A kind of preparation method of eucommia gum mixed rubber for normal temperature molding processing

A technology of forming processing and eucommia gum, applied in the field of preparing mixed rubber with eucommia gum, can solve the problems of restricting the use of eucommia rubber and its composite materials, complex extraction process of eucommia gum, and large amount of raw materials, etc., so as to improve processing safety. , Processability and physical properties improvement, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] (1) Put the natural rubber into the open mill and masticate (at room temperature) for 10-20 minutes to cover the roll, park it for 3-5 hours, then add carbon black and plasticizer to the parked natural rubber to make natural rubber Raw rubber masterbatch.

[0026] (2) Put the Eucommia gum into the open mill for mastication (control the processing temperature at 50°C-70°C) for 10-15 minutes to cover the roll, then add 4 parts of zinc oxide, 2 parts of stearic acid, 2 parts of 4010NA, 1.2 parts of NOBS, 2.5 parts of sulfur, after the rubber materials are fully mixed and masticated, the eucommia compound rubber is made.

[0027] (3) Add Eucommia mixed rubber and natural raw rubber masterbatch to the open mill (at room temperature) at the same time, beat the triangular bag several times until it is evenly mixed, and stop the next piece.

[0028] (4) After the rubber compound is parked for 24 hours, it can be molded.

[0029] (5) Put the plasticized blend into the mold, he...

Embodiment

[0030] Implementation example: Utilize a preparation method of eucommia gum combined with glue for normal temperature molding processing. Carry out tests according to the following formula scheme, and obtain relevant implementation results.

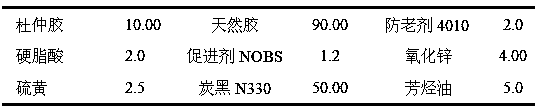

[0031] Table 1: Embodiment 1 formulation (phr)

[0032]

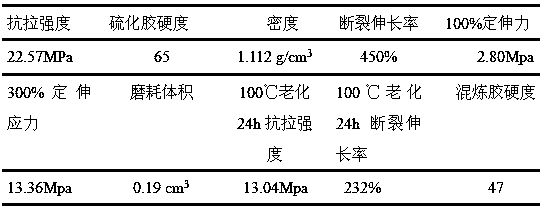

[0033] Table 2: Physical properties of embodiment 1 sample

[0034]

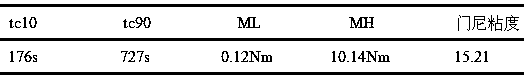

[0035] Table 3: Vulcanization characteristics of the samples of embodiment 1

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com