Gangue hollow insulating brick

A technology of thermal insulation bricks and coal gangue, which is applied in the field of building materials, can solve the problems of poor sealing and thermal insulation, laborious transportation and handling, and the volume and weight of solid bricks, and achieve good thermal insulation, low manufacturing costs, and fast and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

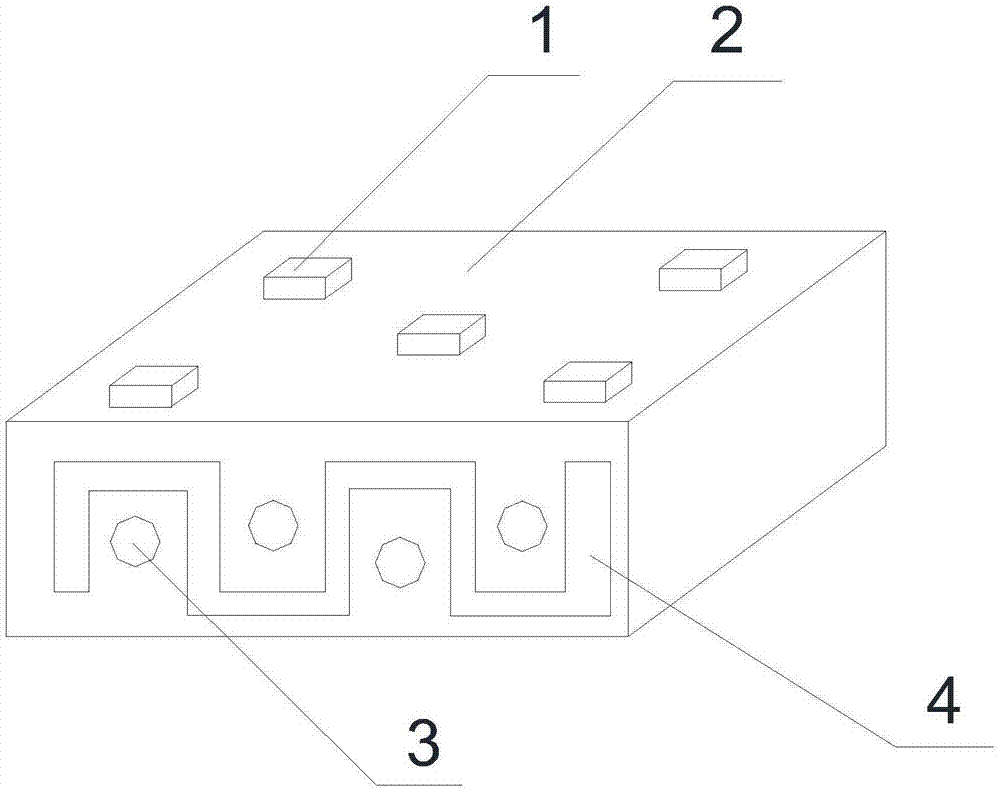

[0013] Such as figure 1 As shown, a coal gangue hollow insulating brick of the present invention comprises a brick body, a bump 1 is provided on the upper surface of the brick body 2, and a groove corresponding to the position of the bump 1 is provided on the lower surface of the brick body 1 (accompanying drawing (not shown in ), a first through hole 3 and a second through hole 4 are arranged on the front and rear sides of the brick body 1, and the second through hole 4 is filled with heat insulating material.

[0014] As a preferred mode of the present invention for the above technical solution, there are five bumps 1 in total, which are respectively arranged at the four corners and the middle of the brick body 1, so as to facilitate positioning and connection.

[0015] As another preferred form of the above technical solution in the present invention, the first through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com