A kind of preparation method of aqueous phase suspension method cpvc resin

A technology of CPVC resin and PVC resin, which is applied in the field of preparation of CPVC resin by aqueous phase suspension method, can solve the problems of weakening the absorption capacity of CPVC resin additives, poor plasticization uniformity of CPVC resin, insufficient physical and mechanical properties, etc., and achieve good processing performance , good stability and easy plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

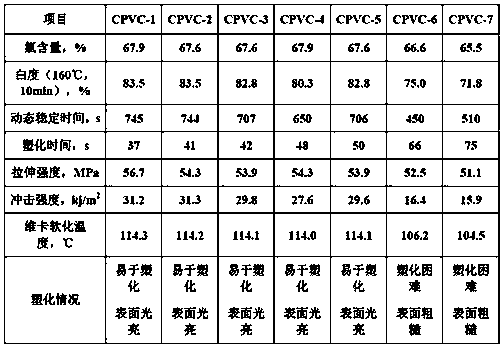

Examples

Embodiment 1

[0025] Add 80kg of deionized water into a 100L chlorination reaction kettle, and evenly spray 167g of glycerol aqueous solution with a mass ratio of 30% on the surface of 10kg of chlorinable PVC special resin QS-C65, and then add it to the chlorination reaction kettle , start the stirring device, PVC resin is quickly and evenly suspended in the water phase, add 125g of peroxydicarbonate with a concentration of 40%, use chlorine gas to discharge the air in the kettle, heat up the reaction kettle, slowly feed chlorine gas, and the temperature of the reaction kettle reaches 85°C When it is around, the chlorination reaction accelerates. Control the temperature of the reactor at 95°C, the rate of chlorine flow at 50g / min, and the pressure of the reactor at 0.2-0.4MPa. When the amount of chlorine flow reaches 6.8kg, stop the flow of chlorine and add a terminator with a concentration of 20%. 200g of diethylhydroxylamine, after 10 minutes, vacuumize to remove residual chlorine, cool do...

Embodiment 2

[0027] Add 80kg of deionized water into a 100L chlorination reaction kettle, and evenly spray 600g of glycerol aqueous solution with a mass ratio of 10% on the surface of 10kg of chlorinable PVC special resin QS-C65, and then add it to the chlorination reaction kettle , start the stirring device, the PVC resin is quickly and evenly suspended in the water phase, add 150g of peroxydicarbonate with a concentration of 40%, use chlorine gas to discharge the air in the kettle, heat up the reactor, slowly feed chlorine gas, and the temperature of the reactor reaches 85°C At about 100°C, the chlorination reaction accelerates, the temperature of the reactor is controlled at 100°C, the rate of chlorine flow is 50g / min, the pressure of the reactor is maintained at 0.2-0.4MPa, and when the amount of chlorine flow reaches 6.8kg, the flow of chlorine is stopped and a terminator with a concentration of 20% is added 200g of diethylhydroxylamine, after 10 minutes, vacuumize to remove residual c...

Embodiment 3

[0029] Add 80kg of deionized water into a 100L chlorination reaction kettle, and evenly spray 129g of glycerin aqueous solution with a mass ratio of 70% on the surface of 15kg of chlorinable PVC special resin QS-C65, and then add it to the chlorination reaction kettle , start the stirring device, the PVC resin is quickly and evenly suspended in the water phase, add 150g of peroxydicarbonate with a concentration of 40%, use chlorine gas to discharge the air in the kettle, heat up the reactor, slowly feed chlorine gas, and the temperature of the reactor reaches 85°C At about 100°C, the chlorination reaction accelerates, the temperature of the reactor is controlled at 100°C, the rate of chlorine flow is 50g / min, the pressure of the reactor is maintained at 0.2-0.4MPa, and when the amount of chlorine flow reaches 6.8kg, the flow of chlorine is stopped and a terminator with a concentration of 20% is added 200g of diethylhydroxylamine, after 10 minutes, vacuumize to remove residual c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com