Dehumidification control method of fish fillet seafood tunnel drying system based on heat pump

The technology of a drying system and control method is applied in the preservation of meat/fish, dry preservation of meat/fish, food processing, etc., and can solve the problems of complex process control and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

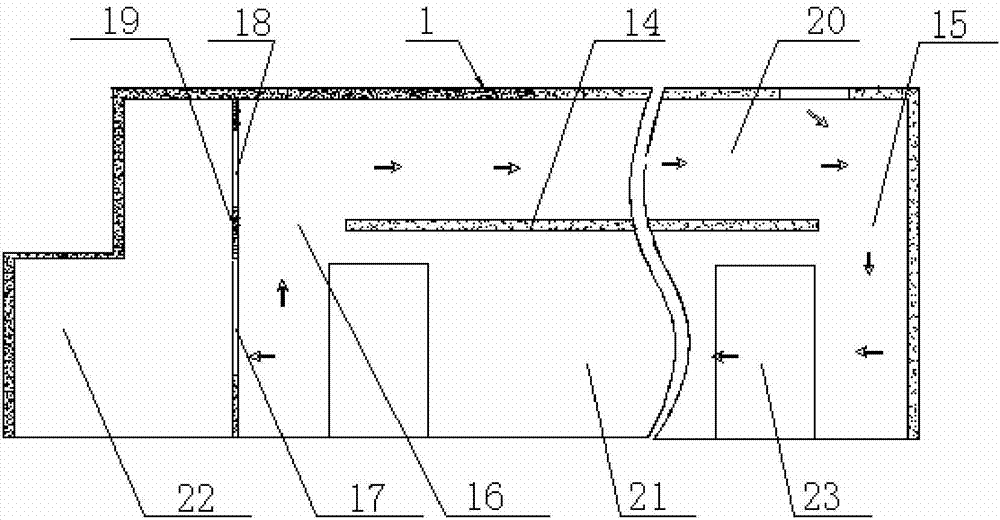

[0065] Such as figure 1 , a tunnel drying system, including a circulating air duct, two 7.5KW 50Hz circulating fans 2 located in the circulating air duct, a 9kw dehumidifying fan 7 located in the circulating air duct, a total heat exchange core 5 located in the circulating air duct and Multiple sets of heat pump units and circulating fans can be arranged side by side, and the present invention can use one or more sets of heat pump units according to the situation.

[0066] The circulation fan is used to force the air in the circulation duct to circulate, to exchange heat of the air, and to make the wind speed in the circulation duct reach 3-6 meters per second, so as to facilitate the distribution of moisture from the material to the air.

[0067] The heat pump unit includes a 40P non-variable frequency compressor, an indoor condenser 3, an outdoor condenser 9, a throttling device, and an evaporator 6, and the outlet of the compressor passes through the indoor condenser 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com