Energy recovering flow control valves

A technology for controlling valves and fluid flow, which is applied in the direction of valve energy absorption devices, valve lifts, valve details, etc. It can solve the problems of local velocity increase, fluid average velocity decrease, and supply, etc., to reduce local velocity Peaking, reduced risk of cavitation, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

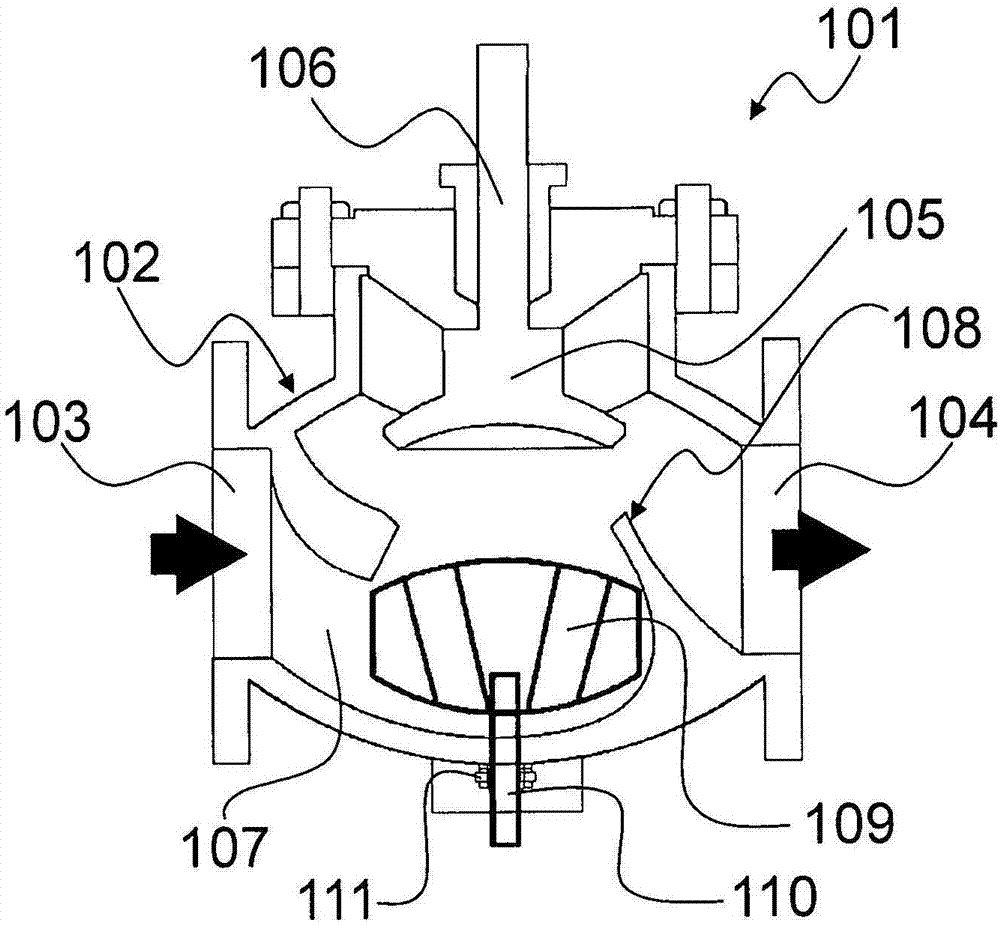

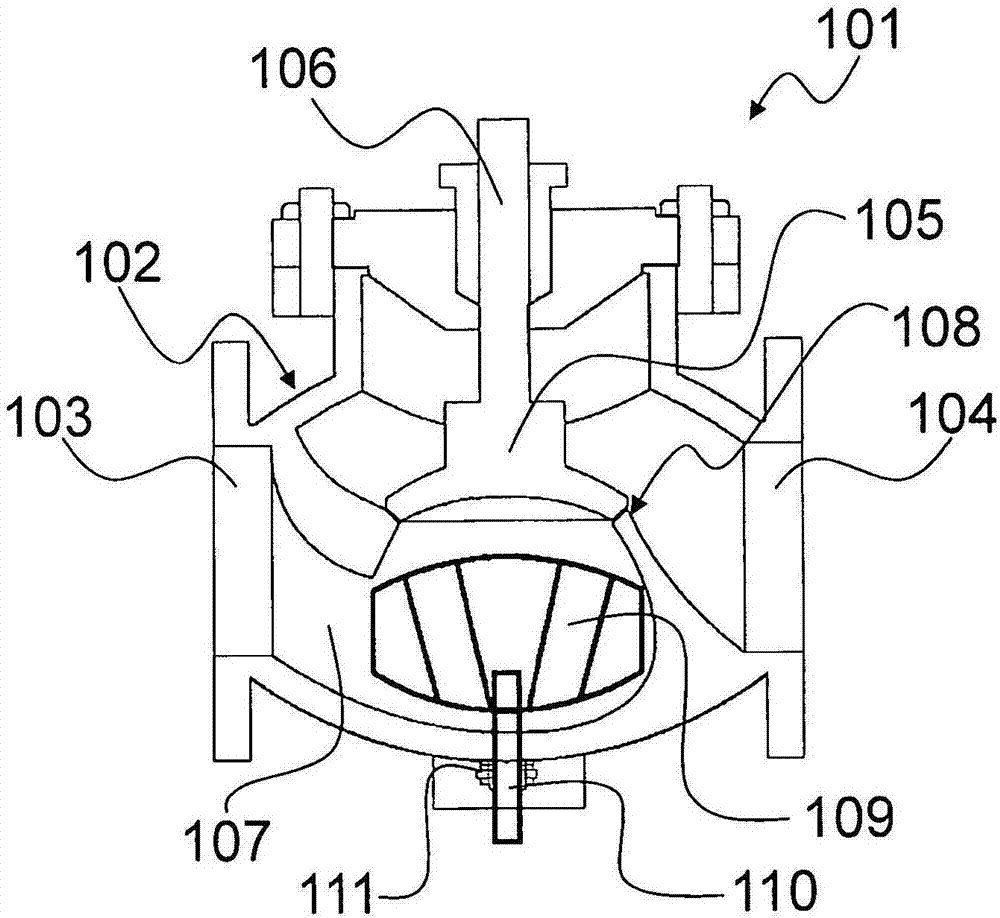

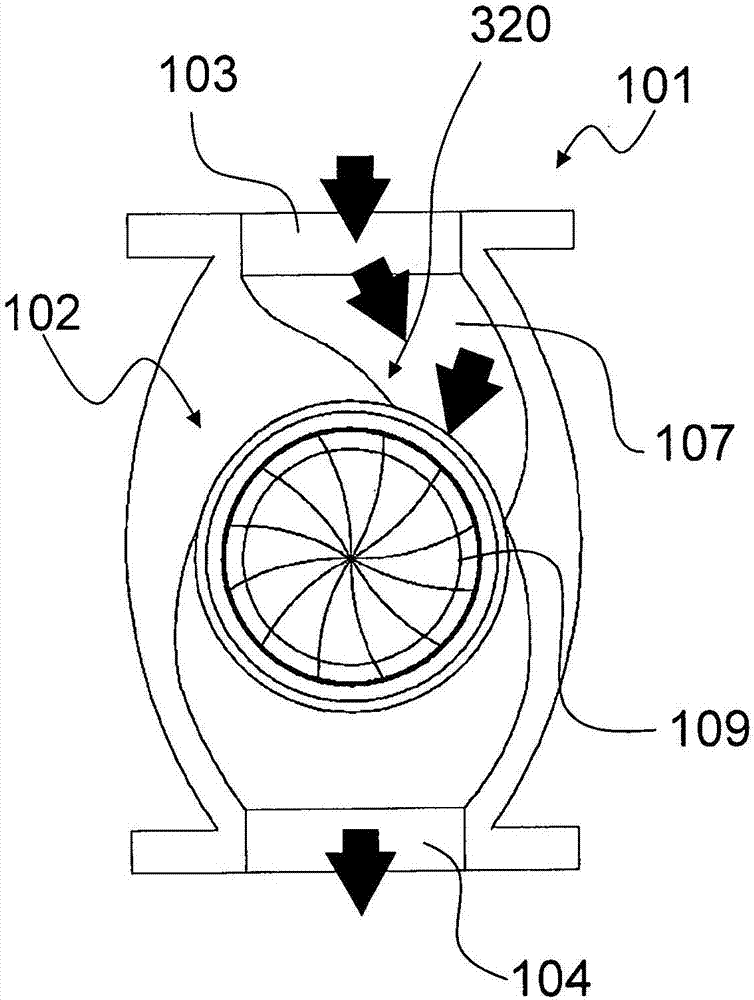

[0044] figure 1 A schematic diagram of one embodiment of a control valve 101 is shown, which is of the "ball" type.

[0045]Valve 101 includes a valve body 102 having an inlet 103 and an outlet 104 that allow fluid to flow through valve 101 in the direction indicated by the thick arrow.

[0046] In operating conditions, the valve 101 may be mounted to the piping of the pressurized system. Valve 101 also includes an occluder 105 inserted into valve body 102, and an actuation rod 106 configured to reversibly translate occluder 105 within the valve body.

[0047] In the illustrated embodiment, the actuating rod 106 may be manually operated, for example by means of a screw-type mechanism and a knob (not shown); however, other solutions are possible for the actuator system. Possible, for example mechanical or pneumatic or hydraulic or electric or electromechanical.

[0048] The occluder 105 is configured to be in the first position (see figure 1 ) and a second position in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com