Fermented grain distilling device

A distillation device and technology of fermented grains, applied in the preparation of alcoholic beverages, etc., can solve the problems of reducing the yield of alcohol, reducing the concentration of fermented grains, and low purity, so as to ensure the taste of the wine, avoid sticking, and ensure the yield of alcohol Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

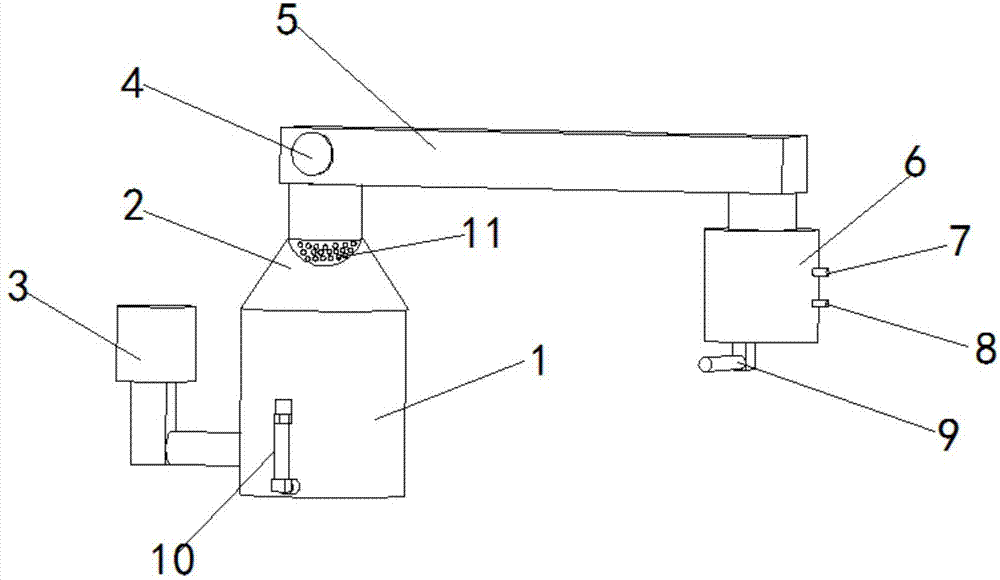

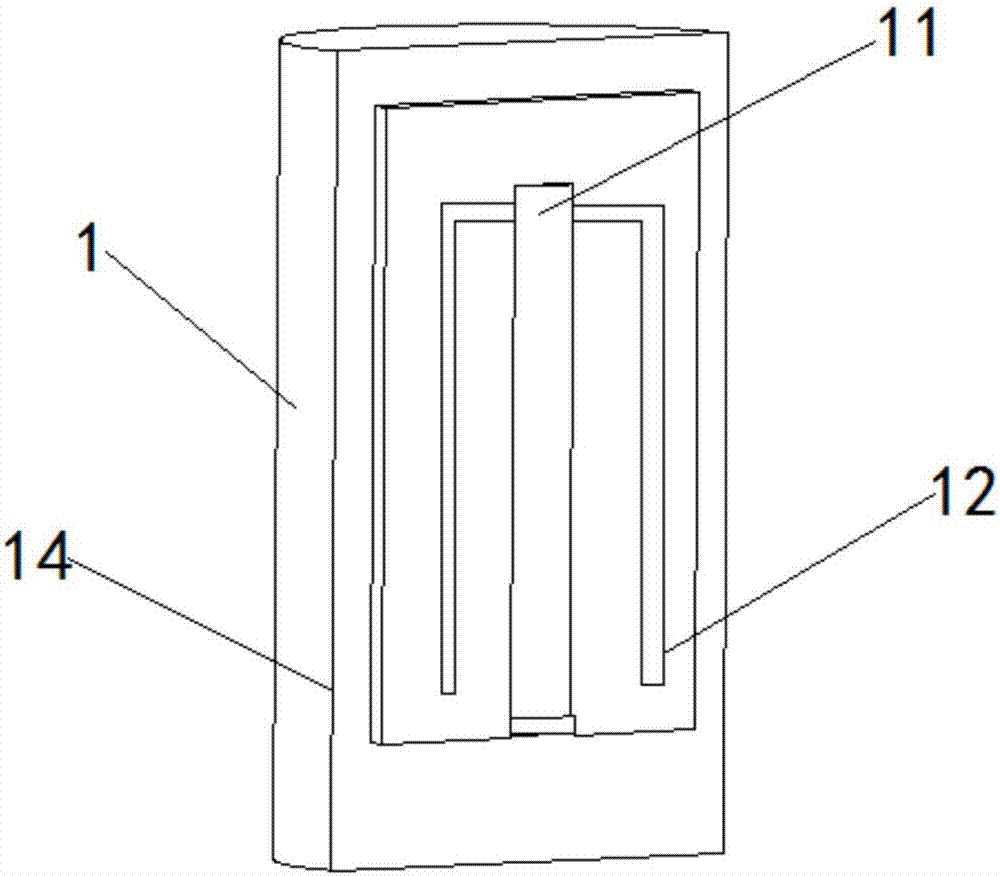

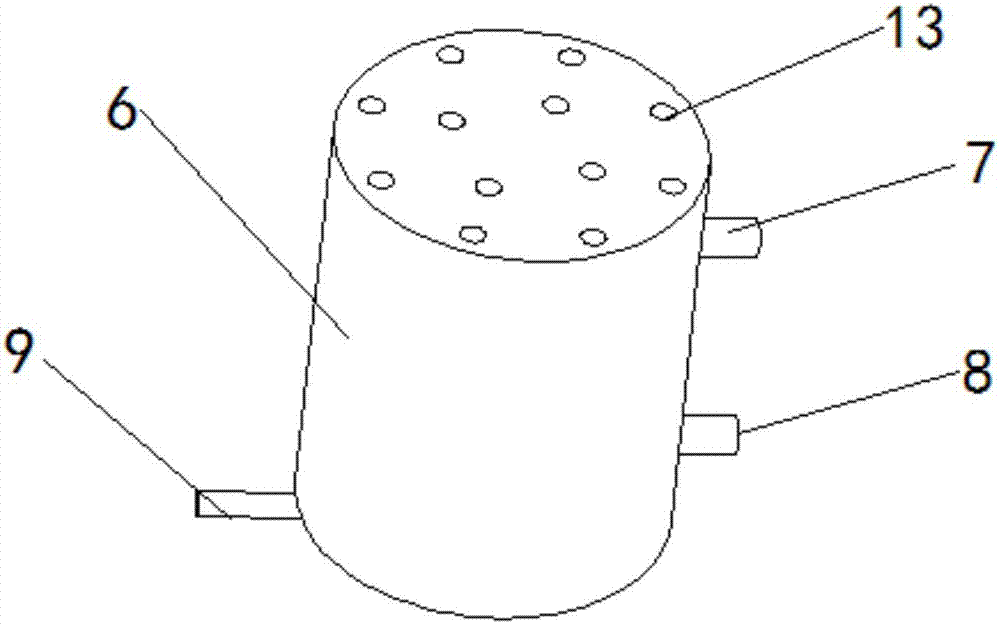

[0017] Embodiment 1: refer to figure 1 , a distillation device for fermented grains, comprising a double-layer barrel body 1, a 45° conical pot cover 2, a water inlet tank 3, a steam thermometer 4, a constant pressure air guide pipe 5, and a cooler 6, characterized in that: a double-layer barrel The top of the body 1 is a 45° conical pot cover 2, the 45° conical pot cover 2 is connected to the cooler 6 through a constant pressure air duct 5, and a wine outlet valve 9 is arranged under the cooler 6, and the left side of the double-layer barrel body 1 Connected to the water inlet tank 3, the heating layer at the bottom of the distillation device is connected to the hollow layer 14, and a circular interface is arranged at the bottom center of the double-layer barrel body 1, and the circular interface matches the steam pipe 11.

[0018] In this embodiment, combined with the principle of large-scale winery equipment and traditional sky pot equipment, a 45° conical pot cover 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com