Heat recovery fresh air equipment

A technology of heat recovery and heat recovery core, which is applied in the field of air conditioning, can solve the problems of large unit size, unpopularity, selection of filters and heat recovery cores that cannot be too small, and reduce functional components and indoor space Small, easy interior design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

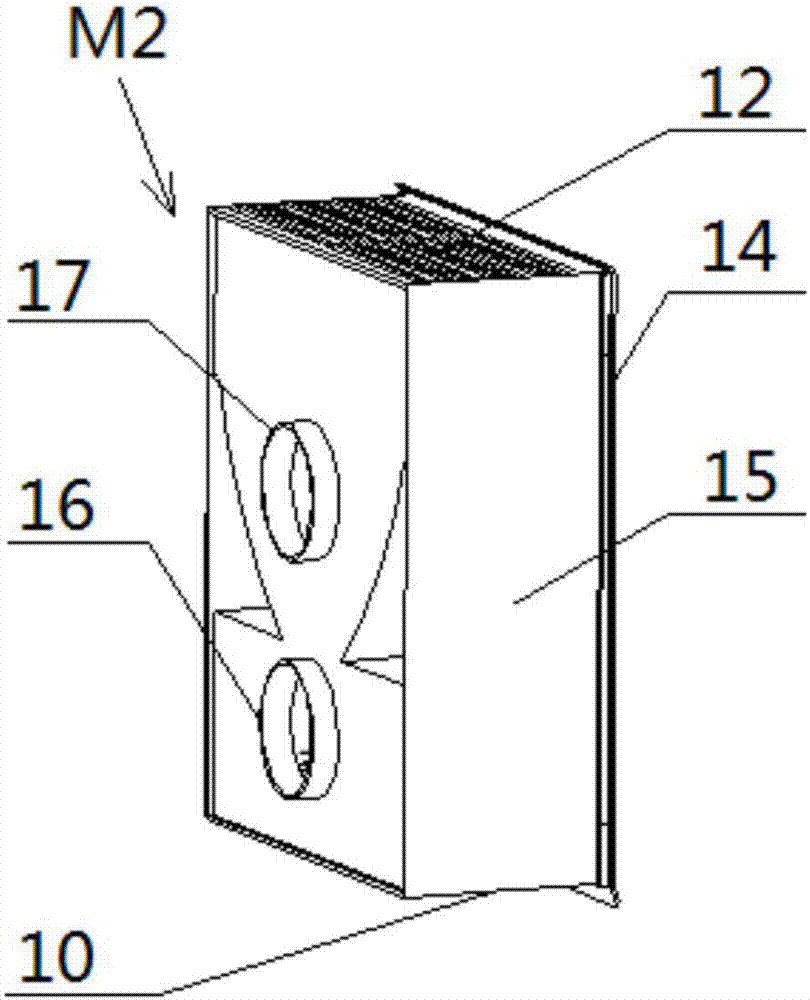

[0027] Such as figure 1 Shown is a schematic diagram of the internal structure of an embodiment of the heat recovery fresh air equipment of the present invention. In this embodiment, the heat recovery fresh air equipment includes: an indoor unit M2 , an outdoor unit M1 and a heat recovery core 2 . The indoor unit M2 includes a fresh air cavity and an exhaust air passage which are not connected inside. The outdoor unit M1 includes an exhaust cavity and a fresh air channel that are not connected inside. The fresh air cavity of the indoor unit M2 is connected to the fresh air channel of the outdoor unit M1, the exhaust channel of the indoor unit M2 is connected to the exhaust cavity of the outdoor unit M1, and the heat recovery core 2 is installed between the fresh air channel and the exhaust cavity of the outdoor unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com