Embossing roller and preparation device of environment-friendly decorative film

A preparation device and embossing roller technology, which is applied in the direction of printing, rotary printing machines, printing machines, etc., can solve the problems that it is difficult to prepare decorative films with three-dimensional effects and environmental protection properties, and achieve improved valley dyeing effects, clear valley dyeing lines, and three-dimensional strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

[0031] 1Kgf means 1 kilogram force, which is 9.8N.

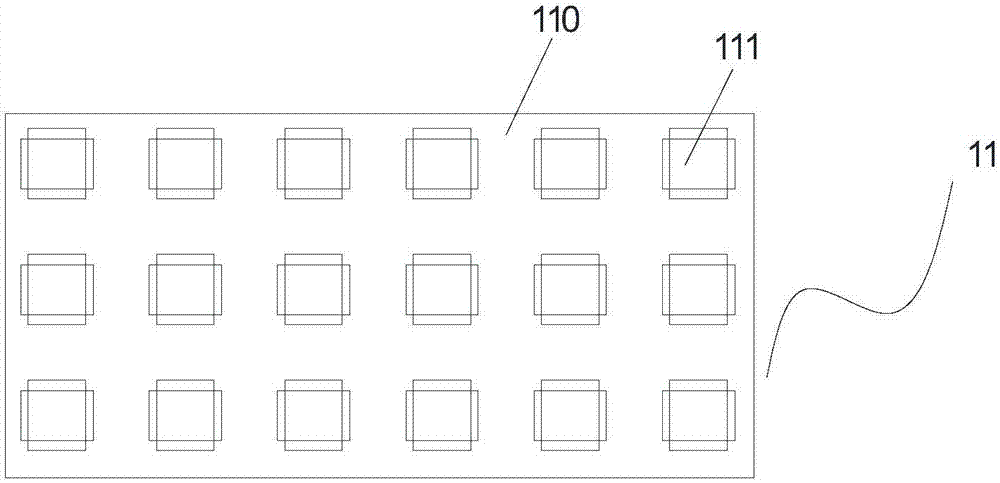

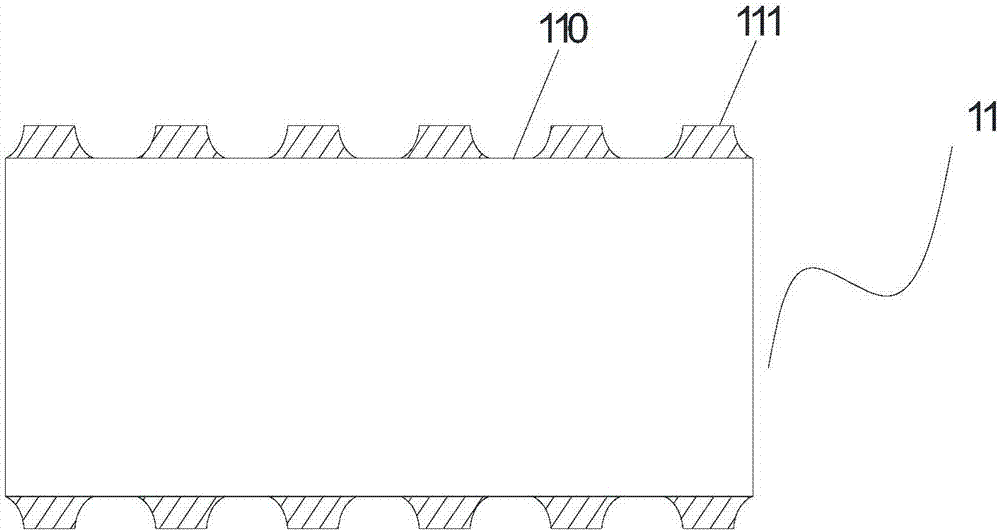

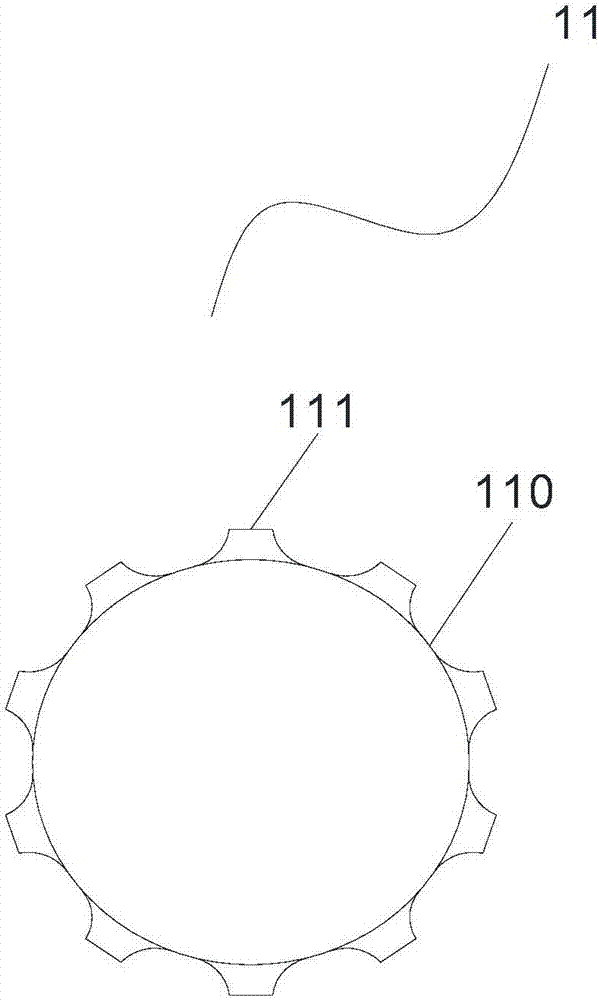

[0032] As mentioned in the background technology section, the preparation device in the prior art has the problem that it is difficult to prepare a decorative film with high environmental performance. In order to solve this problem in the prior art, in a typical embodiment of the present application, an embossing roller is provided, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the embossing roller includes: a roller 110, a protruding structure 111 is arranged on the outer surface of the roller 110, the protruding structure 111 forms a pattern layer, the protruding structure 111 includes a main body A and a connecting part B, and the connecting pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com