Method for monitoring and operating multiple melt spinning locations and melt spinning apparatus having multiple melt spinning locations

A melt spinning, operator's technology, applied in the direction of melt spinning, textile and paper making, complete sets of equipment for producing artificial threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

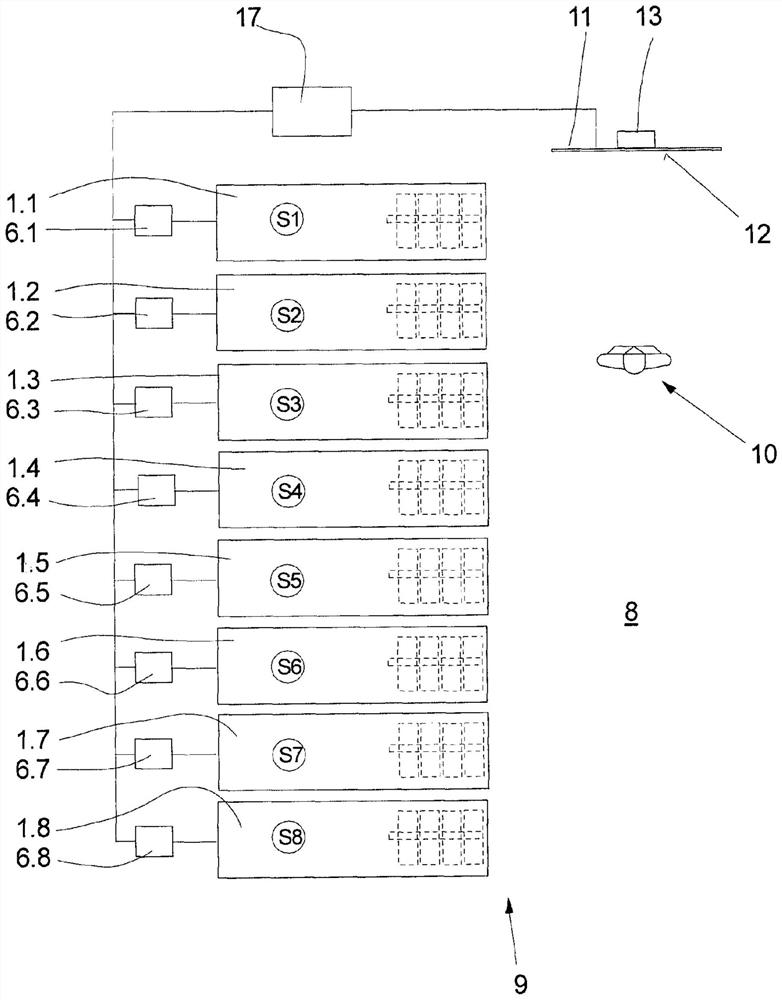

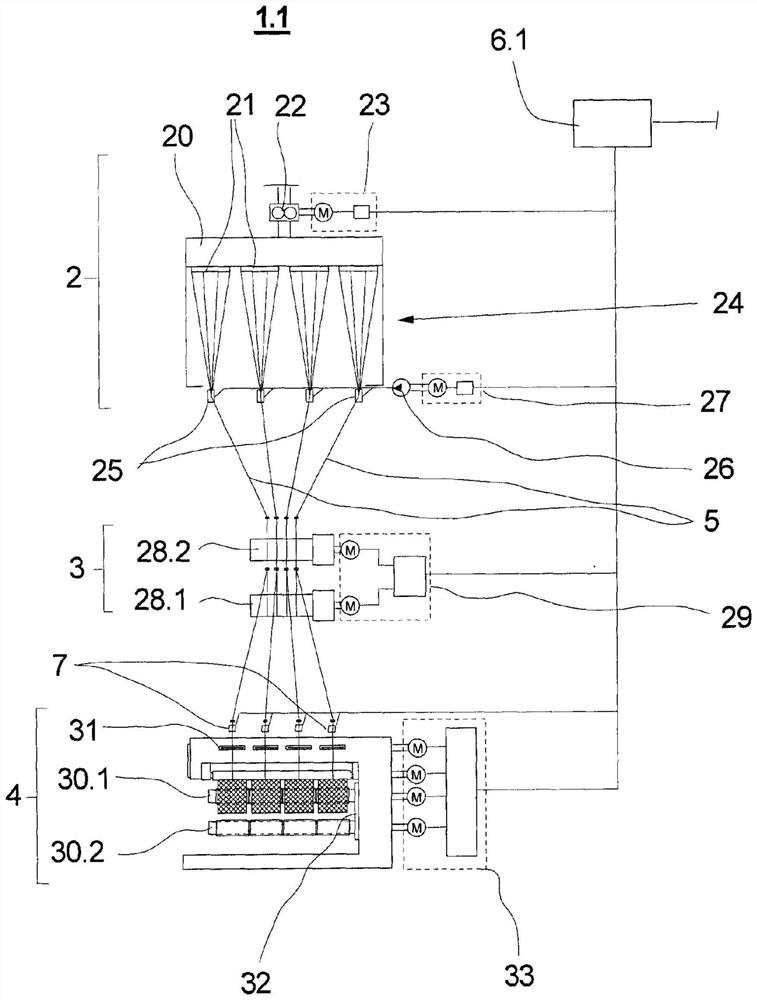

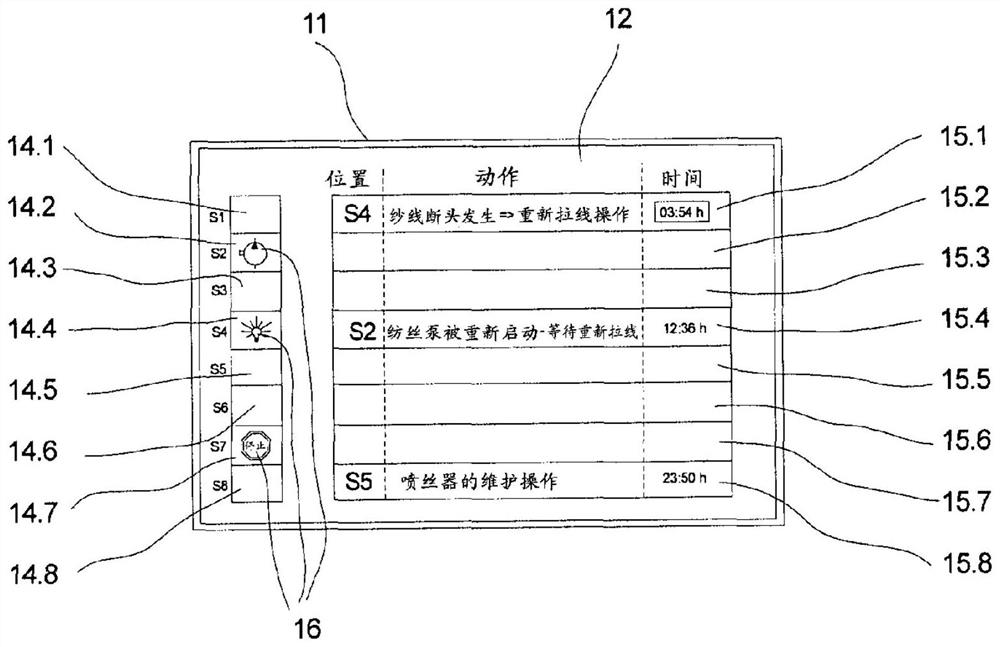

[0032] A first exemplary embodiment of the melt spinning apparatus is in figure 1 It is schematically shown in the top view in . The melt spinning device has a plurality of melt spinning positions 1.1 to 1.8. The melt spinning positions 1.1 to 1.8 have the same configuration and will be explained in more detail using the example of spinning position 1.1. For this purpose, in figure 2 A side view of the melt spinning position 1.1 is schematically shown in .

[0033] Such as figure 2 As shown in the illustration in , the melt spinning station 1.1 has a spinning device 2, a godet device 3 and a winding device 4, the former being held in a vertical arrangement.

[0034] The spinning device 2 includes a spinning beam 20 on the underside of which a plurality of spinning nozzles 21 are arranged. In this exemplary embodiment of the melt spinning position 1.1, a total of four spinning nozzles 21 are arranged in an exemplary manner on the underside of the spinning beam 20. Thus,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com