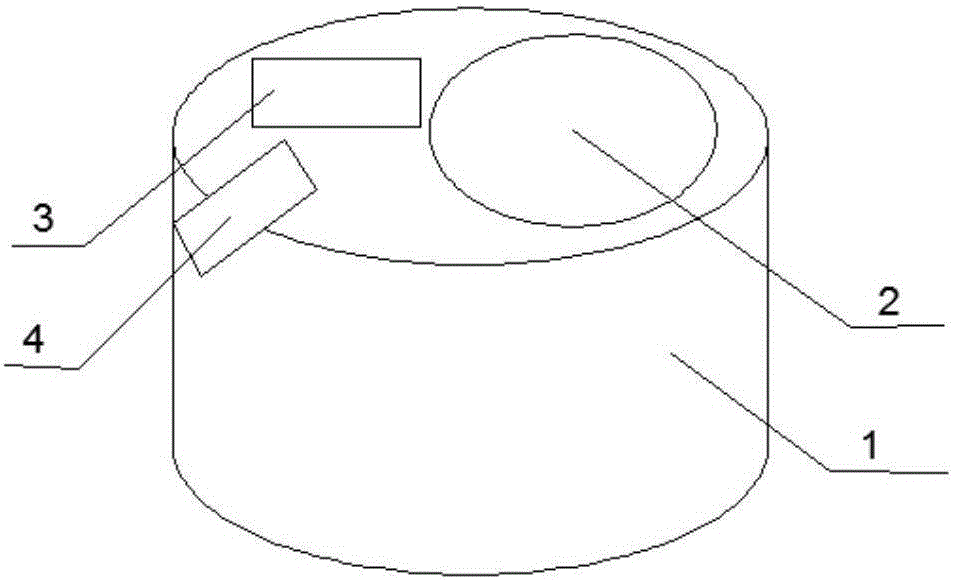

Inkstone and preparation method thereof

An inkstone table and inkstone core technology, applied in the field of inkstone table and its preparation, can solve the problems of easy damage to the clay inkstone body, failure to achieve the design effect, easy expansion and deformation of the mud material, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

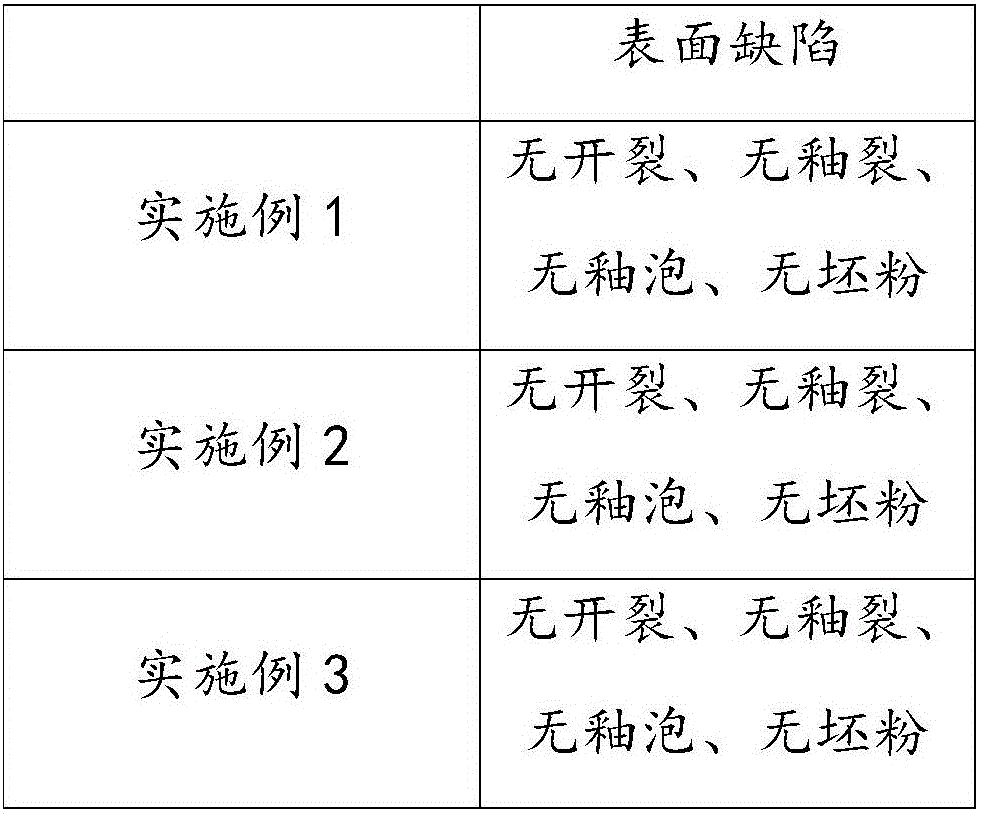

Embodiment 1

[0081] 1. Gypsum mold making: It usually takes 1 day to make the original tire mold with gypsum, depending on the complexity of the inkstone.

[0082] 2. Cloth wrapping: To make the general shape of the base of the inkstone, wrap the linen cloth on the surface of the original gypsum tire mold to shape the shape of the vessel. Fine tile ash, raw lacquer and binder (polyvinyl alcohol) are mixed in a weight ratio of 5:1:0.5, coated on the linen cloth and stuck to the surface of the carcass, dried in the shade, then repeatedly wrapped in cloth, scraped, and dried in the shade (at a humidity of 70%) -80%, placed in an environment with a temperature of 25-30°C for two days) step 4 times, until the carcass reaches a certain thickness and firmness.

[0083] 3. Remove gypsum: Break the gypsum into pieces.

[0084] 4. Take the shape: use a knife or tool to cut and cut the excess corners.

[0085] 5. Scraping and polishing: The paste made by mixing raw lacquer with tile ash (5:1 in wei...

Embodiment 2

[0097] 1. Gypsum mold making: It usually takes 1 day to make the original tire mold with gypsum, depending on the complexity of the inkstone.

[0098] 2. Cloth wrapping: To make the general shape of the base of the inkstone, wrap the linen cloth on the surface of the original gypsum tire mold to shape the shape of the vessel. Fine tile ash, raw lacquer and binder (carboxymethyl cellulose) are mixed in a weight ratio of 5:3:0.1, coated on the linen cloth and adhered to the surface of the carcass, dried in the shade, and then repeatedly wrapped in cloth, scraped, and dried in the shade (at humidity 50%-60%, placed in an environment with a temperature of 22-25°C for two days) step 3 times, until the carcass reaches a certain thickness and firmness.

[0099] 3. Remove gypsum: Break the gypsum into pieces.

[0100] 4. Take the shape: use a knife or tool to cut and cut the excess corners.

[0101] 5. Scraping and polishing: The paste made by mixing raw lacquer with tile ash (5:1 i...

Embodiment 3

[0112] 1. Gypsum mold making: It usually takes 1 day to make the original tire mold with gypsum, depending on the complexity of the inkstone.

[0113] 2. Cloth wrapping: To make the general shape of the base of the inkstone, wrap the linen cloth on the surface of the original gypsum tire mold to shape the shape of the vessel. Fine tile ash, raw lacquer and binder (polyvinyl alcohol and carboxymethyl cellulose are mixed together) in a weight ratio of 5:2:0.3, spread on the linen cloth and stick to the surface of the carcass, dry in the shade, and then repeat the wrapping and scraping. Ash, dry in the shade (placed in an environment with a humidity of 70%-80% and a temperature of 25-30°C for two days) 4 times until the carcass reaches a certain thickness and firmness.

[0114] 3. Remove gypsum: Break the gypsum into pieces.

[0115] 4. Take the shape: use a knife or tool to cut and cut the excess corners.

[0116] 5. Scraping and polishing: The paste made by mixing raw lacquer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com