Paperboard quick coating paper production line

A production line and cardboard technology, applied to layered products, lamination devices, lamination, etc., can solve the problems of low production efficiency of sheet stickers, no automatic feeding and discharging, etc., to achieve good bonding effect, simple structure, and easy output The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

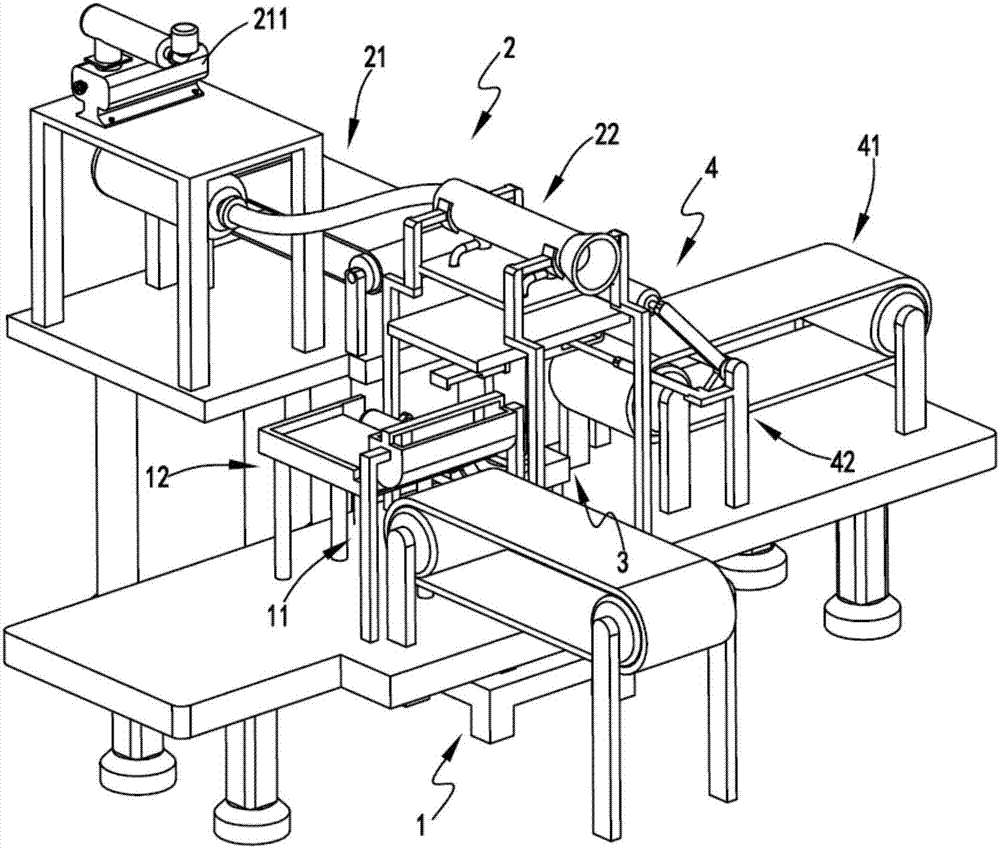

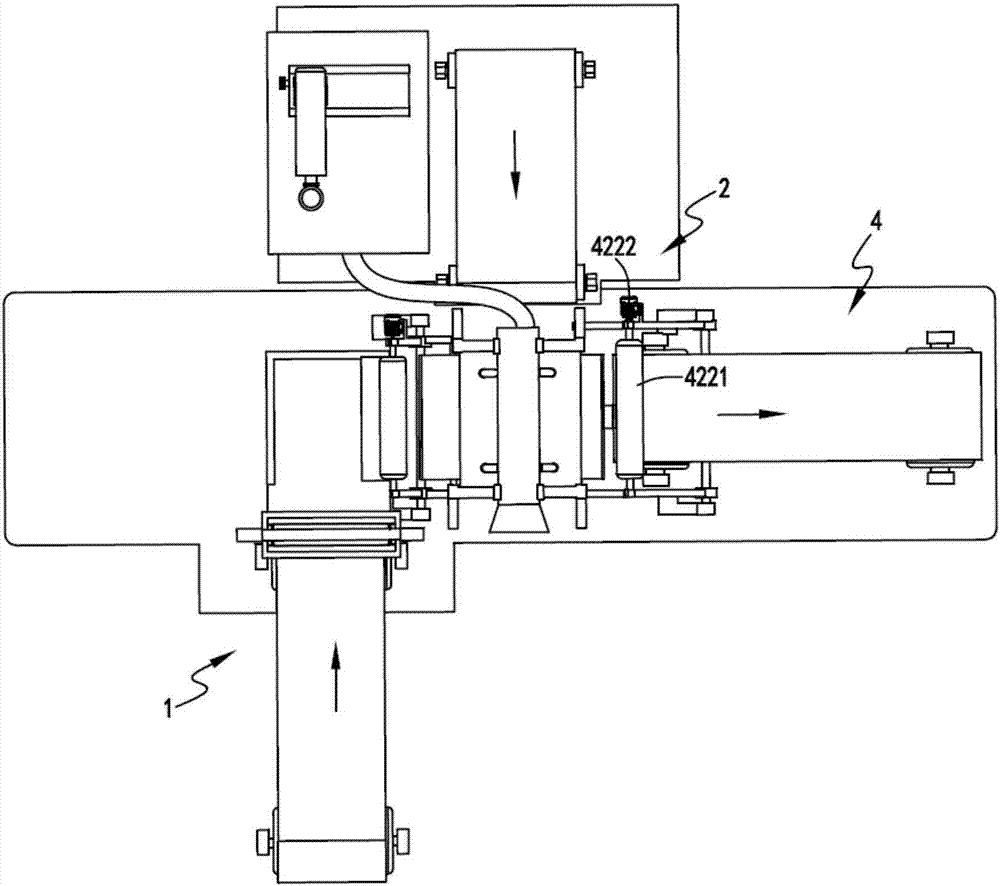

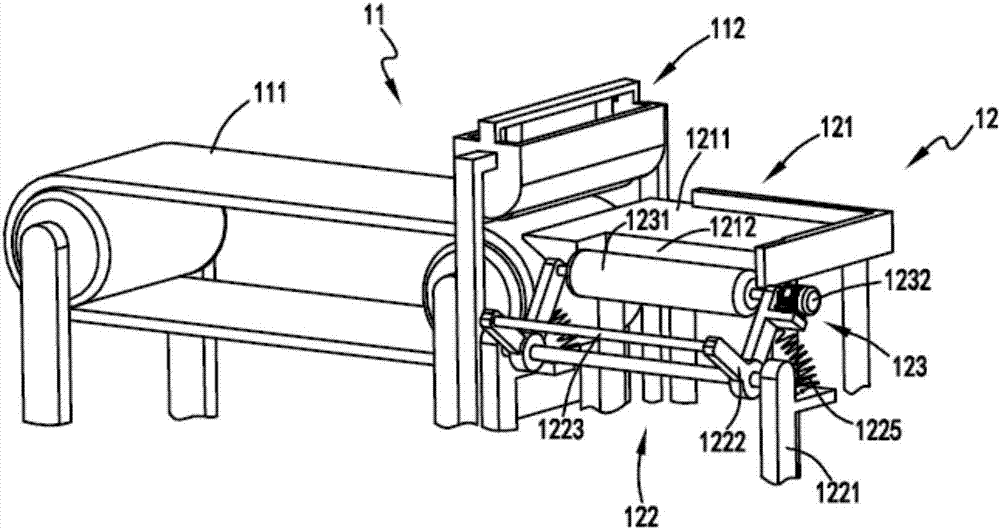

[0040] figure 1 Schematic diagram of the equipment for quickly attaching protective paper to cardboard, figure 2 A schematic top view of the equipment for quickly attaching protective paper to cardboard, image 3 It is a schematic diagram of the structure of the cardboard feeding part, Figure 4 It is a schematic diagram of the structure of the bonding part, Figure 5 It is a schematic diagram of the structure of the feeding part of the protective paper, Figure 6 is a schematic cut-away diagram of the adsorption plate, Figure 7 It is a schematic diagram of the structure when the cardboard and the protective paper start to be laminated, Figure 8 It is a schematic diagram of the structure of the gluing mechanism, Figure 9 It is a schematic diagram of the structure of the negative pressure generating device and the negative pressure adsorption device, Figure 10 It is a schematic diagram of the structure of the rubber box. Such as figure 1 , figure 2 , image 3 , ...

Embodiment 2

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the blower device 221 includes a blower 2211; the negative pressure generating device 222 includes a pipeline 2221 and a number of acceleration elements 2222 arranged in the pipeline 2221, and the acceleration elements 2222 is set in the shape of a cone, and one end with a large opening faces the blower 221; the negative pressure adsorption device 223 includes a negative pressure tube 2231 arranged near the small opening end of the accelerator 2222, and is arranged at the end of the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com