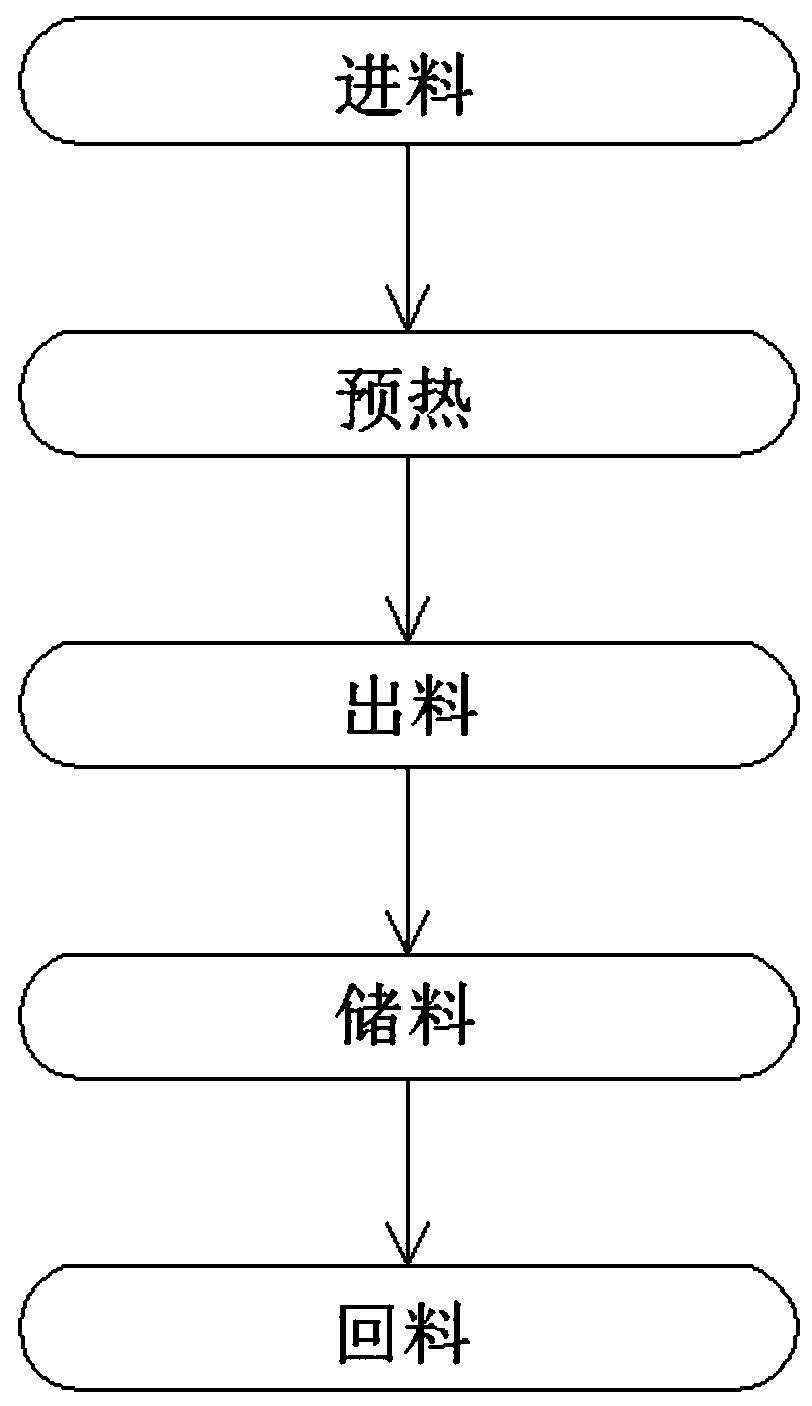

Open type calcium brine preheating process system

An open, brine technology, applied in the application field of heat transfer technology and crystallization technology, can solve the problems of affecting the effective production time, large equipment maintenance, reducing heat transfer coefficient, etc., to save labor costs and water resources, equipment maintenance. Small, reduce the effect of cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

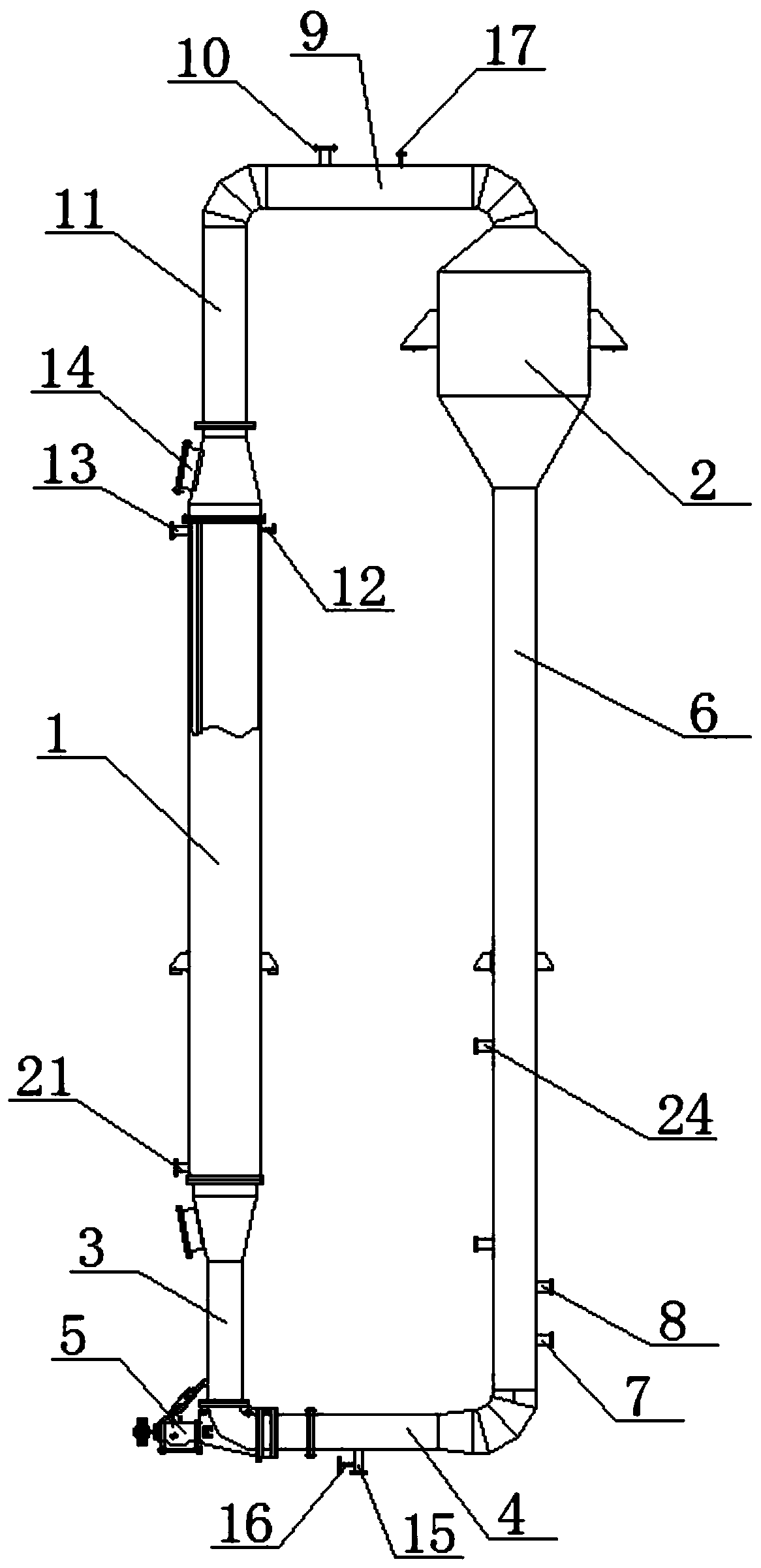

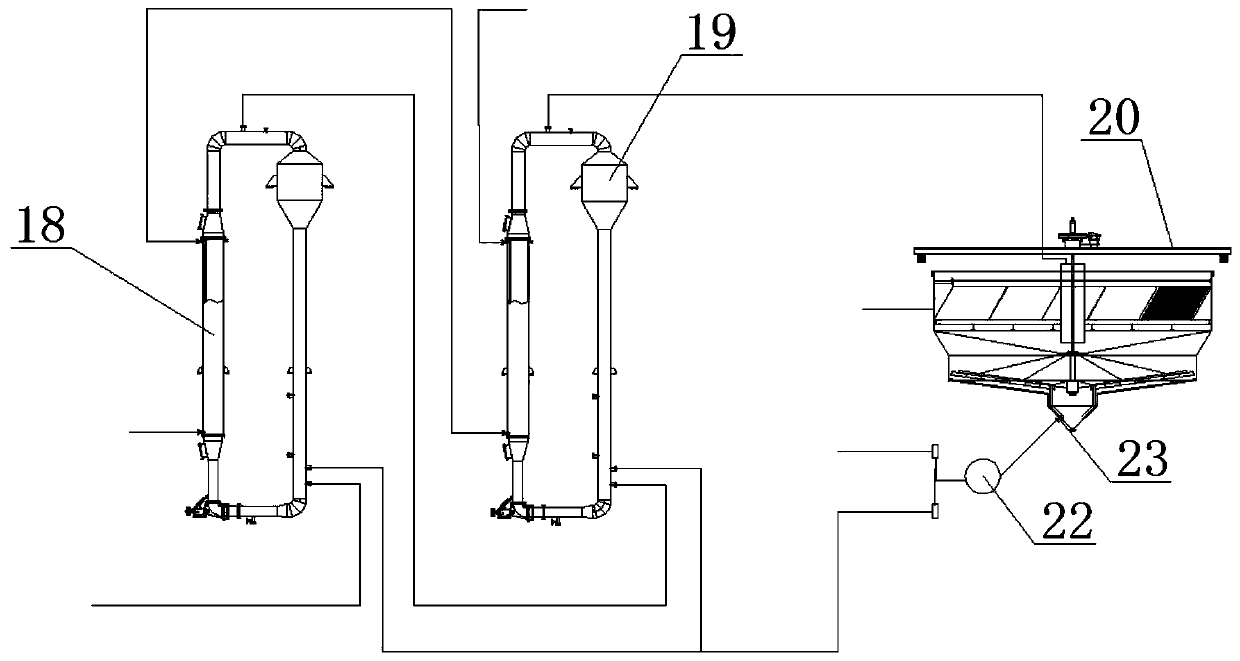

[0022] see Figure 1 to Figure 3 , the present invention provides a technical solution: an open calcium type brine preheating system process, including a primary preheating device 18, a secondary preheating device 19 and a settler 20, the primary preheating device 18 and the secondary Each stage preheating device 19 includes a heat exchanger 1 and a material storage chamber 2. The bottom of the heat exchanger 1 is connected to the lower section 3 of the upper draft pipe through a flange, and one end of the lower section 3 of the upper draft pipe is connected to a lower section 3. The horizontal section 4 of the draft tube, one end of the horizontal section 4 of the lower draft tube is flange-connected and installed with a base material propeller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com