Graphene/black phosphorus nanosheet/sulfur-containing ionic liquid composite aerogel and preparation method thereof

A composite airgel and nanosheet technology, which is applied in the direction of aerosol preparation, sulfur compounds, phosphorus compounds, etc., can solve the problems of inconvenient recycling and reuse, and there are no research reports on black phosphorus aerogels, so as to facilitate recycling and recycling. Utilization, excellent stability, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

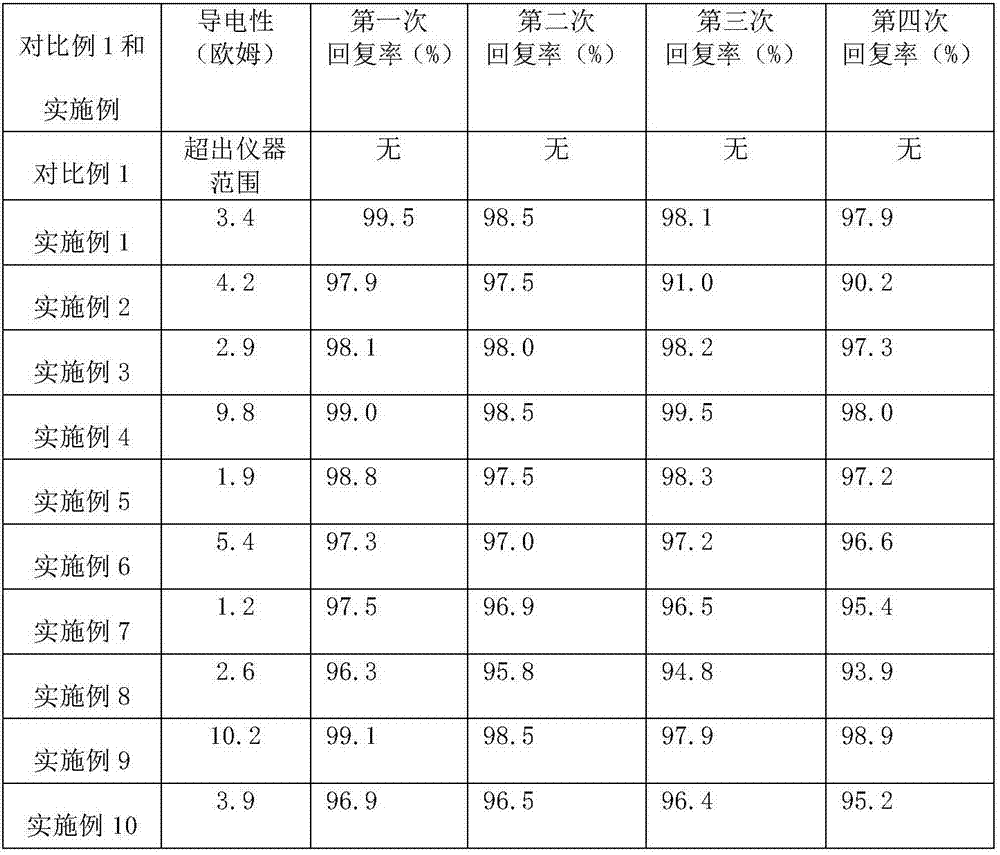

Embodiment 1

[0061] A preparation method of graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite airgel, comprising the following steps:

[0062] Step (1). Prepare uniform, stable black phosphorus nanosheet solution by liquid phase stripping method, and its specific steps are as follows:

[0063] 1-a): Di(butyl)methylsulfonium hexafluorophosphate (ie sulfur-containing ionic liquid) was vacuum-dried at 110°C for 48 hours;

[0064] 1-b): 25 mg of bulk black phosphorus and 500 mg of dried bis(butyl) methylsulfonium hexafluorophosphate (i.e. sulfur-containing ionic liquid) were added to an agate mortar in a mass ratio of 100:2000 for mechanical Grinding for 40 minutes; the mixture obtained after grinding was transferred to a round bottom flask, and 180 mL of N-methylpyrrolidone (NMP) was added to obtain the first mixed solution;

[0065] 1-c): The above-mentioned first mixed solution is subjected to probe ultrasonication for 3 hours, and the ultrasonic power is 600W; a...

Embodiment 2

[0105] A preparation method of graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite airgel, comprising the following steps:

[0106] Step (1). Prepare uniform, stable black phosphorus nanosheet solution by liquid phase stripping method, and its specific steps are as follows:

[0107]1-a): Di(butyl)methylsulfonium hexafluorophosphate (ie sulfur-containing ionic liquid) was vacuum-dried at 110°C for 48 hours;

[0108] 1-b): 25 mg of bulk black phosphorus and 25 mg of dried bis(butyl) methylsulfonium hexafluorophosphate (i.e. sulfur-containing ionic liquid) were added to an agate mortar in a mass ratio of 100:100 for mechanical Grinding, the grinding time was 40 minutes; the mixture obtained after grinding was transferred to a round bottom flask, and 180 mL of N-methylpyrrolidone (NMP) was added to obtain the first mixed solution;

[0109] 1-c): The above-mentioned first mixed solution is subjected to probe ultrasonication for 3 hours, and the ultrasonic ...

Embodiment 3

[0118] A preparation method of graphene / black phosphorus nanosheet / sulfur-containing ionic liquid composite airgel, comprising the following steps:

[0119] Step (1). Prepare uniform, stable black phosphorus nanosheet solution by liquid phase stripping method, and its specific steps are as follows:

[0120] 1-a): Di(butyl)methylsulfonium hexafluorophosphate (ie sulfur-containing ionic liquid) was vacuum-dried at 110°C for 48 hours;

[0121] 1-b): Add 25 mg of bulk black phosphorus and 5,000 mg of dried di(butyl)methylsulfonium hexafluorophosphate (i.e. sulfur-containing ionic liquid) into an agate mortar in a mass ratio of 100:20,000 for mechanical Grinding, the grinding time was 40 minutes; the mixture obtained after grinding was transferred to a round bottom flask, and 180 mL of N-methylpyrrolidone (NMP) was added to obtain the first mixed solution;

[0122] 1-c): The above-mentioned first mixed solution is subjected to probe ultrasonication for 3 hours, the power is 600W, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com