A kind of installation structure of building prefabricated wall

An installation structure and prefabricated technology, applied in building components, building structures, buildings, etc., can solve the problems of long construction period, difficult assembly, and difficult to repair, so as to shorten the construction period, avoid destructive disassembly, and facilitate repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

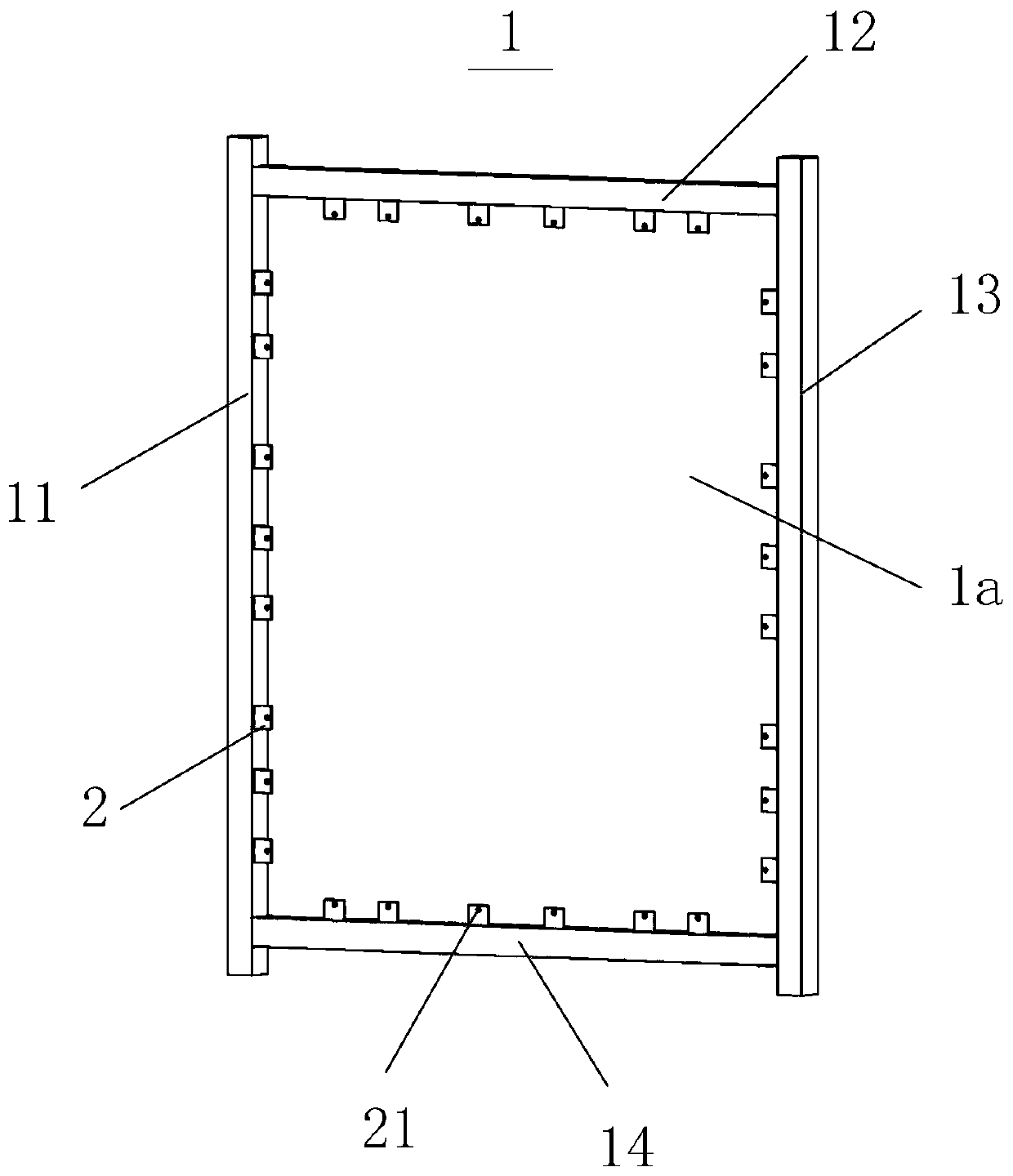

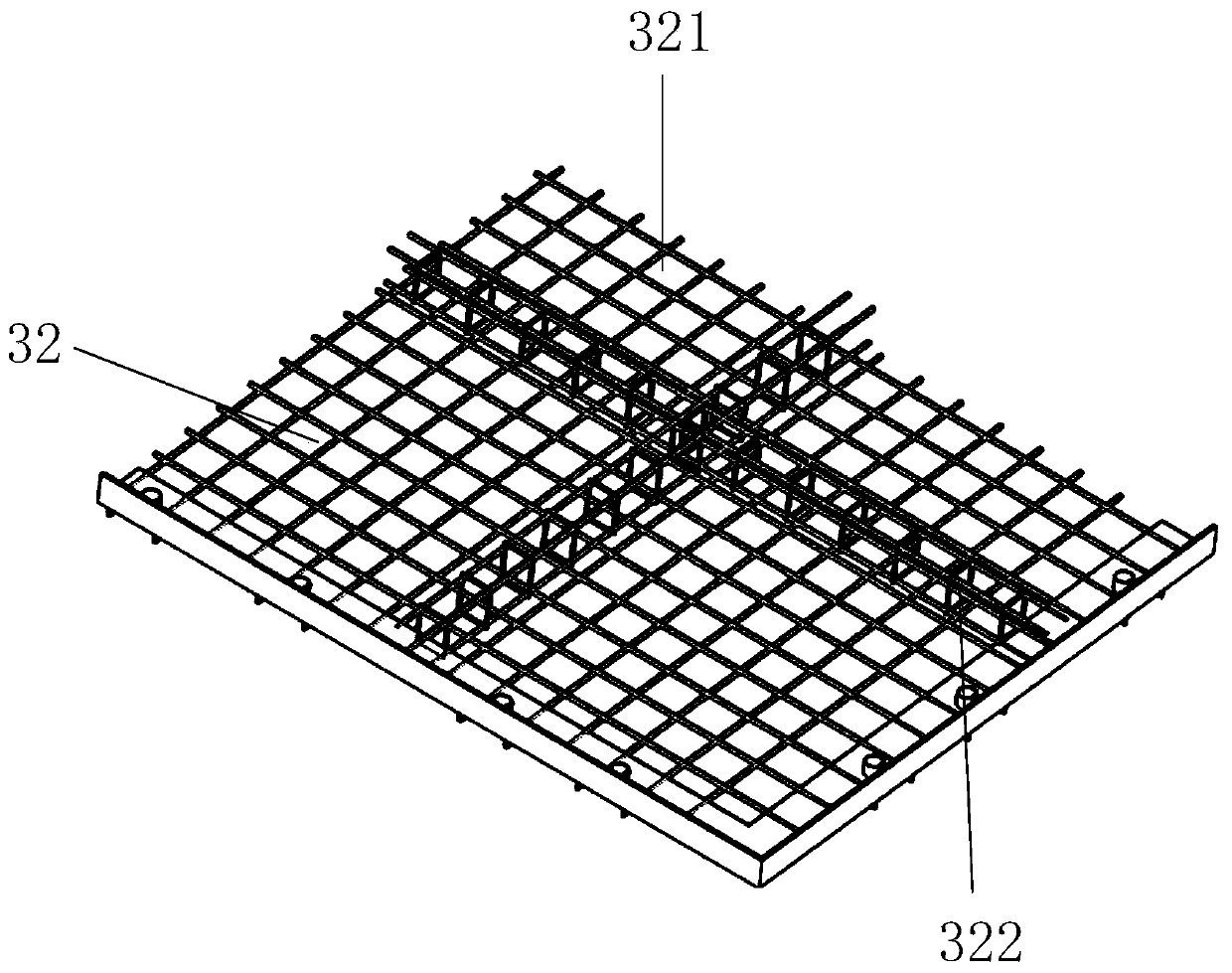

[0031] Such as Figure 1 to Figure 4 As shown, the figure schematically shows that the installation structure 100 of the prefabricated building wall includes a light steel frame 1 , ear plates 2 and ribbed wall panels 3 .

[0032] In the embodiment of the present application, the overall shape of the light steel frame 1 is similar to a rectangle or a square, and an ear plate 2 extending toward the hollow area 1a of the light steel frame 1 is provided on the inner side of the light steel frame 1 . It should be noted that the overall shape of the light steel frame 1 is not limited to the above-mentioned cases, and it can also be reasonably designed according to actual needs.

[0033] In one embodiment, the ear plate 2 can be configured as a rectangular, square or elliptical plate-shaped structure, which mainly plays the role of supporting and fixing the ribbed wall panel 3, so that the densely ribbed wall panel 3 can be firm ground fixed on the light steel frame 1.

[0034] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com