Diesel engine system and control method

A technology of diesel engine and control method, which is applied in the direction of combustion engine, machine/engine, mechanical equipment, etc., can solve the problem of limited diesel mixing effect, and achieve the effects of easy design and implementation, increased fuel injection pressure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

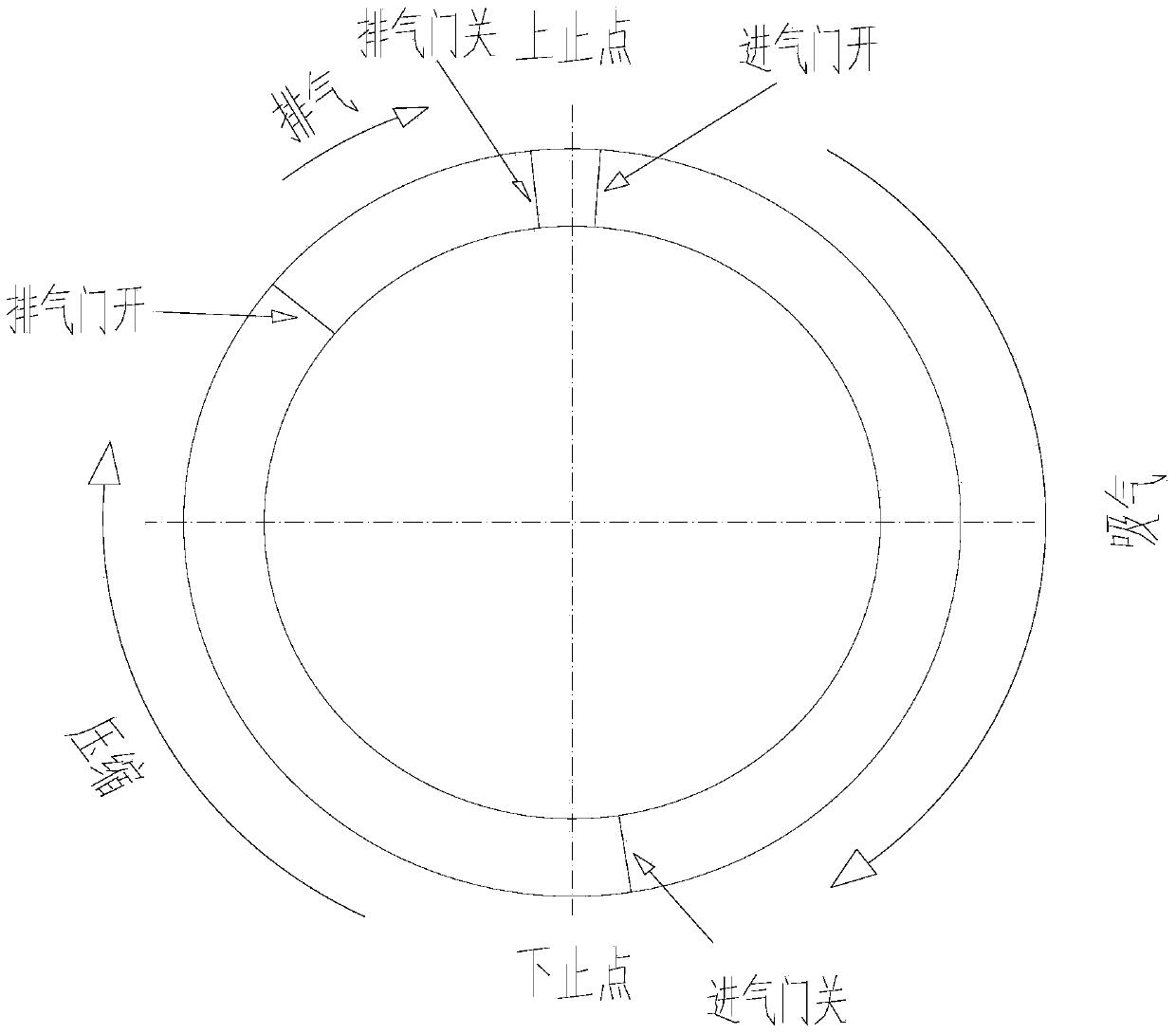

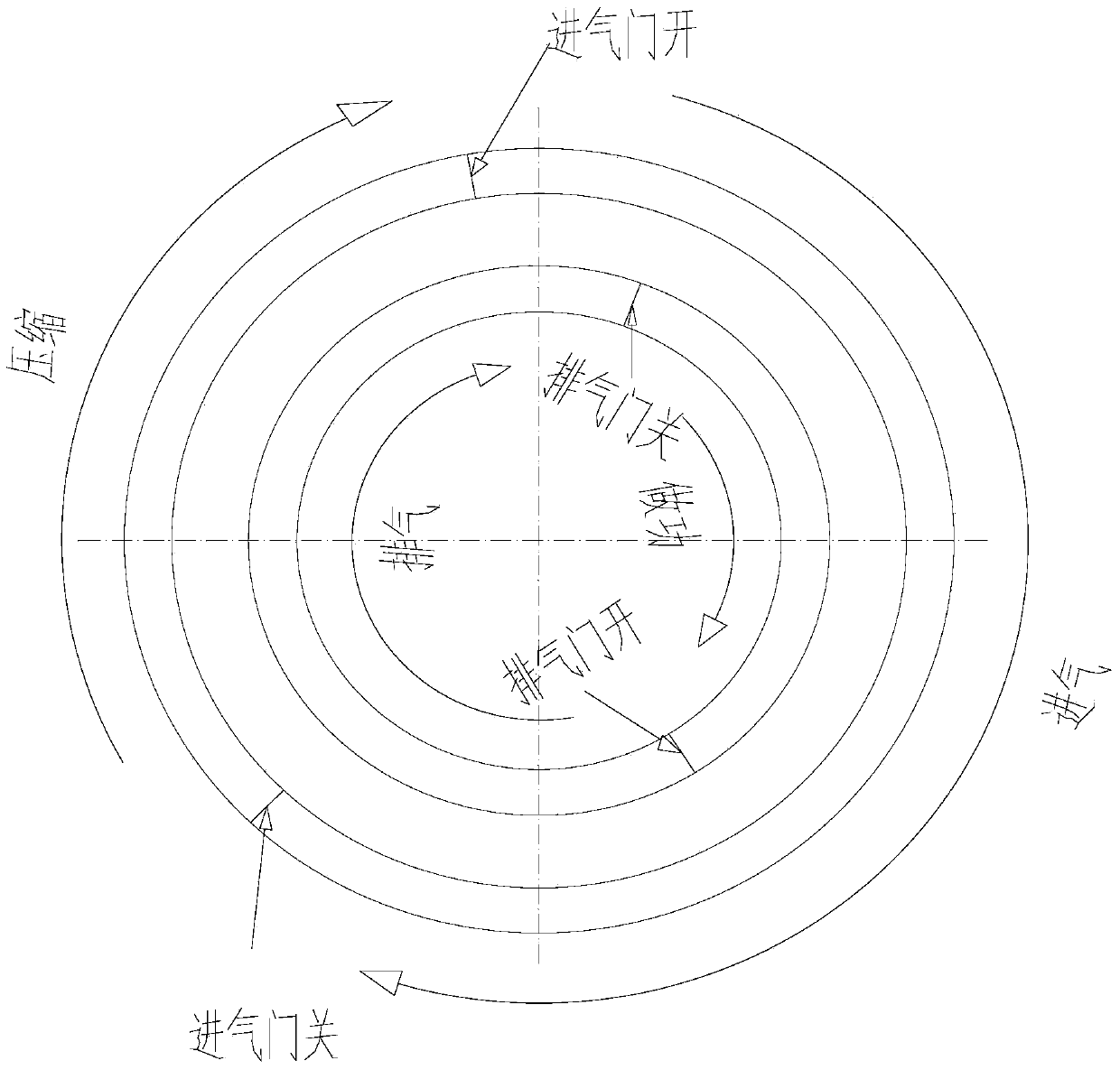

[0040] The invention relates to an air intake treatment device of a diesel engine, which is arranged upstream of the intake air of the diesel engine to form air supply to the diesel engine. The cylinder block of the oil injector is formed with a first air intake port and a first exhaust port communicated with the air intake port of the diesel engine on the cylinder block. The air intake treatment device also includes a compression device cooperating with the cylinder body, and the compression device is configured when the first air intake port on the cylinder body is opened and the first exhaust port is closed, and the fuel injector sprays oil into the cavity. , sucking air into the cavity, so that the air and fuel form a fuel-air mixture; and when the first air inlet is closed and the first exhaust port is opened, the compression device compresses the fuel-air mixture in the cavity, And before the fuel-air mixture is compressed and ignited, it is delivered from the first exha...

Embodiment 2

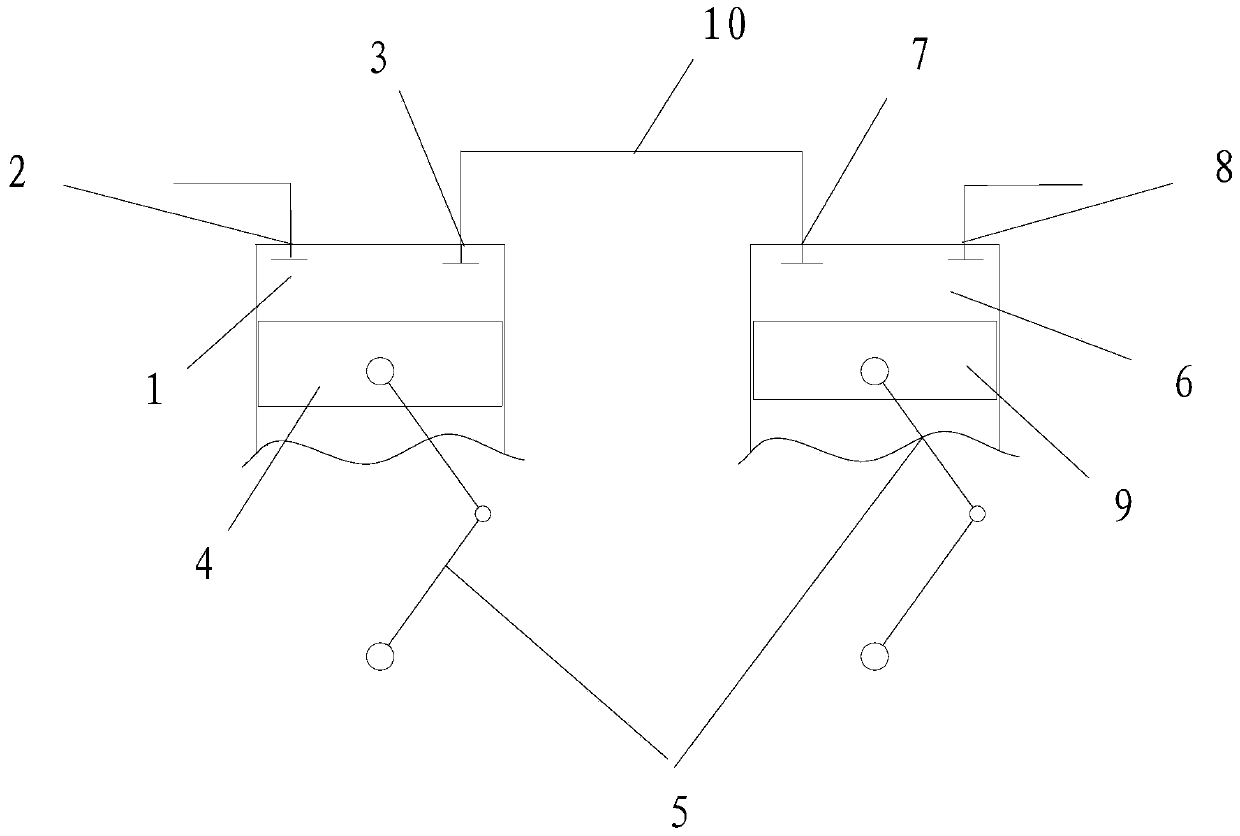

[0050] This embodiment relates to a diesel engine system, in which the intake air treatment device of the diesel engine as described in Embodiment 1 is arranged upstream of the intake air of the engine. Specifically, in this embodiment such as Figure 4 As shown in , the premixing cylinder 1 supplies air to two working cylinder bodies, and for the convenience of description, the two working cylinder bodies are respectively called the first working cylinder 61 and the second working cylinder 62 . The volume of the premixing cylinder 1 is greater than the volumes of the first working cylinder 61 and the second working cylinder 62 .

[0051] In this embodiment, two first air inlets and two first exhaust ports are arranged on the premixing cylinder 1. Similarly, two first working cylinders are also respectively provided with two first working cylinders on the first working cylinder 61. port and two exhaust ports of the first working cylinder, two second working cylinder air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com