Double-station upsetting female die shifting device and using method

A technology of shifting device and double station, which is applied in the field of steel pipe upsetting, can solve the problems of difficulty in production, shifting of double station die and high cost, saving investment cost, reliable shifting of die, and reducing production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

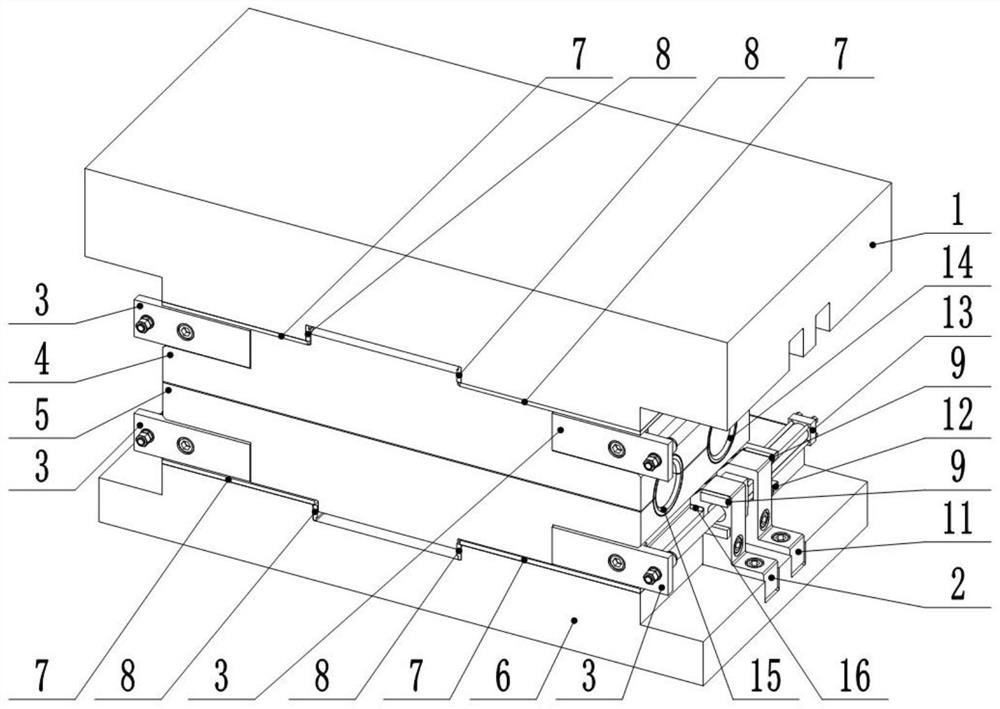

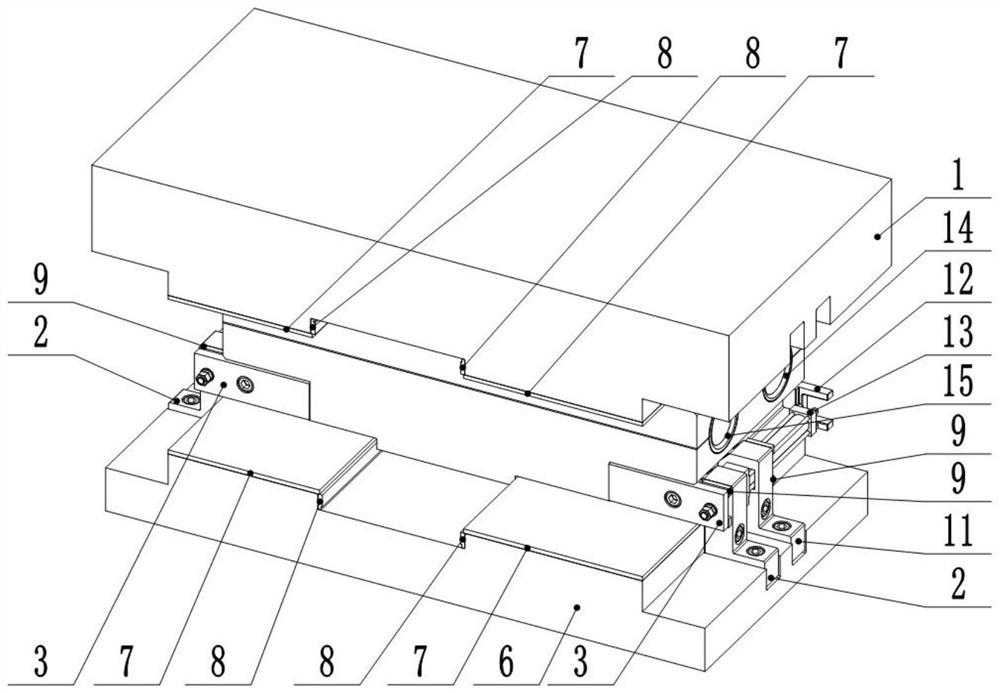

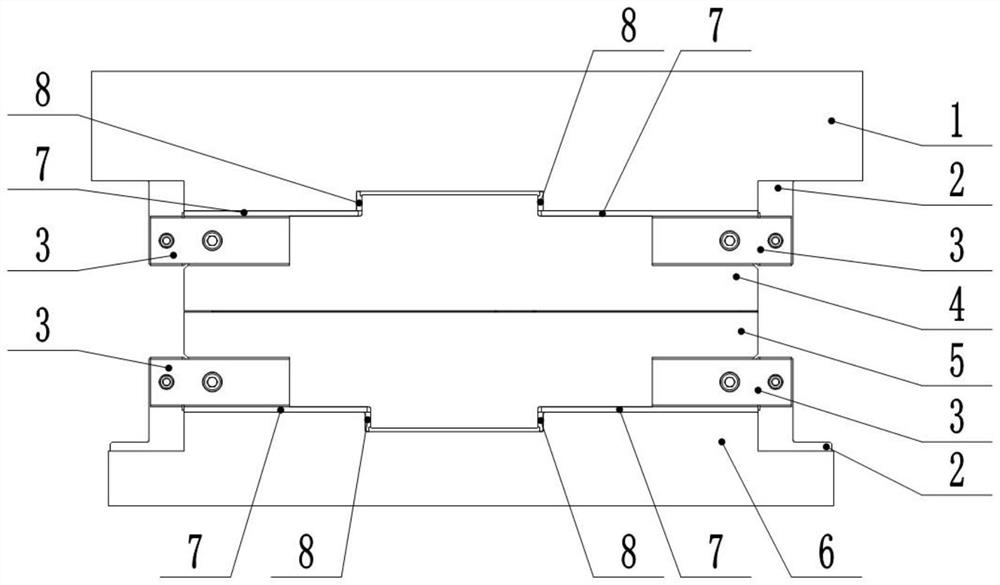

[0025] This embodiment relates to a double-station upsetting die displacement device, such as Figure 1-Figure 6 Shown: including: lifting slider 1, front limit block 2, front moving block 3, upper die seat 4, lower die seat 5, worktable 6, rear limit block 11, rear moving block 12.

[0026] Further, the lifting slider 1 is connected to the upper die base 4 through the front limit block 2 and the rear limit block 11; The lower die base 5 is connected.

[0027] Further, the upper concave mold base 4 and the lower concave mold base 5 are provided with a first concave mold 14 and a second concave mold 15 .

[0028] Further, limit pads (9) are provided on the front side of the front limit block 2 and the rear side of the rear limit block 11.

[0029] Further, an oil cylinder 13 is provided between the lifting slider 1 and the upper die base 4 ; an oil cylinder 13 is provided between the worktable 6 and the lower die base 5 , and the oil cylinder 13 is installed on the The rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com