Method for producing waterproof fiber product

A technology of fiber products and manufacturing methods, which is applied in the field of manufacturing waterproof fiber products, can solve the problems of large environmental load, high price, and difficult to decompose, and achieve the effects of excellent cost, soft touch, and less worry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0174] The present invention will be further described below, but the present invention is not limited by these examples.

[0175]

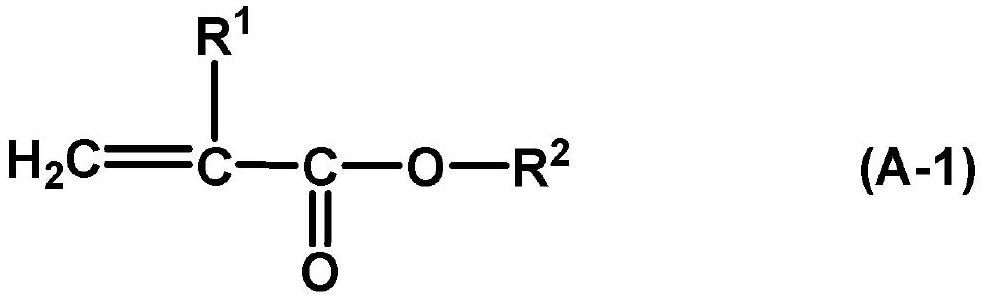

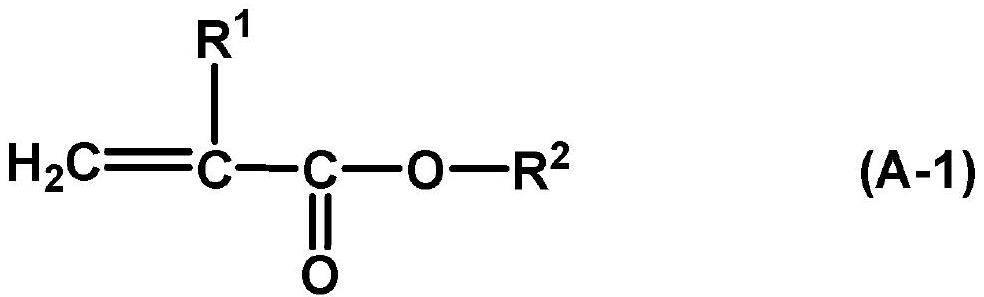

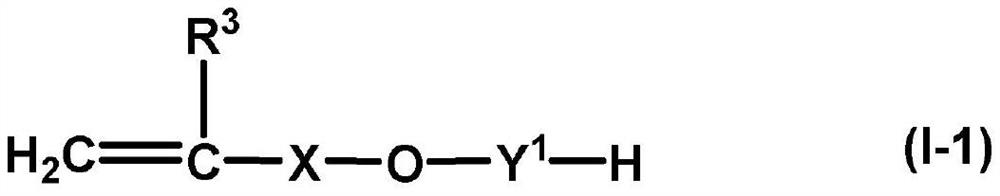

[0176] The mixture having the composition shown in Tables 1 and 2 (the numerical representation (g)) is polymerized by the procedure shown in the following, and the polymer dispersion is obtained.

Synthetic example 1

[0178] Acrylic 20g of acrylate is charged in a 500 ml flask, a PD-430 (manufacturing, polyoxyalkylene ether, HLB = 14.4) (manufactured by Huang Co., Ltd., manufacturing, gauge Oxide oxide ether, HLB = 12.6) 2g, hydrochloromethyl amine hydrochloride 3g, tropopropylene glycol 25g and water 207.70 g, mixed at 45 ° C, and mixed. The mixture is irradiated with ultrasonic waves to disperse all monomers. Next, azo dithis (isobutyl) dihydrochloride was added to the mixture, and the radical polymer was polymerized at 60 ° C for 6 hours under a nitrogen atmosphere, and the polymer was obtained as a non-fluorine water repellent. The concentration of 21% by mass of non-fluorine-based acrylic polymer dispersion.

Synthetic example 2~10

[0180] In addition to the materials described in Tables 1 and 2, polymerization was carried out in the same manner as in Example 1, and as the non-fluorine water repellent, the polymer concentration of the polymer concentration shown in Tables 1 and 2 was obtained. Dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| zeta potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com