Steel-skeleton building material and production method thereof

A production method and technology of steel skeleton, applied in the field of steel skeleton building materials, can solve the problems of unreasonable structural design of steel wire mesh frame, insufficient combination of filling materials, poor mechanical strength, etc. The effect of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

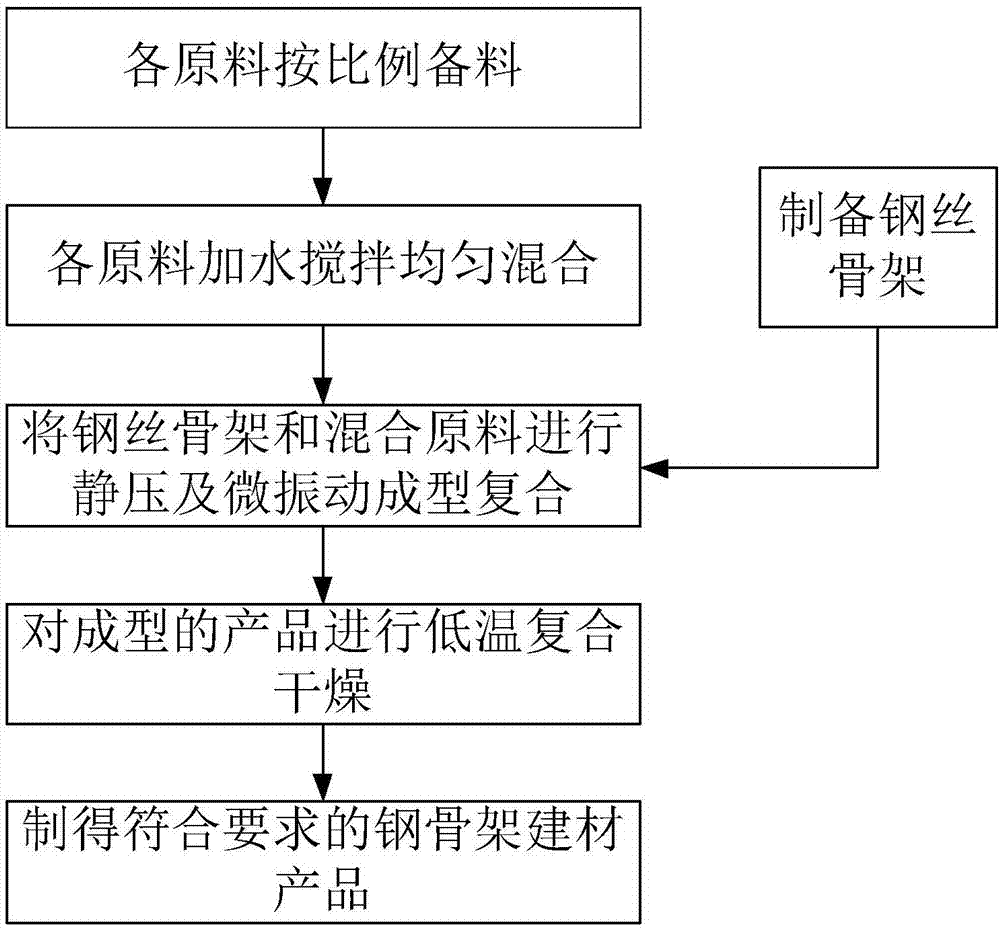

[0049] The steel skeleton building material is a thermal insulation building material product made of cement. It is composed of cement, fly ash, vermiculite, ceramsite, perlite and additives in the following mass ratio, mixed with water, and then formed by static pressure and micro-vibration with a rectangular parallelepiped steel wire skeleton. compounded and dried;

[0050] Cement: 8%, fly ash: 8-10%, vermiculite, ceramsite or perlite or a mixture of at least two kinds thereof: 80%, additives: 2-4%.

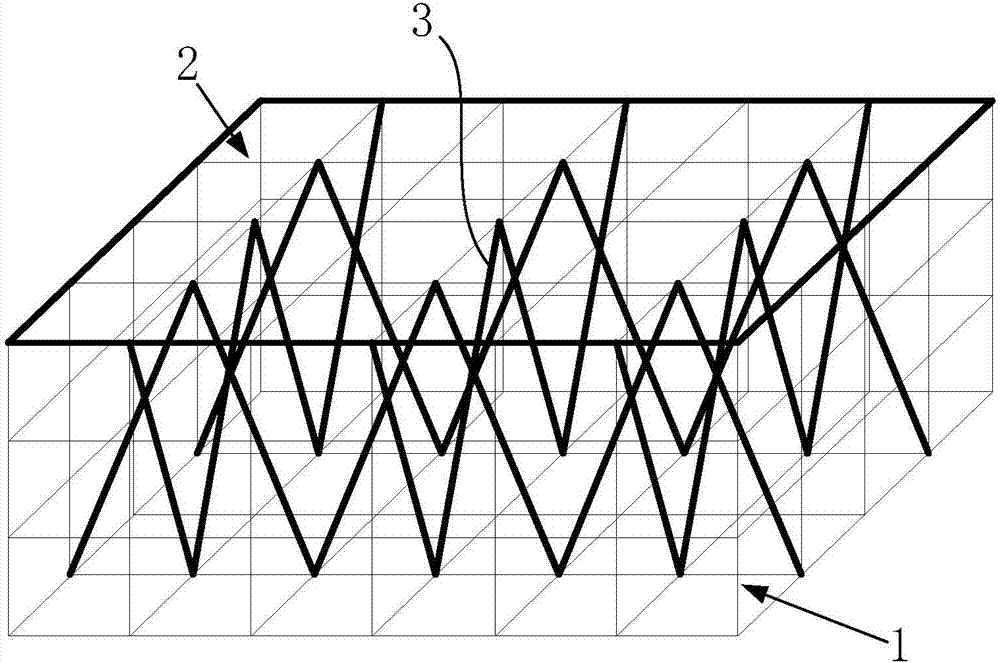

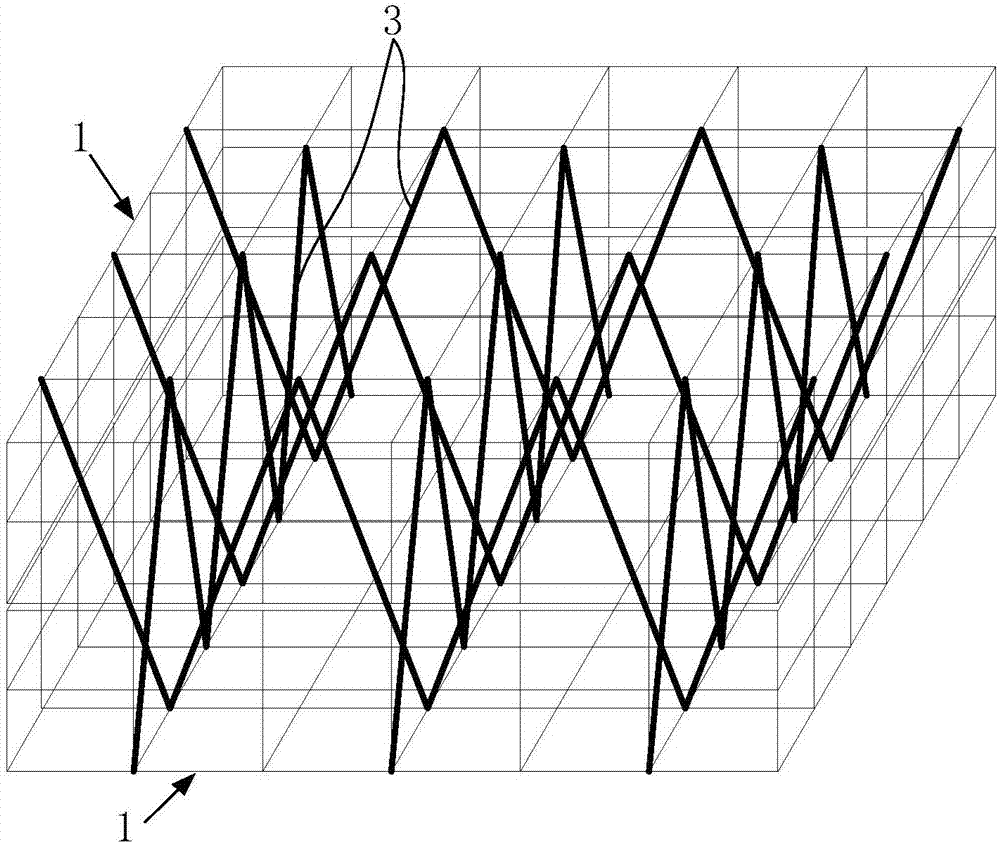

[0051] Wherein, the steel wire skeleton protrudes 1-2 cm from at least one surface of the steel skeleton building material. The steel wire skeleton is composed of an integrated pentahedron frame 1 with a cover net 2, a double-integrated pentahedron frame spliced or a double U-shaped frame spliced, and a plurality of zigzag tendons 3 are evenly distributed in a criss-cross pattern inside it. Such as figure 2 The one-piece pentahedral box-covered mesh form shown, such as i...

Embodiment 2

[0054] The steel frame building material is a non-cement thermal insulation building material product, which is composed of foamable waste, fly ash, foaming agent and additives with water in the following mass ratio, and then compounded with a rectangular parallelepiped steel wire frame by static pressure and micro-vibration molding and dried;

[0055] Foamable waste: 85-90%, fly ash: 8-10%, foaming agent: 1-3%, additives: 1-2%. Wherein, the structure of the steel wire skeleton is the same as that of Embodiment 1.

Embodiment 3

[0057] The steel frame building material is a non-insulation cement product, which is composed of cement, fly ash, available solid waste, adhesives and additives in the following mass ratio, mixed with water, and then formed by static pressure and micro-vibration with a rectangular parallelepiped steel wire frame compounded and dried;

[0058] Cement: 8-10%, fly ash: 10%, usable solid waste: 75-80%, binder: 3-4%, additives: 1-2%, among which, usable solid waste includes slag , engineering waste, industrial and agricultural waste. The structure of the steel wire skeleton is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com