Pull and / or push rod

A technology of pull rods and push rods, which is applied in belts/chains/gears, transmission devices, manufacturing tools, etc., and can solve problems such as threaded hollow rod skew and system blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

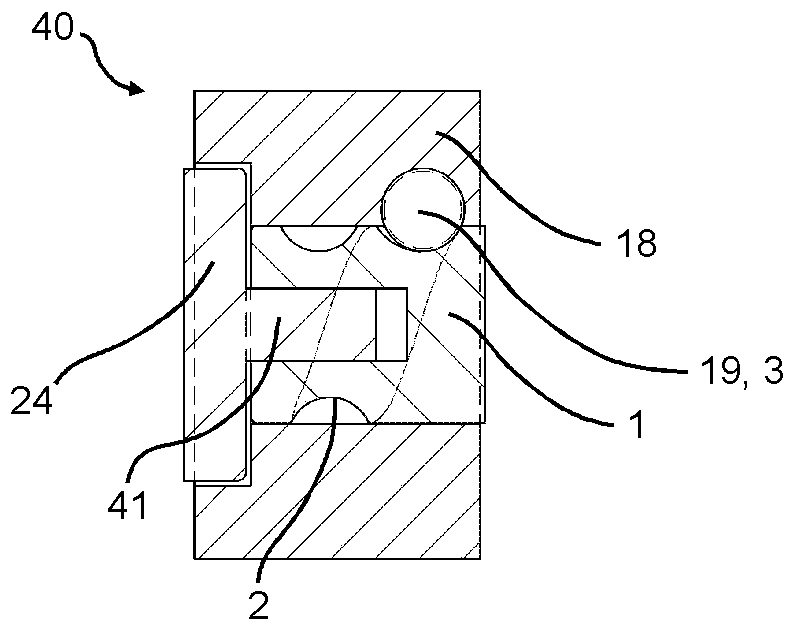

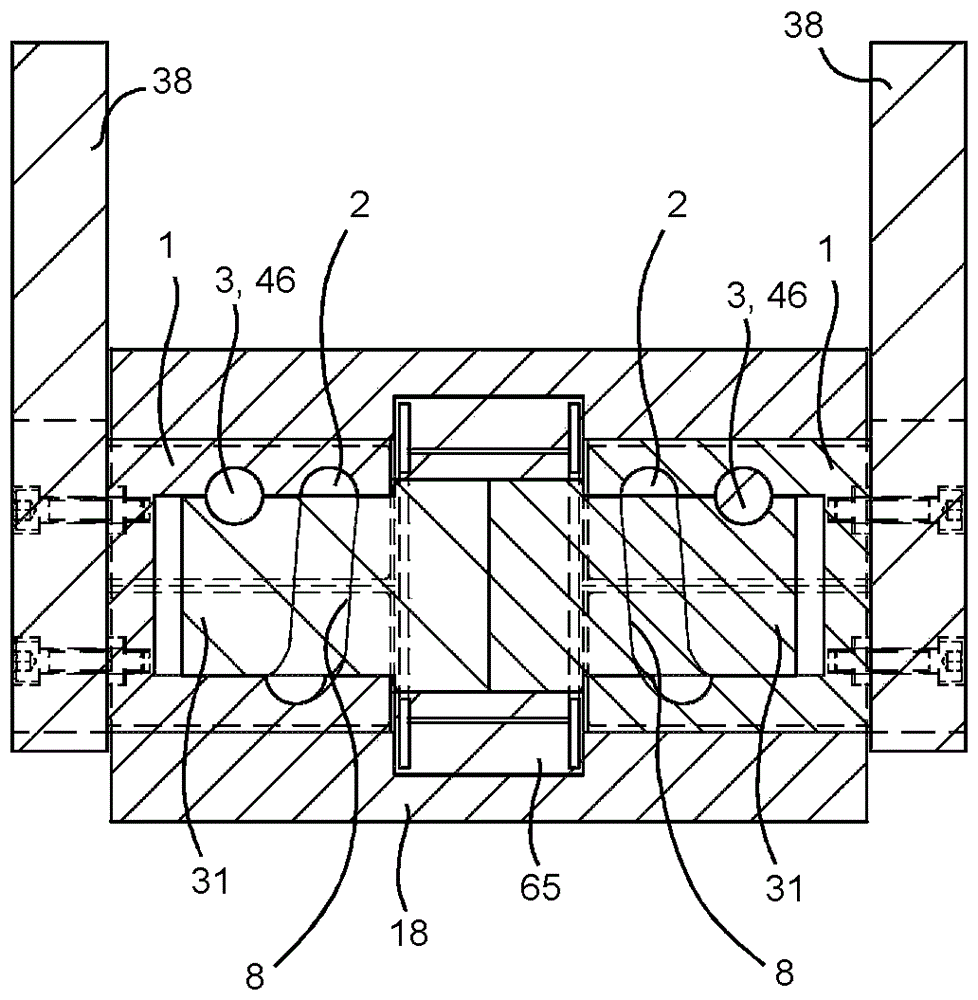

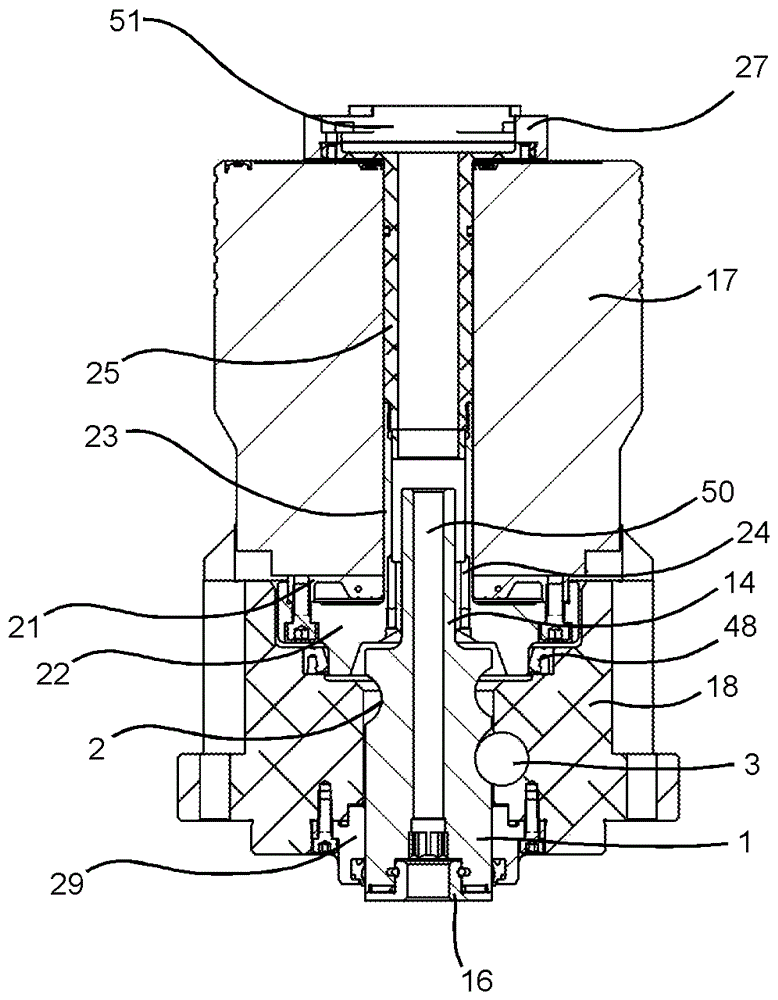

[0056] exist Figures 1a to 1e A draw rod and / or push rod 1 is shown in , which is displaceable along the rod longitudinal axis. The pull and / or push rod has a control curve 2 for guiding the control element 3 , which comprises an at least partially helical helix with one or more pitch sections 4 , 5 , 6 , 7 Section 8.

[0057] Furthermore, the control curve 2 comprises at least one free-running section 9 , 10 which is connected to the helical section 8 , extends substantially radially relative to the longitudinal axis of the rod, and is preferably arc-shaped. In the exemplary embodiment, exactly two free-travel sections 9 , 10 are provided, wherein the first free-travel section 9 is arranged at the first end of the spiral section 8 and wherein the second free-travel section 10 is arranged at a second end of the spiral section 8 opposite the first end. Preferably, the free-running sections 9 , 10 of the tie rod and / or push rod 1 extend radially relative to the rod longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com