A method for color correction of wedding fabric

A technology for fabrics and wedding celebrations, which is applied in dyeing, textiles and papermaking. It can solve the problems of fluffing and pilling on the surface of fabrics, the failure of softener stripping, and the reduction of color fastness, so as to achieve smooth silk surface, improve color fastness, The effect of color fastness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

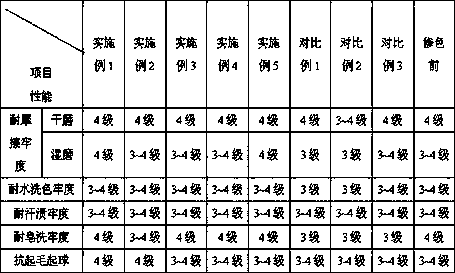

Examples

Embodiment 1

[0026] In this embodiment, color-repairing polyester-cotton jacquard bright red, 100d*32s / 2 combed cotton, 173*60;

[0027] Its method is as follows:

[0028] Formula: peeling softener additives: wax remover 2g / l, silicon spot remover 2g / l, acetic acid 1g / l;

[0029] Padding finishing agent for four-roller finishing machine: color fixing agent ZJ-700 3g / l, acetic acid 0.5g / l;

[0030] Softener formula: softener 3165: 15g / l, smoothing agent 7200: 5g / l, acetic acid 0.5g / l;

[0031] 1) Dry cloth on the machine: drive and run one;

[0032] 2) Washing: 2 washes at 40°C, drain the waste water, and remove the aggregates with a filter;

[0033] 3) Water washing: 2 washes at 60°C, drain the waste water, and remove the aggregates with a filter;

[0034] 4) Washing: 2 washes at 80°C, drain the waste water, and remove the aggregates with a filter;

[0035] 5) Water washing: 2 washes at 90°C, drain the waste water, and remove the aggregates with a filter;

[0036] 6) Strip the soften...

Embodiment 2

[0047] In this embodiment, the color-correcting fabric is polyester viscose jacquard scarlet, 75d*120D, 173*120;

[0048] Its method is as follows:

[0049] Formula: softener formula: wax remover 1.5g / l, silicon spot remover 1.5g / l, acetic acid 0.5g / l;

[0050] Padding finishing agent for four-roller finishing machine: color fixing agent ZJ-700 2.5g / l, acetic acid 0.2g / l;

[0051] Softener formula: Shanghai Daxiang amino silicone oil 141: 13g / l, slippery finishing agent 6660: 4g / l, acetic acid 0.5g / l;

[0052] 1) Dry cloth on the machine: drive and run one;

[0053] 2) Washing: Wash once at 41°C, drain the waste water, and remove the aggregates with a filter;

[0054] 3) Water washing: wash with water at 59°C for 1 time, drain the waste water, and remove the aggregates with a filter;

[0055] 4) Washing: 2 washes at 80°C, drain the waste water, and remove the aggregates with a filter;

[0056] 5) Water washing: wash 2 times with water at 88°C, drain the waste water, and rem...

Embodiment 3

[0068] In this embodiment, the color-correcting fabric is polyester viscose jacquard scarlet, 75d*120D, 173*120;

[0069] Its method is as follows:

[0070] Formula: softener formula: wax remover 2.5g / l, silicon stain remover 2.5g / l, acetic acid 1.5g / l

[0071] Padding finishing agent for four-roller finishing machine: color fixing agent ZJ-700 3.5g / l, acetic acid 0.8g / l;

[0072] Softener formula: softener 3165: 16g / l, smoothing agent 7200: 6g / l, acetic acid 0.5g / l;

[0073] 1) Dry cloth on the machine: drive and run one;

[0074] 2) Washing: Wash once at 41°C, drain the waste water, and remove the aggregates with a filter;

[0075] 3) Water washing: 2 washes at 61°C, drain the waste water, and remove the aggregates with a filter;

[0076] 4) Washing: 2 washes at 79°C, drain the waste water, and remove the aggregates with a filter;

[0077] 5) Water washing: 2 washes at 90°C, drain the waste water, and remove the aggregates with a filter;

[0078] 6) Strip the softener:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com