pressing pressure is 10 MPa, and the theoretical density of the alloy block is greater than 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com