Conveying and discharging device for film laminating machine

A technology of laminating machine and conveying roller, applied in the directions of lamination device, transportation and packaging, stack receiving device, etc., can solve the problems of sticking, cost increase, affecting product quality, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

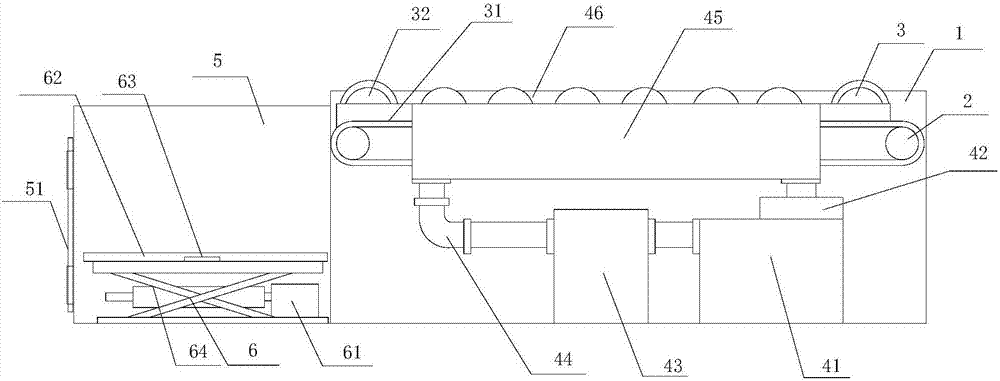

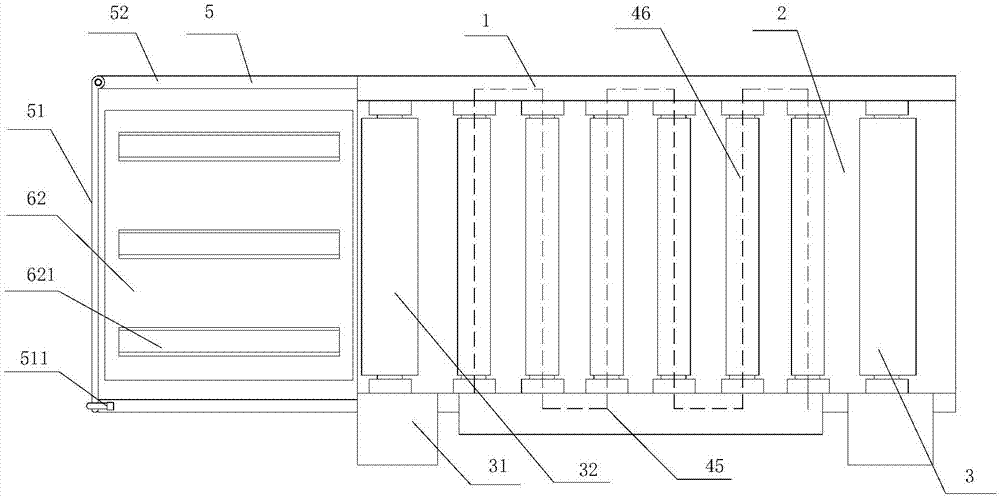

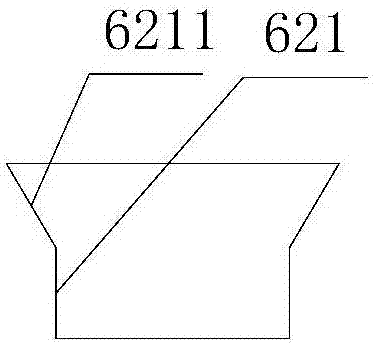

[0015] refer to Figure 1 to Figure 3 A conveying and unloading device for a laminating machine according to the present invention includes a frame 1, a conveyor belt mechanism 2, a conveyor roller assembly 3, a cooling cycle device 4, a feeding box 5 and a lifting platform device 6, and the frame 1 is provided with a conveyor belt mechanism 2, the cooling cycle device 4 is provided with a number of cooling roller assemblies 46, two conveying roller assemblies 3 and cooling roller assemblies 46 are laid on the top of the conveyor belt mechanism 2, and the cooling roller assemblies 46 are evenly distributed on both sides Between the two conveying roller assemblies 3, the two conveying roller assemblies 3 are respectively located at both ends of the conveyor belt mechanism 2, and one side of the conveyor belt mechanism 2 is provided with a lowering box 5, and the lowering box 5 is provided with a lift The table device 6, the lifting table device 6 is provided with a support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com