A seabuckthorn leaf polypeptide and its preparation method

A technology of seabuckthorn leaf and enzymatic hydrolysis, which is applied in the field of food processing, can solve the problems such as no report on the preparation method of seabuckthorn leaf polypeptide, achieve good market application prospects, produce no toxic substances, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 preparation method of seabuckthorn leaf polypeptide of the present invention

[0025] (1) Pretreatment: crush seabuckthorn leaves, mix with boric acid buffer according to the ratio of 1g:50mL of material to liquid, adjust the pH value to 10, put it in a constant temperature water bath at 90°C to inactivate the enzyme for 10min, cool to 45°C, Get the pretreatment solution;

[0026] (2) Enzymolysis: Add alkaline protease to the pretreatment solution, the enzyme addition amount is 14000U / g, put it in a constant temperature water bath at 45°C, and enzymolyze it for 2 hours. After the reaction is completed, put it in a water bath at 90°C to kill the enzyme. Cool to room temperature to obtain the enzymatic hydrolysis solution;

[0027] (3) Clarification: centrifuge the enzymolysis solution at 5000r / min for 10min, take the supernatant in a container, and obtain the polypeptide solution.

Embodiment 2

[0028] Embodiment 2 preparation method of seabuckthorn leaf polypeptide of the present invention

[0029] (1) Pretreatment: crush seabuckthorn leaves, mix with boric acid buffer according to the material-liquid ratio of 1g:30mL, adjust the pH value to 8, put it in a constant temperature water bath at 70°C to inactivate the enzyme for 10min, cool to 55°C, Get the pretreatment solution;

[0030] (2) Enzymolysis: Add alkaline protease to the pretreatment solution, the enzyme addition amount is 10000U / g, put it in a constant temperature water bath at 40°C, and enzymolyze it for 4 hours. After the reaction is completed, put it in a water bath at 90°C to kill the enzyme. Cool to room temperature to obtain the enzymatic hydrolysis solution;

[0031] (3) Clarification: centrifuge the enzymolysis solution at 5000r / min for 10min, take the supernatant in a container, and obtain the polypeptide solution.

Embodiment 3

[0032] Embodiment 3 preparation method of seabuckthorn leaf polypeptide of the present invention

[0033] (1) Pretreatment: Pulverize seabuckthorn leaves, mix with boric acid buffer according to the ratio of 1g:60mL of material to liquid, adjust the pH value to 12, put it in a constant temperature water bath at 90°C for 10 minutes, and cool to room temperature to obtain pretreatment liquid;

[0034] (2) Enzymolysis: Add alkaline protease to the pretreatment solution, the enzyme addition amount is 18000U / g, put it in a constant temperature water bath at 55°C, and enzymolyze it for 2 hours. After the reaction is completed, put it in a water bath at 100°C to kill the enzyme. Cool to room temperature to obtain the enzymatic hydrolysis solution;

[0035] (3) Clarification: centrifuge the enzymolysis solution at 5000r / min for 10min, take the supernatant in a container, and obtain the polypeptide solution.

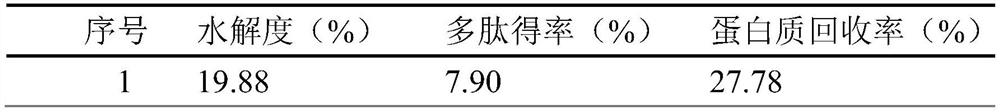

[0036] Prove beneficial effect of the present invention by concrete experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com