Piston for syringes and syringes

A technology for syringes and pistons, applied in the field of syringes, can solve problems such as missed hearing and weak sound signals, and achieve reliable pushing and automatic centering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

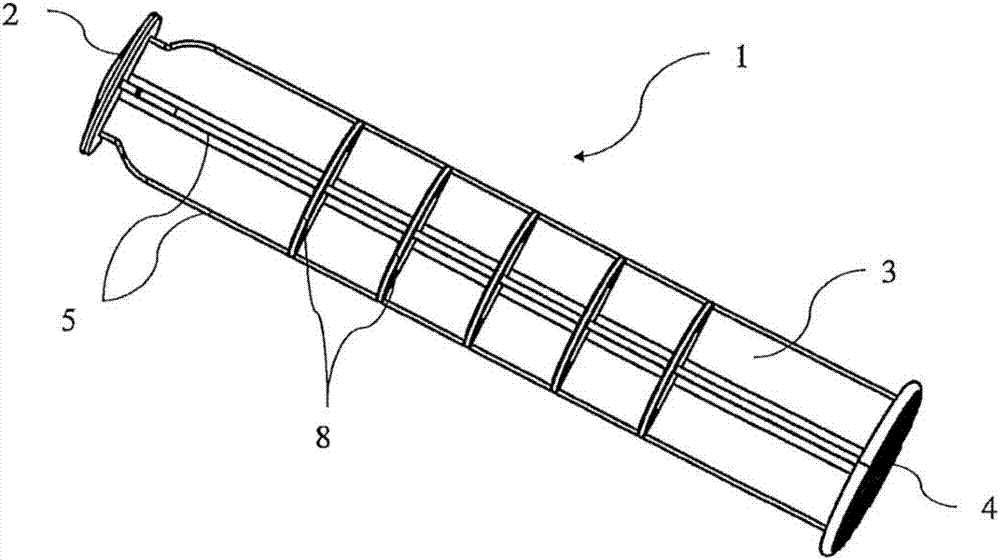

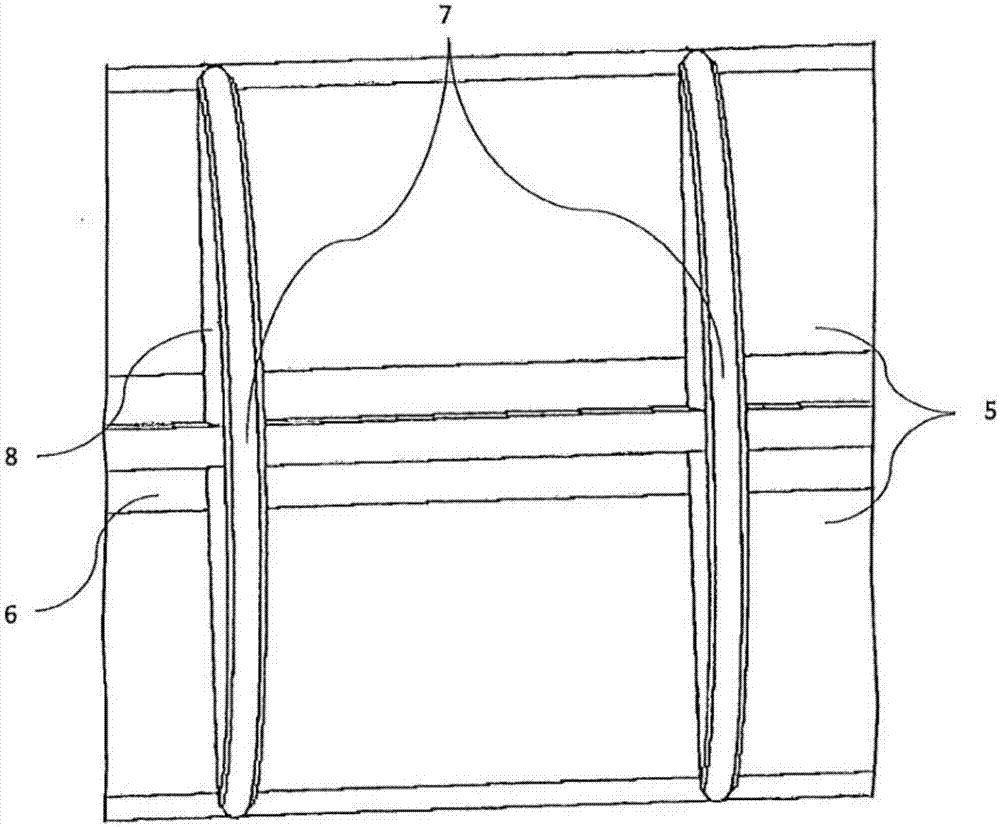

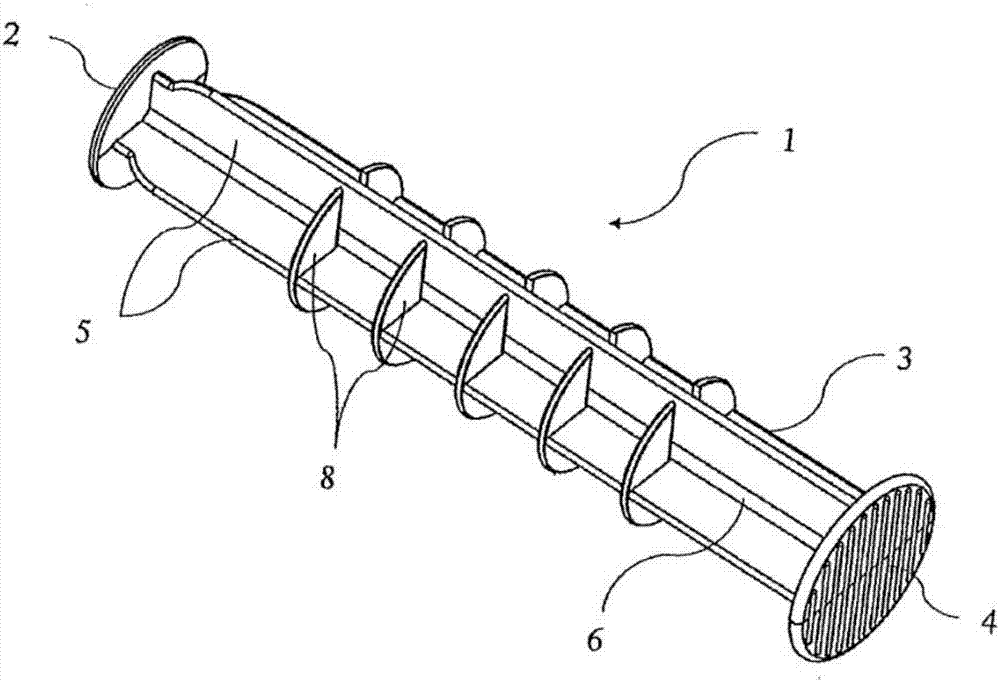

[0039] figure 1 and figure 2 A first embodiment of the piston 1 is concerned. In this case, the piston 1 has a piston rod 3 , a piston head 2 is located at one end of the piston rod, and an actuating section 4 is located at the other end of the piston rod. The piston rod 3 consists of four pairs of vertically standing axial webs 5 . These axial webs 5 lead into a common central intersection or core section 6 that accommodates the longitudinal axis. figure 2 In the enlarged view, two of the balancing rod bodies 8 arranged in parallel on the piston rod 3 and extending in the circumferential direction are shown. The balancing rod body 8 has a completely surrounding disk-like or plate-like basic shape and has a likewise completely surrounding excitation edge 7 on the radially outwardly directed edge. The radial distance of the balancing rod body 8 from the longitudinal axis 12 is greater here than the radial distance of the axial web 5 from the longitudinal axis 12 of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com