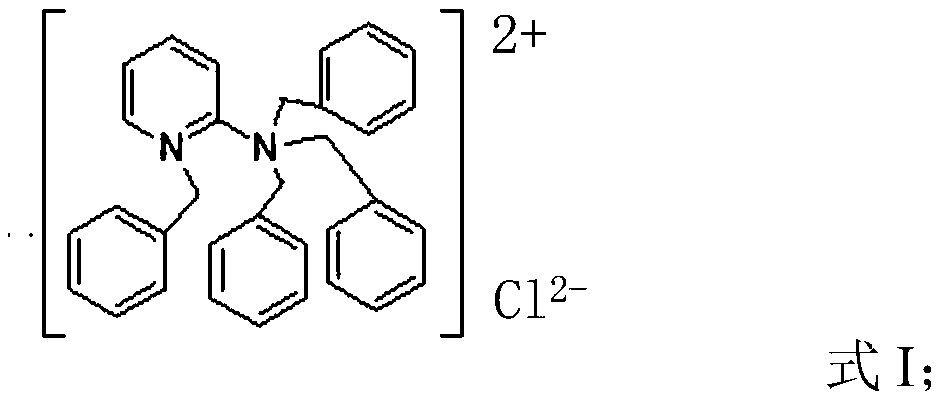

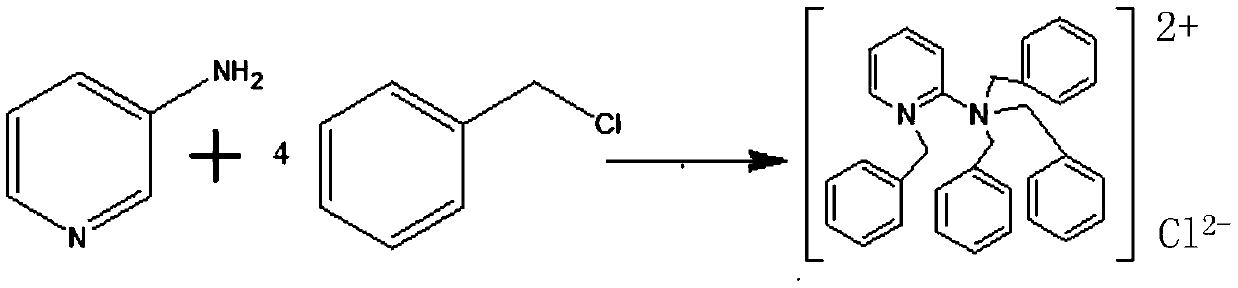

A high-temperature acidification corrosion inhibitor based on tribenzyl-(2-benzyl)pyridyl ammonium chloride

A technology of pyridyl ammonium chloride and acidification corrosion inhibitor, which is applied in the direction of organic chemistry, drilling composition, chemical instruments and methods, etc., can solve the problem of few varieties of acidification corrosion inhibitors, poor solubility and dispersibility, and insufficient performance Stability and other issues, to achieve a wide range of use, improve the quality of acidizing construction, and easy to use on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-temperature acidification corrosion inhibitor based on tribenzyl-(2-benzyl)pyridyl ammonium chloride, including 20 parts of corrosion inhibitor main agent, 1.0 part of potassium iodide, 0.5 part of antimony trioxide, 0.5 part of trichloride Antimony, 0.5 parts of propynyl alcohol, 0.5 parts of OP-10, 9 parts of triethanolamine, 1.0 parts of LAS, 5.0 parts of DMF, 5.0 parts of DMA, 57 parts of methanol.

[0030] When in use, the above-mentioned components are weighed and mixed evenly before being sent to the construction site for use or stored for later use.

Embodiment 2

[0032] A high-temperature acidification corrosion inhibitor based on tribenzyl-(2-benzyl)pyridyl ammonium chloride, including 22 parts of corrosion inhibitor main agent, 1.5 parts of potassium iodide, 0.5 parts of antimony trioxide, 0.5 parts of trichloride Antimony, 1.0 parts of propynyl alcohol, 0.5 parts of OP-10, 2.5 parts of triethanolamine, 0.5 parts of LAS, 3.0 parts of DMF, 3.0 parts of DMA, 64 parts of methanol.

[0033] When in use, the above-mentioned components are weighed and mixed evenly before being sent to the construction site for use or stored for later use.

Embodiment 3

[0035] A high-temperature acidification corrosion inhibitor based on tribenzyl-(2-benzyl)pyridyl ammonium chloride, including 25 parts of corrosion inhibitor main agent, 1.4 parts of potassium iodide, 0.5 part of antimony trioxide, 0.5 part of trichloride Antimony, 1.0 parts of propynyl alcohol, 0.5 parts of OP-10, 3.5 parts of triethanolamine, 1.0 parts of LAS, 2.0 parts of DMF, 5.0 parts of DMA, 59 parts of methanol.

[0036] When in use, the above-mentioned components are weighed and mixed evenly before being sent to the construction site for use or stored for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com