Method for separating and purifying m-cresol and p-cresol through complexation crystallization

A technology of p-cresol and crystallization method, which is applied in the field of separation and purification of m/p-cresol mixture by complex crystallization method, can solve the problems of expensive equipment and operation costs, waste of raw materials, high equipment requirements, etc., achieve mild temperature conditions and improve recovery The effect of low efficiency and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

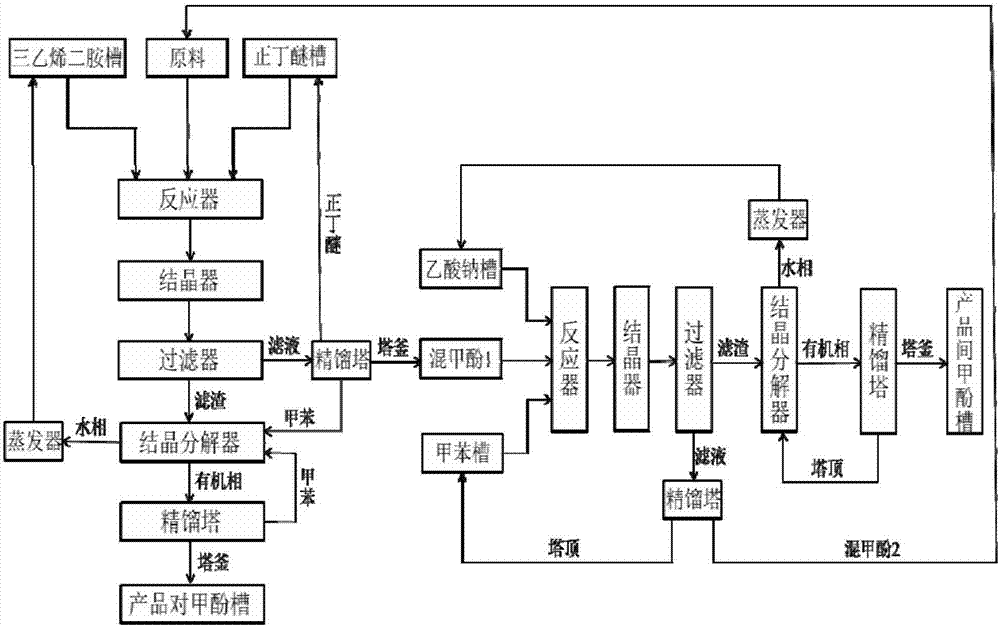

Method used

Image

Examples

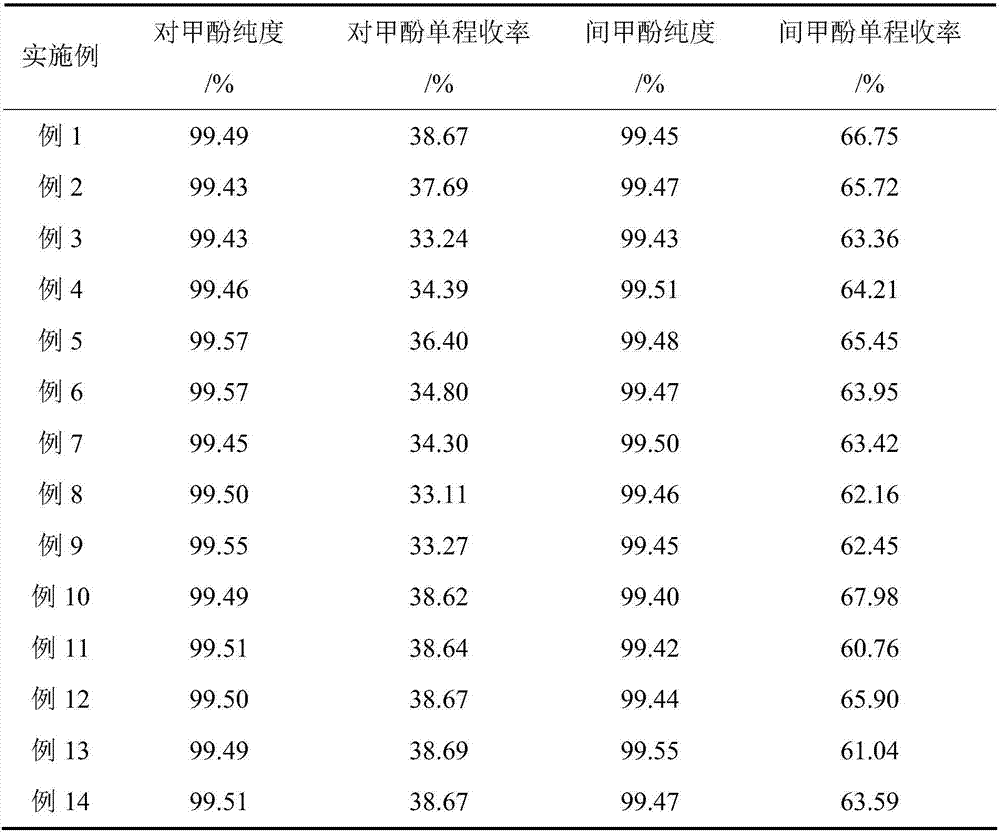

Embodiment 1

[0028] 1). P-cresol complex crystallization: mix the raw materials with m / p-cresol (60% m-cresol, 40% p-cresol) and add it into the reactor after weighing the volume. The volume ratio of the mixed cresol with the raw material is Add 2.0:1 solvent n-butyl ether into the reactor, and mix the two evenly to completely dissolve cresol in n-butyl ether. Then add the complexing agent DABCO·6H which is 0.9:1 with p-cresol molar ratio 2 O, heated in a water bath at 90°C and stirred vigorously for 2h. After the reaction is over, transfer the reaction solution into a crystallizer for cooling and crystallization. The cooling rate is 10°C / h, and the crystallization termination temperature is -10°C. After reaching -10°C, keep the constant temperature for 3 hours;

[0029] 2). Filtration, washing and rectification: Use a vacuum pump to filter the reaction solution after cooling and crystallization to obtain the filtrate and filter cake, and then use -10°C toluene as a detergent to wash and ...

Embodiment 2

[0040] Experimental device and operation process are the same as embodiment 1, just step 1) in, complexing agent DABCO 6H 2 O was replaced by DABCO, and the analysis results are shown in Table 1.

Embodiment 3

[0042] The experimental device and operation process are the same as in Example 1, except that in step 1), the volume ratio of the solvent n-butyl ether and the raw material mixed cresol is replaced by 2.5:1, and the added complexing agent DABCO 6H 2 The molar ratio of p-cresol in O and the raw material mixed cresol is changed to 0.8:1, the reaction time is changed to 3h, the cooling rate is 5°C / h, and after reaching -10°C, the constant temperature is kept for 2h; in step 2), each washing The quality of the toluene used is the same as the quality of the filter cake obtained after each suction filtration. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com