oca optical glue die-cutting process

An optical adhesive and die-cutting technology, applied in metal processing, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of bubble overflow, uneven laying, and scrapping of OCA, and achieve stable antistatic performance, Reduce the edge overflow problem and protect the effect of OCA layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

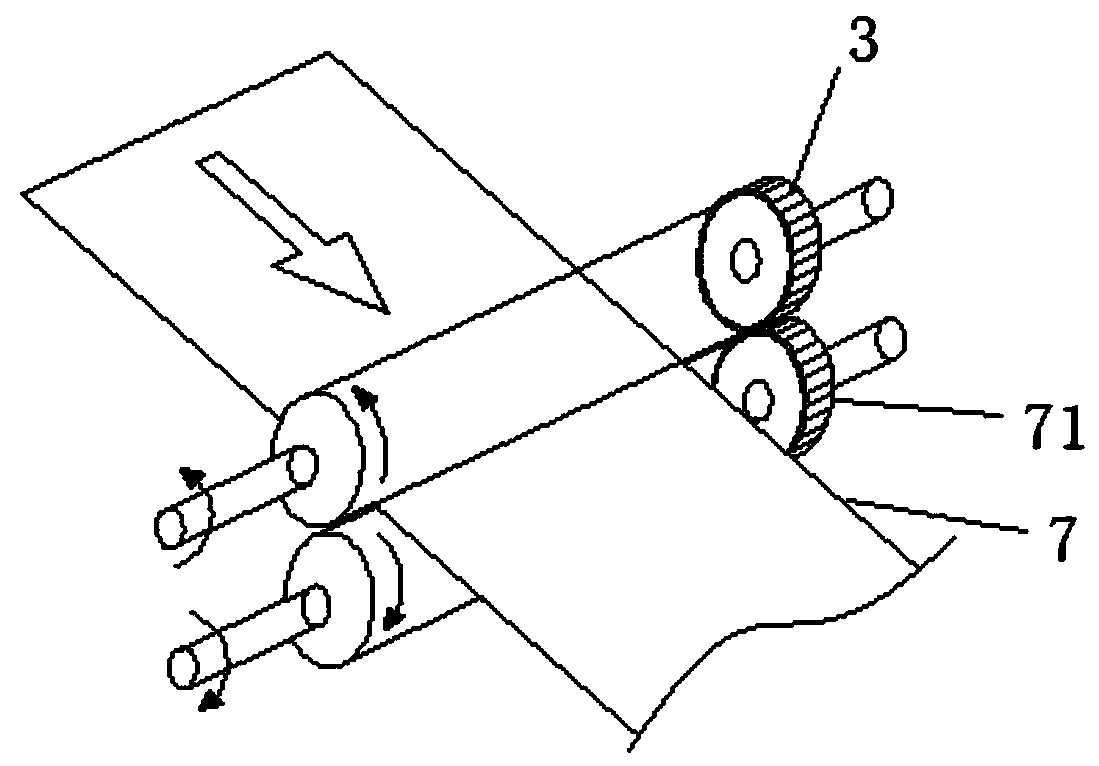

[0026] refer to Figure 1-3 As shown, the present embodiment is an OCA optical adhesive die-cutting process, which includes the following steps: S1. The die-cutting operation environment of OCA optical adhesive directly affects the product quality of roller knife die-cutting. The operating environment is a thousand-class clean room, and the temperature is controlled at 24-26°C, humidity 80-90%, the relative static electricity is reduced, and the dust particles in the air are reduced on the product.

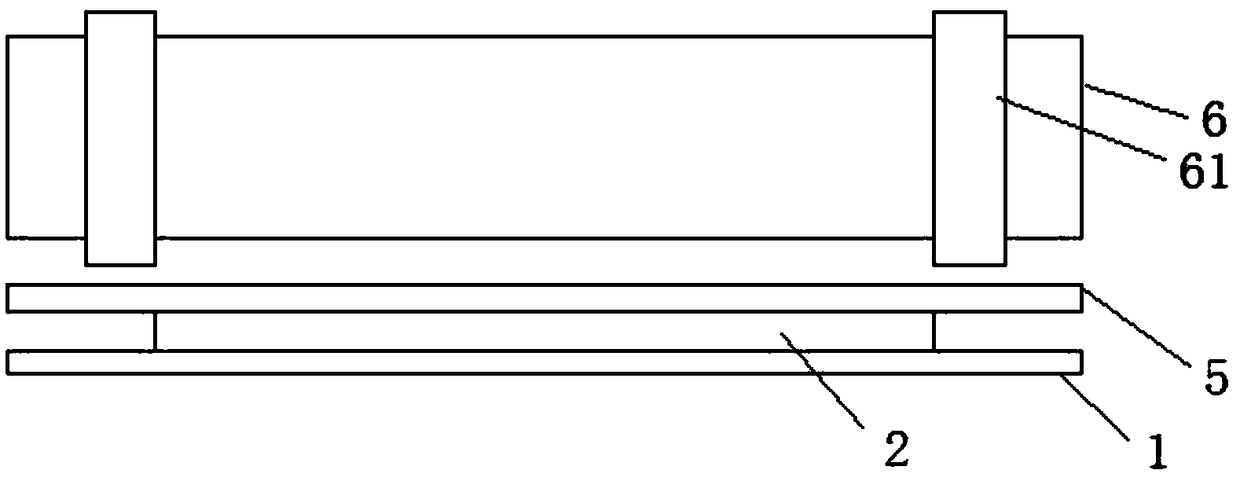

[0027] S2, slitting raw materials, OCA is a double-sided adhesive without substrate, with high fluidity, and heavy pressure should be avoided. When slitting raw materials, use a dust-free cloth dipped in alcohol to moisten and remove dust on the edge of the slitting knife, and then cut the raw material into small coils to avoid edge lint. Hang the cut material on the material rack.

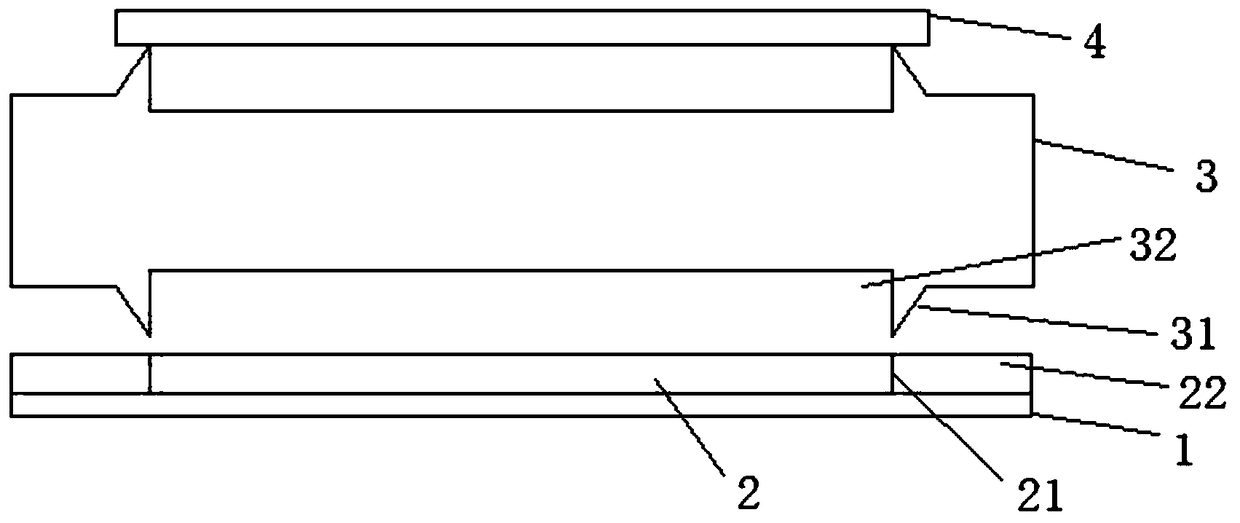

[0028] S3, change the film, OCA optical adhesive itself has a heavy release film 1 on the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com