Straight ball base of V-type track bar assembly

A thrust rod and ball seat technology, applied to the direction of the cantilever, suspension, shaft and bearing installed on the pivot, can solve the problems of many scattered parts, poor working conditions, low efficiency, etc., and achieve reasonable structure composition and processing Easy to make, safe and reliable to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

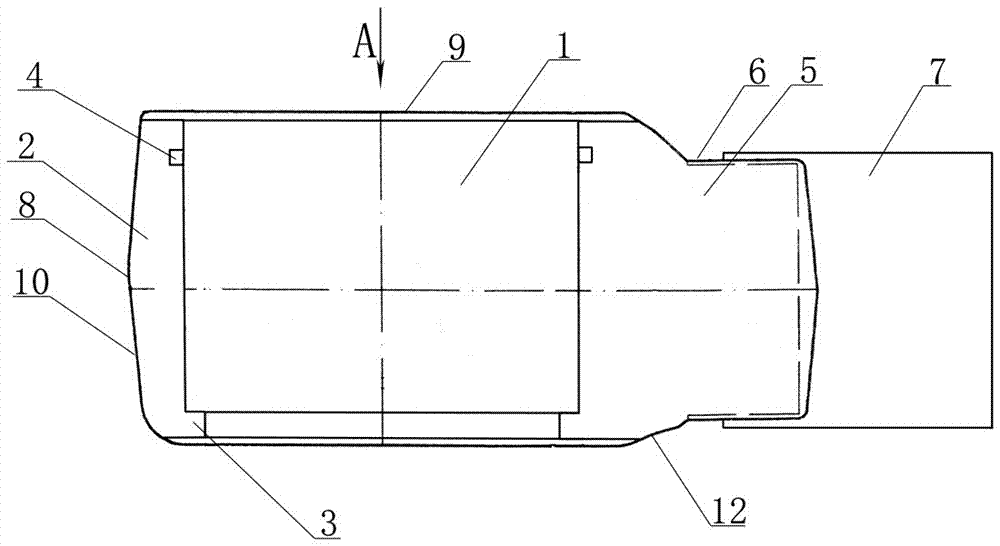

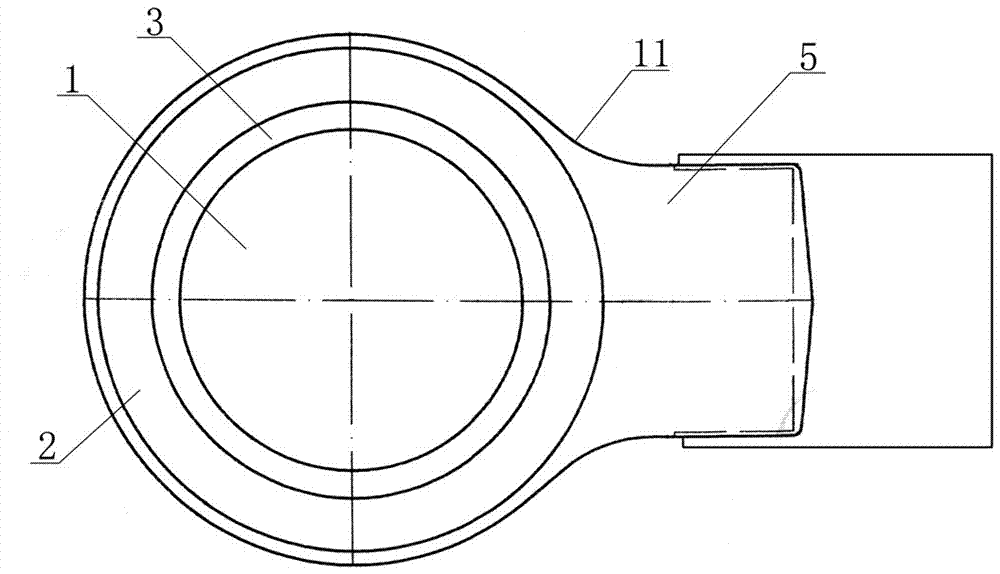

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a straight ball seat of a V-shaped thrust rod assembly according to the present invention includes a straight ball seat body 2 that is forged and finished, and a spherical pin column-shaped through hole 1 is arranged in the middle, and the straight ball seat The inner end of the cylindrical through hole 1 of the body 2 is processed with a protruding ring 3 for the stop of the spherical pin, and the inner end of the other side is processed with a groove 4 for the retaining ring to be embedded for positioning and fixing the spherical pin. The outer wall end of the body 2 is forged with an integrally formed cylindrical connecting end 5 through a circular arc transition, and a reduced-diameter cylindrical connecting section 6 is processed on the cylindrical connecting end 5, and a diameter-reducing cylindrical connecting section 6 is sleeved with a The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com