A Life Prediction Method of O-Rubber Seal Ring Based on Multivariate Sample Difference

A rubber sealing ring, multi-sample technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve the problems of large deviation between the predicted results and the actual, and the randomness and dynamics of the product degradation process without considering the individual differences of samples. , to achieve the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] Design of constant stress accelerated degradation test scheme for O-ring rubber sealing ring:

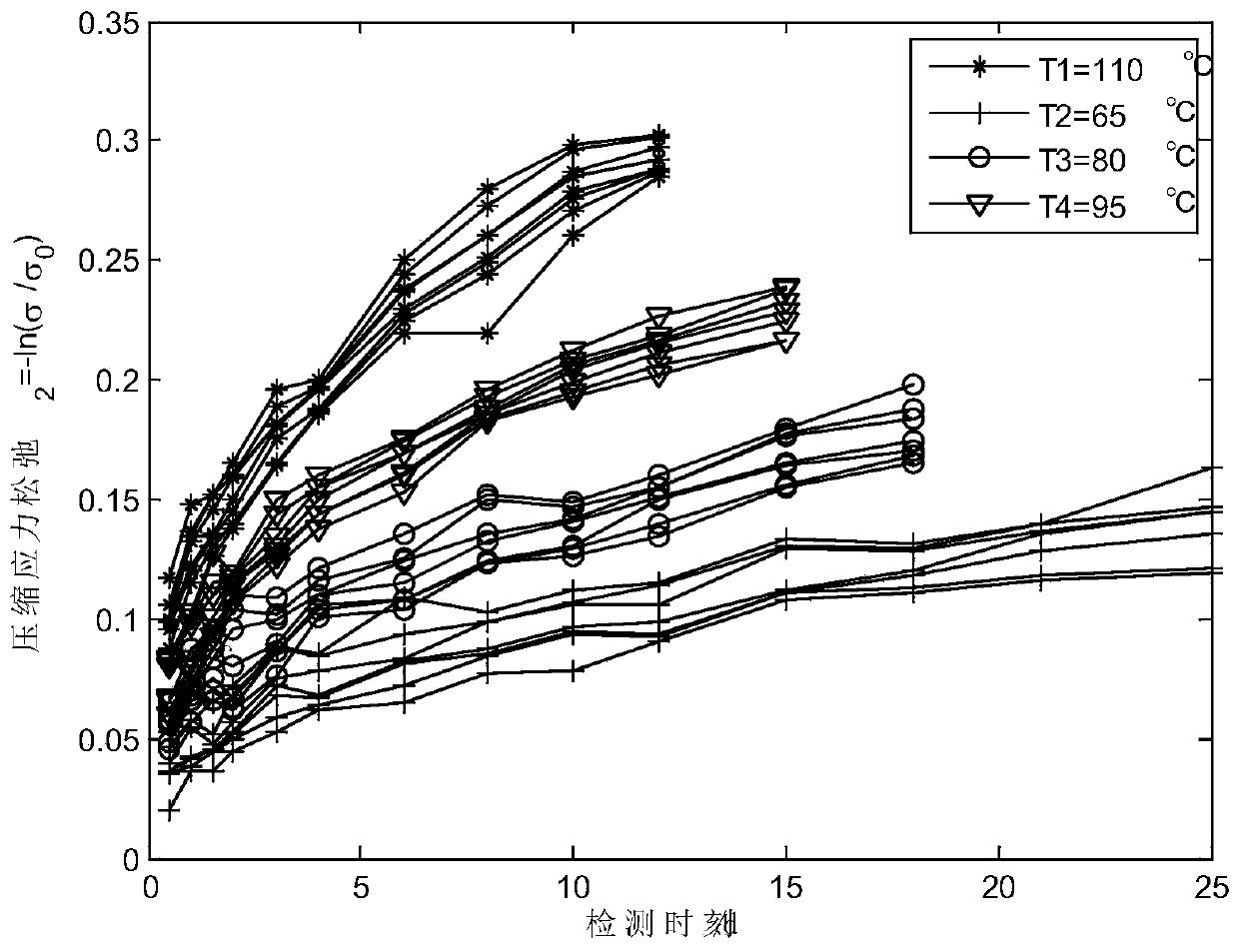

[0105] Taking the nitrile rubber O-ring as the research object, a constant stress accelerated degradation test is carried out, and the collected degradation data is recorded as X ik (t j / S p ), where i=1,2,…,m p , j=1,2,...n p , p=1,2,...,P; k=2 means that there are two performance parameters, namely compression set ε and compression stress relaxation rate σ / σ 0 , P=4 means that there are four accelerated stress levels, T 1 =65℃, T 12 =80℃, T 3 =95℃, T 4 =110℃, m p =8 means that 8 samples were put into the four temperature stress levels respectively, n 1 =14,n 2 =12,n 3 =11,n 4 = 10 means the number of measurements under the four stresses, and the test censored test is respectively t 1 =25d,t 2 =18d,t 3 =15d,t 4 = 12d, and the number of tests under each temperature stress is different;

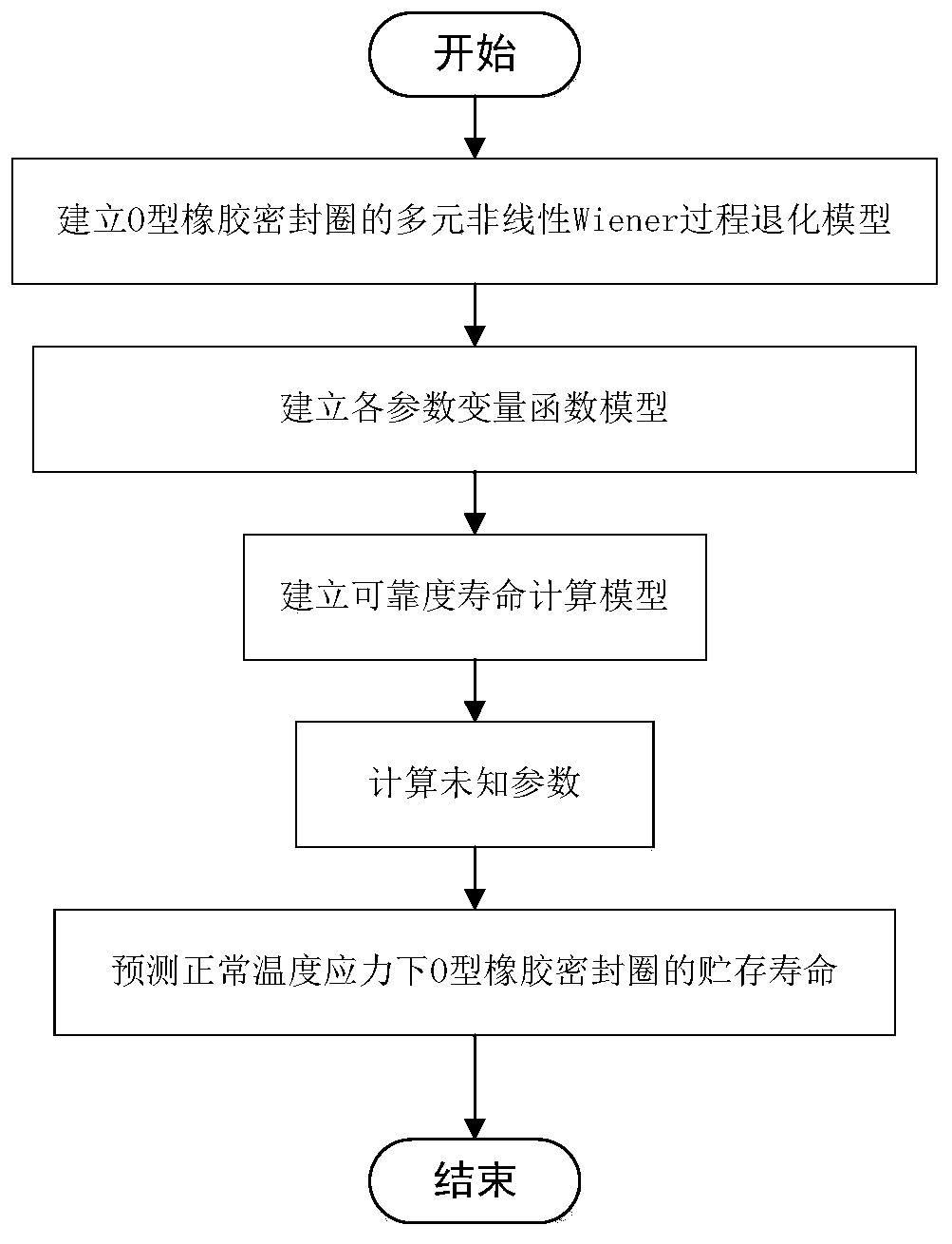

[0106] Step 1. Establish the multivariate nonlinear Wiener process degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com