Multifunctional post-processing device for cloth

A post-processing device and multi-functional technology, which is applied in the direction of textile material equipment configuration, spray/jet textile material treatment, liquid/gas/steam removal by air jet method, etc., can solve the waste of power resources, affect the aesthetics, increase the Factory power consumption and other issues, to achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

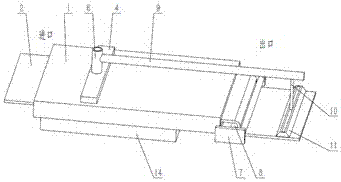

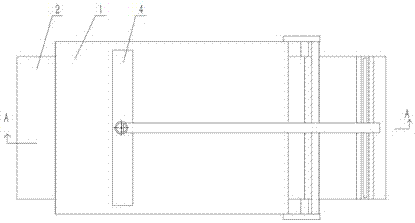

[0016] Such as Figure 1-3 As shown, the cloth multifunctional post-processing device includes a rectangular hollow pipe 1, a cloth 2 passing through the pipe 1 and moving horizontally, the pipe 1 is provided with an inlet and an outlet, and the top surface of the pipe 1 is formed with an installation groove 3, An air-collecting box 4 is fixed in the installation groove 3, and the bottom surface of the air-collecting box 4 is formed with an air jet notch 5, and the top surface of the air-collecting box 4 is fixed with an air intake pipe 6 connected to an air compressor. A drying assembly is provided at the outlet end of the pipeline 1, and a cooling assembly is provided behind the drying assembly.

[0017] Specifically, the drying assembly includes mounting plates 7 on both sides of the outlet end of the fixed pipeline 1 and two heating pipes 8 fixed between the mounting plates 7 .

[0018] Specifically, the cooling assembly includes a shunt pipe 9 arranged horizontally and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com