Self-aligning chamfering processing mode and equipment

A technology for automatic centering and processing equipment, which is applied in metal processing equipment, metal processing machinery parts, driving devices, etc., and can solve the problem of chamfering of shaft holes or workpiece ends and variable inner hole chamfering. Frequent tool replacement, affecting factory production efficiency and other issues, to achieve the effect of improving the single function, realizing multiple utilization, and avoiding the process of tool replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

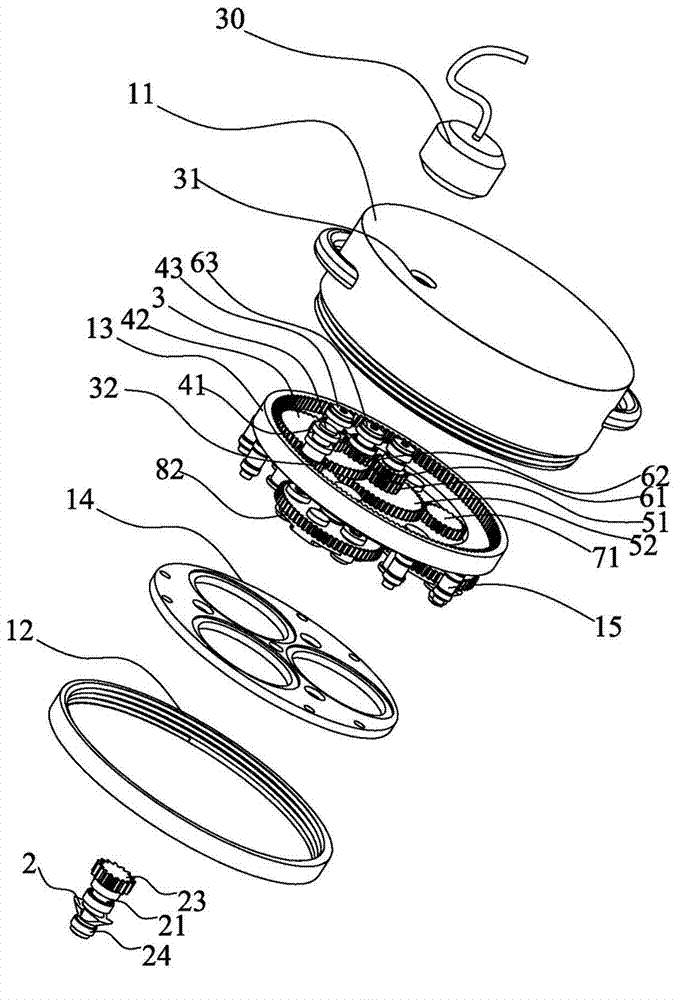

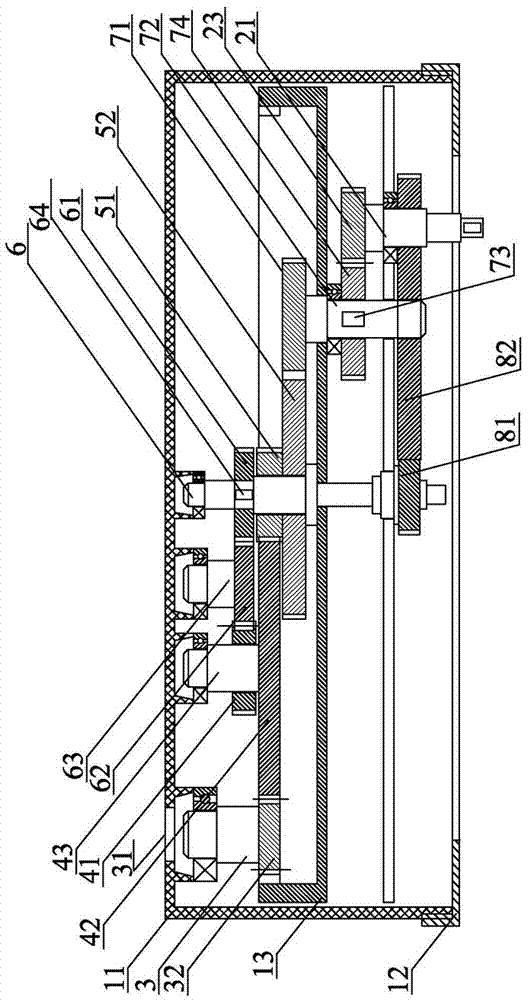

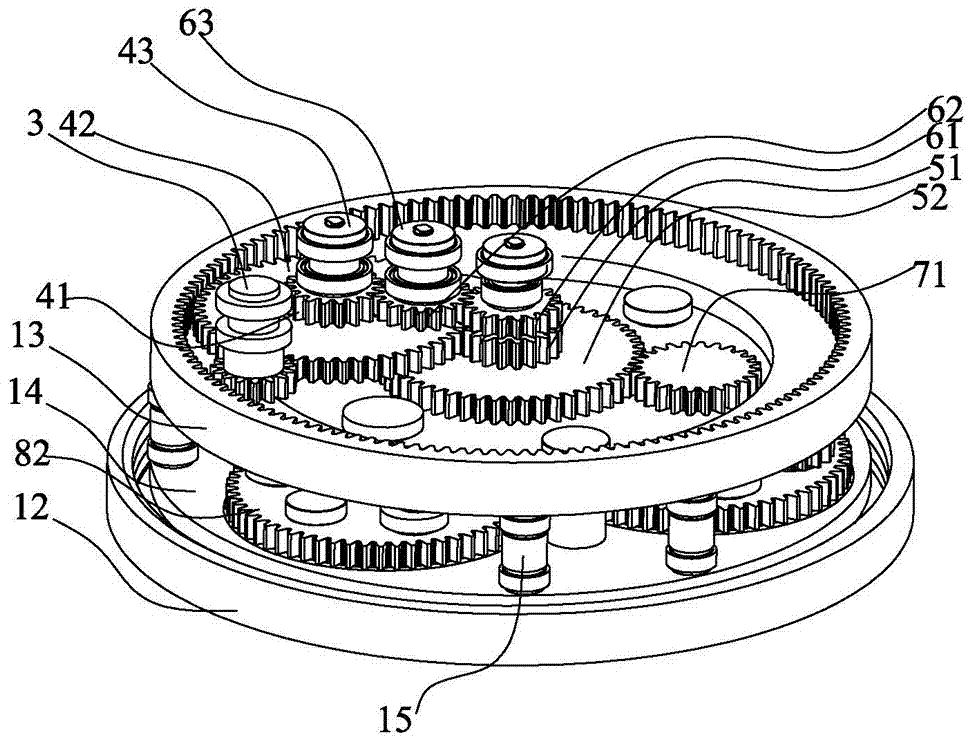

[0046] What the present invention discloses is an automatic centering chamfering processing equipment, such as Figure 1-2 As shown, it is a preferred embodiment of the present invention. The device includes a body, a power source 30, a cutter 2 and a transmission gear set, wherein the power source 30 can be a common pneumatic power source, and the cutter 2 is fixedly installed on the side of a cutter shaft 21. At one end, the cutter shaft 21 is rotatably installed on the transmission gear set, and the transmission gear set is assembled in the body. When the equipment is running, the cutter shaft 21 and the tool 2 can revolve around the center of the inner hole to be processed or the end surface of the workpiece with a variable revolution radius. , the power source 30 drives the cutter shaft 21 and the cutter 2 to rotate at high speed through the transmission gear set. The high-speed rotation of the tool 2 can realize the cutting of the port of the part, and its revolution aro...

Embodiment 2

[0059] Further, in order to avoid changing the revolution radius of the tool due to the pressure of the workpiece or the edge of the inner hole on the tool when the tool is lowered, a ratchet mechanism can be provided between the box plate and the fixed plate, and the clockwise rotation of the planetary gear 82 relative to the central gear 81 can be prevented by the ratchet mechanism. Realize the locking of tool revolution radius.

[0060] Specifically, other structures of the device are the same as those in Embodiment 1, except that any planetary gear 82 is selected to set a ratchet mechanism, such as Figure 8 As shown, in order to ensure that the space distribution in the case is reasonable, the planetary gear 82 that the first gear 71 does not pass through is selected in this embodiment, and a ratchet 91 is fixed at the upper end of any fixed column 15 of the planetary gear, and the upper end of the first gear shaft 72 A ratchet 92 is fixed, and the ratchet 91 abuts agains...

Embodiment 3

[0063] The difference between this embodiment and embodiment two is only the position distribution of the pawls, such as Figure 9 In the present embodiment shown, a ratchet 91 is fixedly and movably installed on the fixed plate 14, because the fixed plate 14 is fixed below the box dish and rotates synchronously with the box dish, the ratchet 91 can also be selected to be fixedly installed on the bottom surface of the box dish. The pawl 91 can be installed in the gap on one side of the meshing part of the planetary gear 82. The pawl 91 can rotate around its installation shaft and reset by the coil spring or spring sleeved on the installation shaft. The claw tip of the pawl 91 is inserted at an acute angle. In the teeth of the planetary gear 82, when the planetary gear 82 moves counterclockwise relative to the wheel box under the drive of the central gear 81, the pawl 91 can rotate under the action of the gear teeth without affecting the progress of the planetary gear. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com