Uniaxial loaded coal ultrasonic velocity testing system device and experimental method thereof

A testing device and ultrasonic technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, processing response signals of detection, and instruments, etc., can solve the problems of poor comprehensiveness of mechanical testing performance of testing work surfaces, insufficient general-purpose testing equipment, and poor use flexibility. and other problems, to achieve the effects of high detection efficiency and detection accuracy, improved detection efficiency, and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

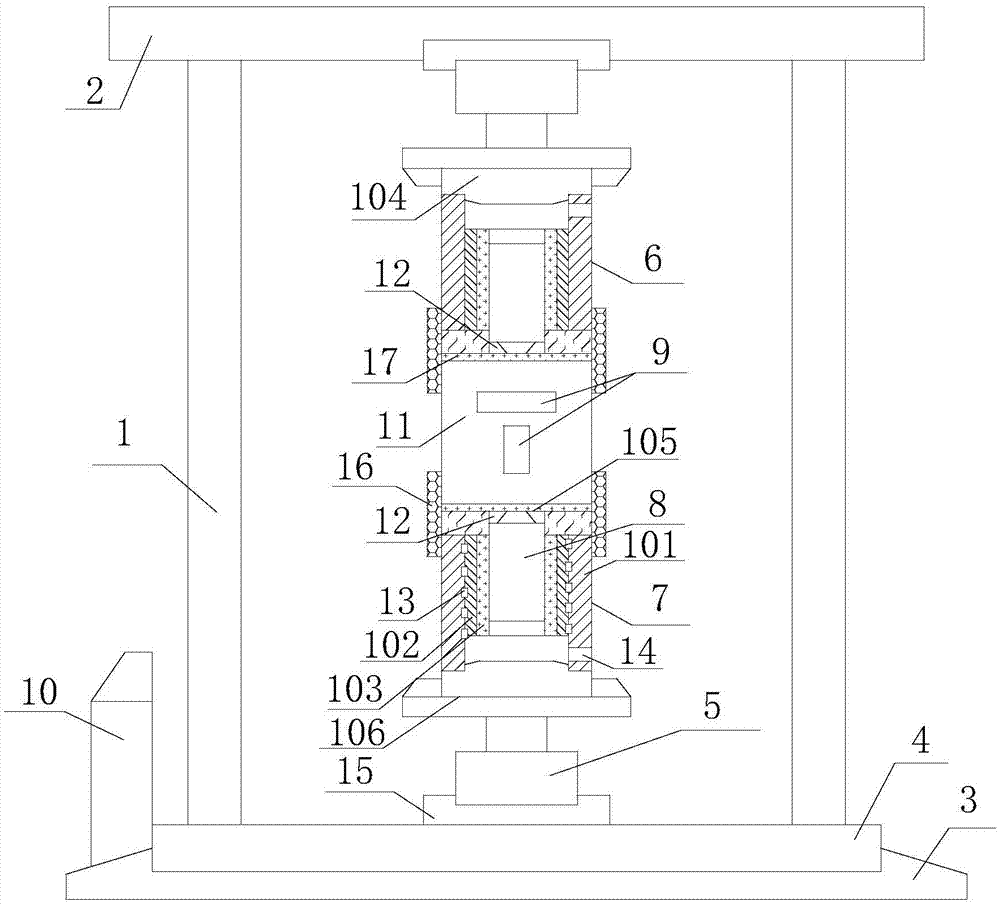

[0054] Such as figure 1 with 2 shown, as figure 1 As shown, a uniaxially loaded coal mass ultrasonic velocity test device includes a bearing column 1, a beam 2, a base 3, a workbench 4, a lifting drive mechanism 5, an upper detection body 6, a lower detection body 7, and an acoustic wave transducer 8 , the resistance strain gauge 9 and the control circuit 10, there are two load-bearing columns 1, which are symmetrically distributed on the center line of the base 3, and the two ends of the load-bearing column 1 are respectively connected with the crossbeam 2 and the base 3 perpendicularly to each other to form a rectangular frame structure, and the workbench 4 has a total Two, respectively installed on the upper surface of the base 3 and the lower surface of the beam 2 through the lifting drive mechanism 5, and the two worktables 4 are coaxially distributed with each other, and the upper detection body 6 and the lower detection body 7 are respectively installed on the base 3 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com