Wooden packaging box feeding device

A wooden packaging and jacking device technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large wooden packaging boxes, low feeding efficiency, accidents, etc., to achieve high automation and reduce The effect of manpower input and fast feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

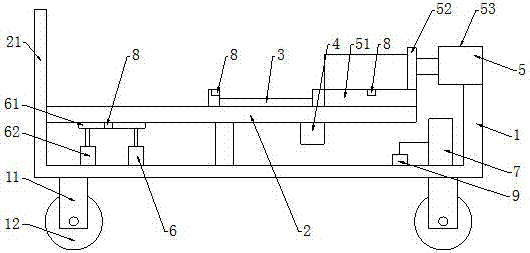

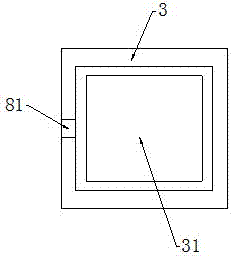

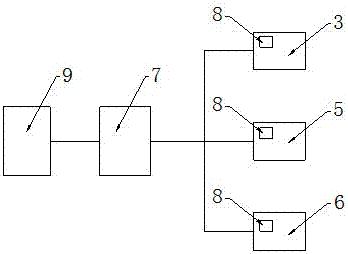

[0018] The present invention relates to a wooden packaging box feeding device, which has a frame 1, a support rod 11 is connected to the bottom of the frame 1, and a universal wheel 12 for moving the frame is connected to the support rod 11, and is arranged above the frame 1. There is a linear guide rail 2, and a PLC control device 7 is arranged in the cavity between the linear guide rail 2 and the frame 1, and the PLC control device 7 is connected with a driving motor 4, a pushing mechanism 5 and a jacking device arranged on the frame 1 6. The driving motor 4 is connected with the material frame 3 that moves on the linear guide rail 2 for moving the wooden packaging box. The push mechanism 5 is arranged on the right side of the linear guide rail 2, and the jacking device 6 is arranged on the lower left side of the linear guide rail 2. The PLC control de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com