Track type greenhouse tunnel furrowing machine

A trencher, track-type technology, applied in the field of agricultural machinery, can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

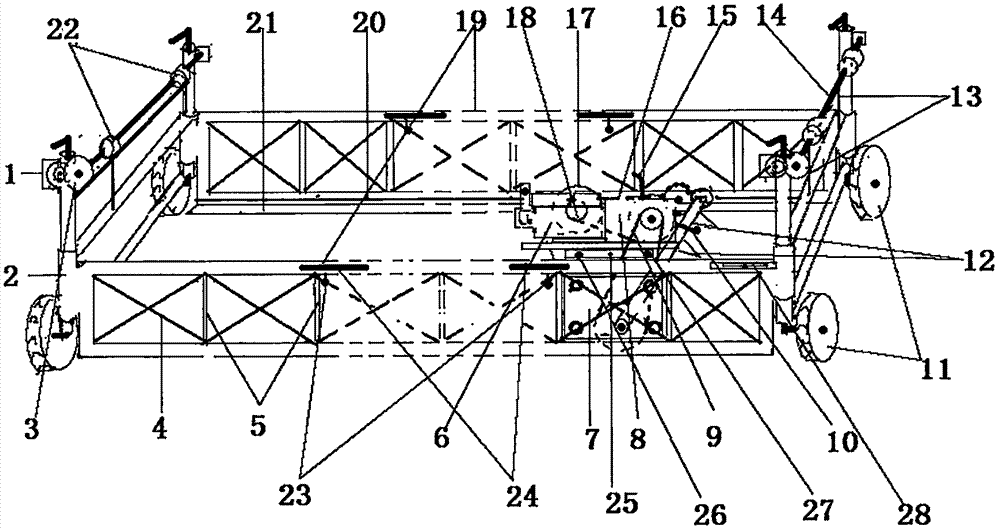

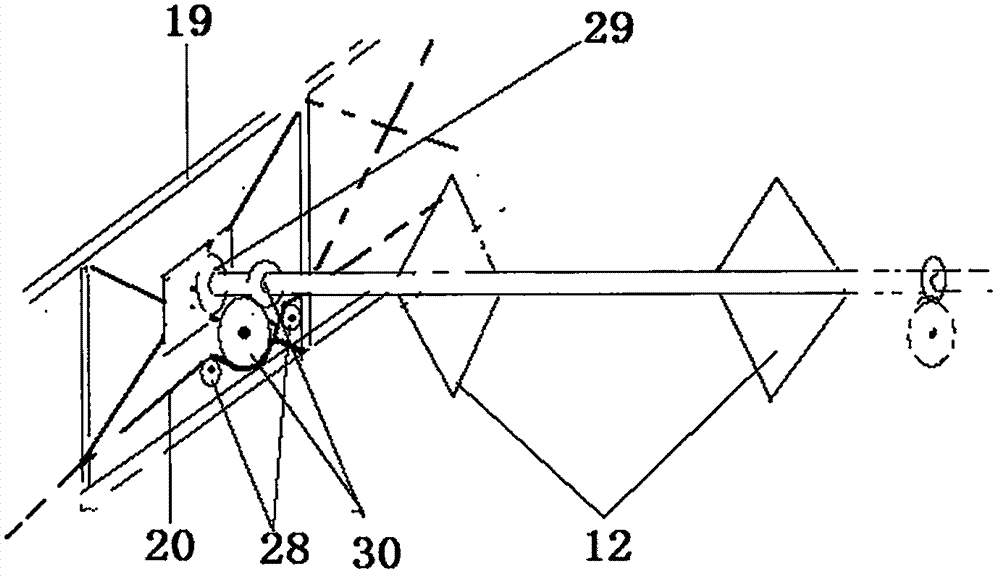

[0011] A track-type greenhouse arch ditching machine, the main feature of which is: a rail frame (19) that can be raised and lowered. The four corners of the track frame (19) are provided with lifting sleeves (2), which are movably sleeved on four vertical pipes. , A thin tube is inserted in the vertical tube. The lower end of the thin tube is equipped with a bracket universal wheel (11), and the device bracket universal wheel (11) can be used with the rear wheel of an electric vehicle. The vertical tube is equipped with a small reduction motor, a small motor gear When the lifting driving wheel (3) is engaged, when the lifting driving wheel (3) rotates, the traction sheave (22) lifts or lowers the track frame through the lifting traction rope (13); the track (21) is equipped with the opener spindle frame (7) ), the main shaft is equipped with two ditching parts (12), the rotary power of the ditching part (12) is provided by the diesel engine (6) through the clutch and gearbox de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com