Scratch bacteria production line

A technology of a production line and a scratching device, which is applied in the field of scratching production lines, can solve problems such as reducing the working efficiency of scratching, reducing the utilization rate of working equipment, etc., so as to reduce the working time of scratching, increase output benefits, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

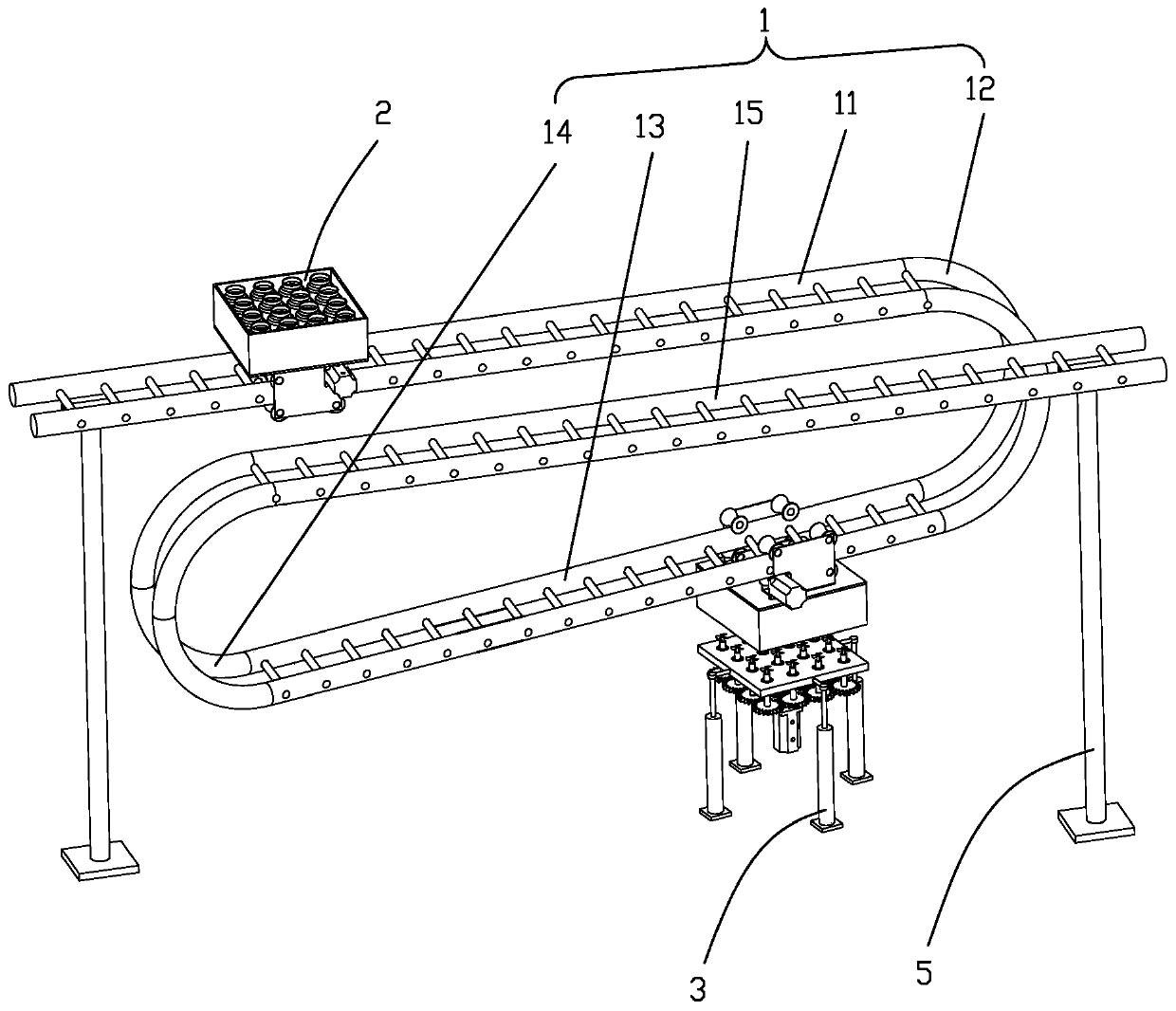

[0039] Such as Figure 1-4 As shown, the fungus scratching production line includes an overturning track 1 , a loading and transporting device 2 , a fungus scratching device 3 , and a support column 5 .

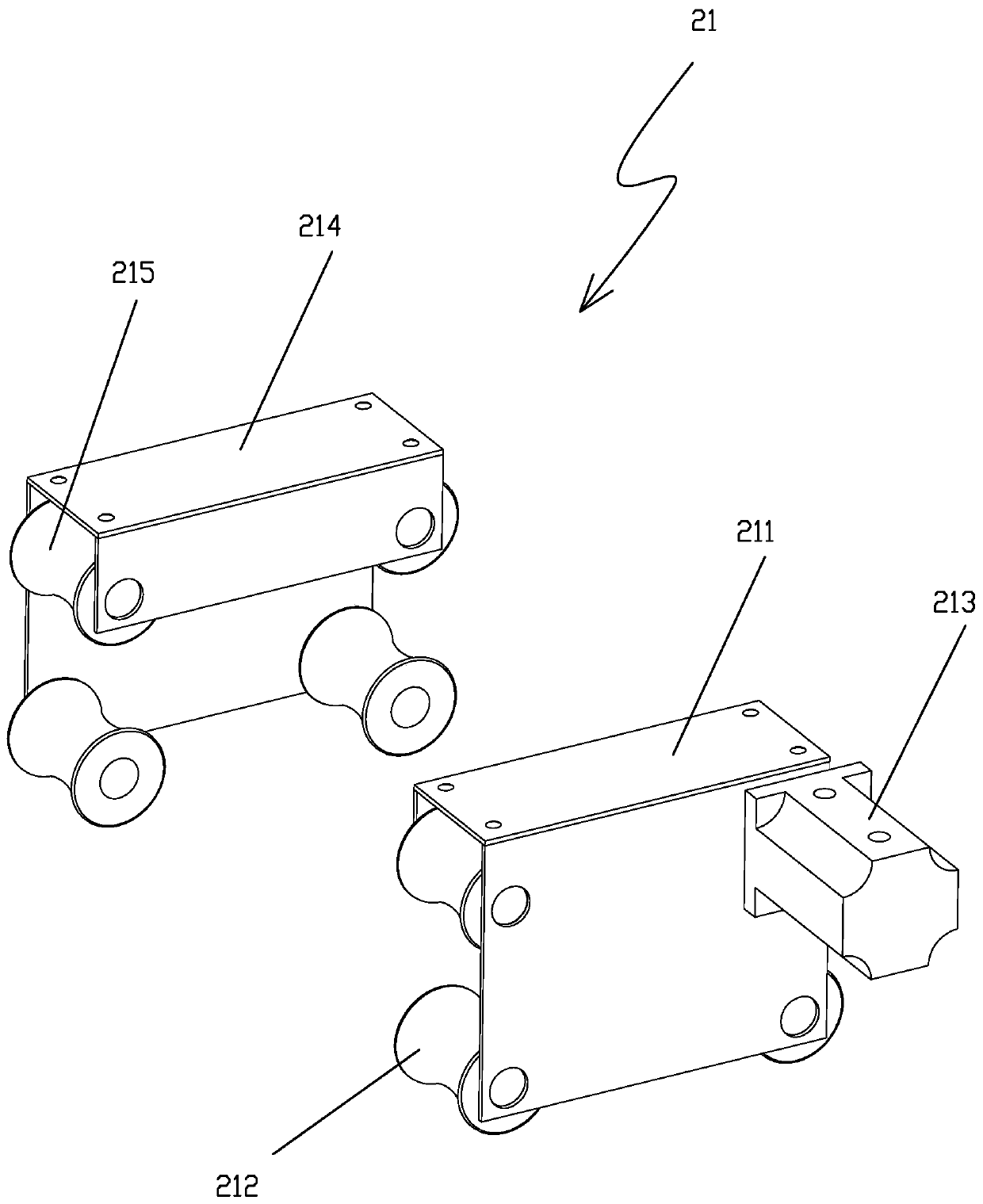

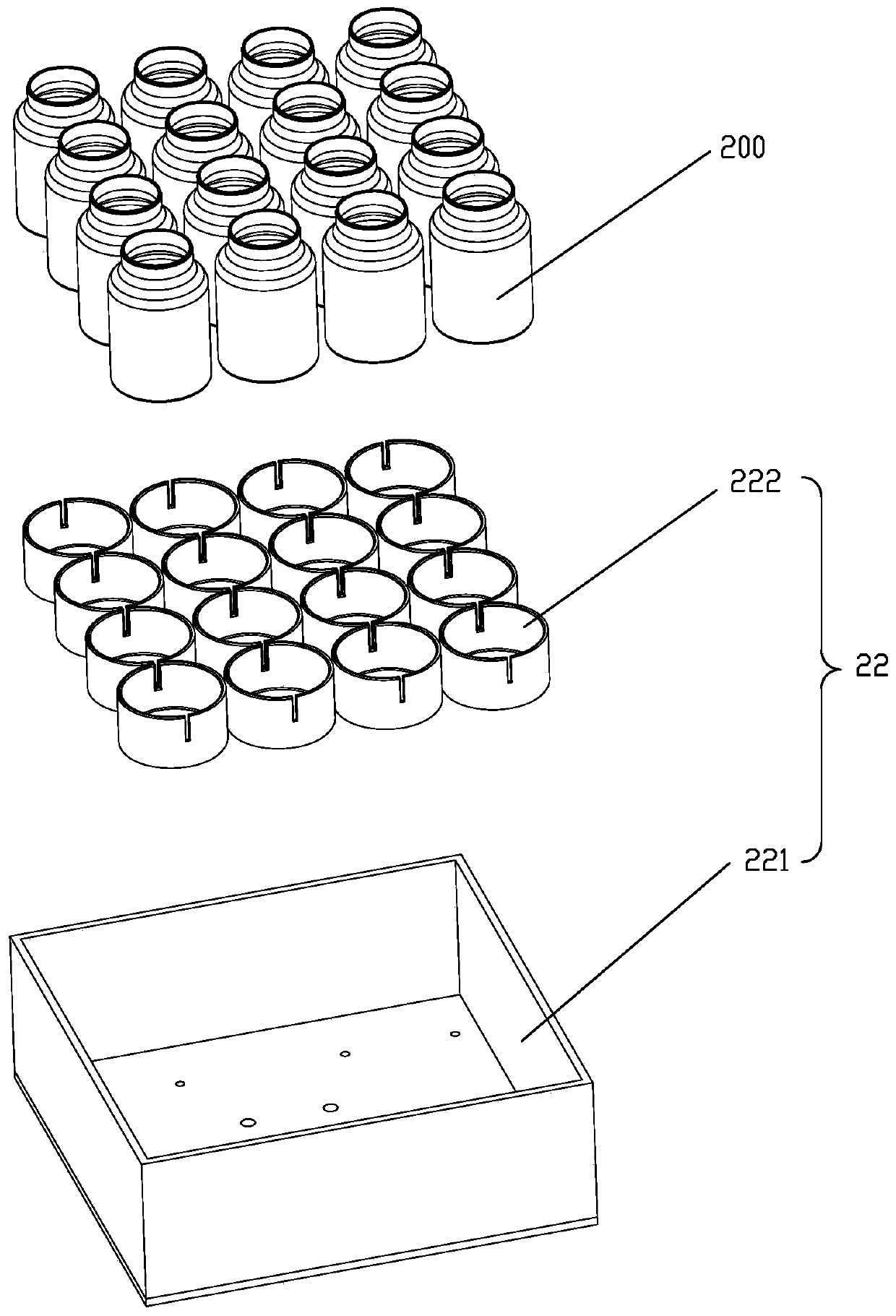

[0040] Specifically, the loading and transporting device 2 is arranged on the overturning track 1 for loading the edible fungus culture bottle 200, and can move along the overturning track 1 and realize overturning, so that the edible fungus culture bottle 200 passes through the mouth of the bottle. Flip from the upward state to the bottle mouth downward state. The fungus scratching device 3 is arranged below the overturning track 1, and when the loading and transporting device 2 moves above the fungus scratching device 4 and the edible fungus culture bottle 200 is in a downward state, the fungus scratching device 3. Lift up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com