Feeding and discharge stock bin for grinding of bearing rings

A bearing ring and silo technology, applied in the direction of grinding feed motion, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of easy dumping of finished products, difficulty in finishing, and high labor costs, so as to facilitate subsequent operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

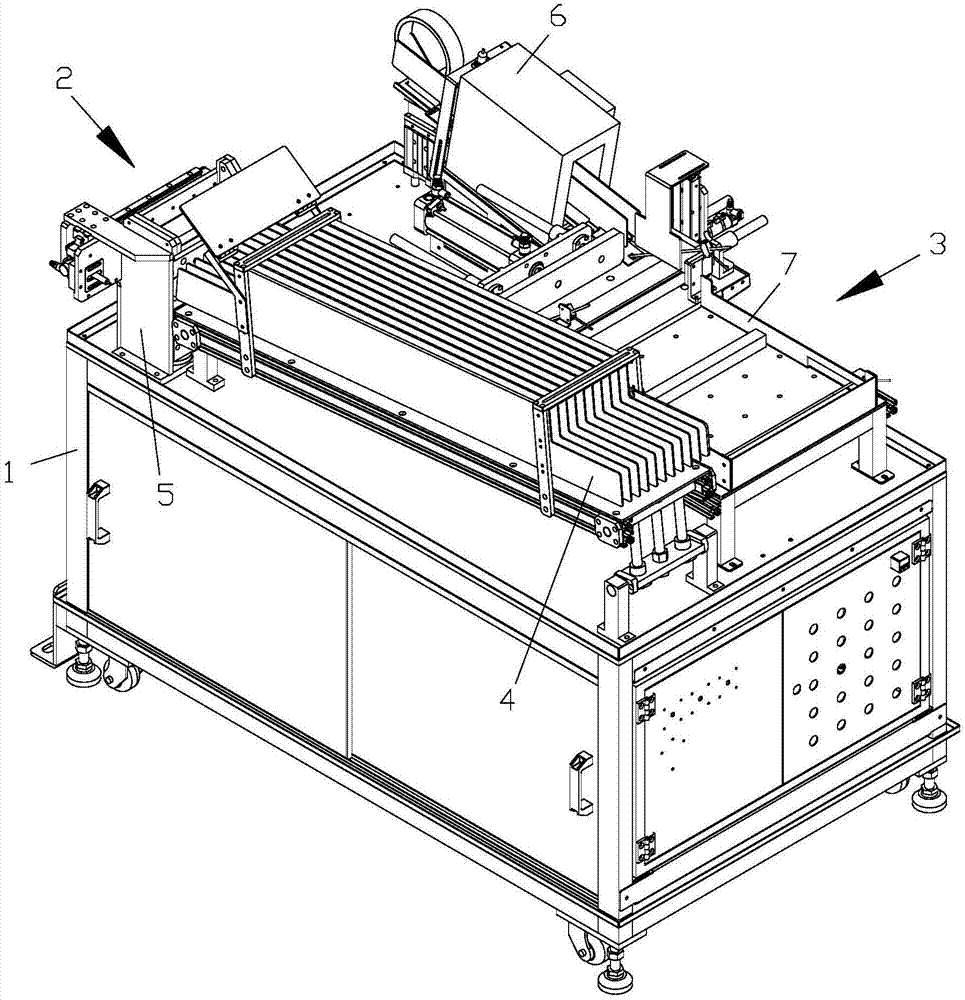

[0029] One of the specific implementation methods, such as Figure 1~4 Shown:

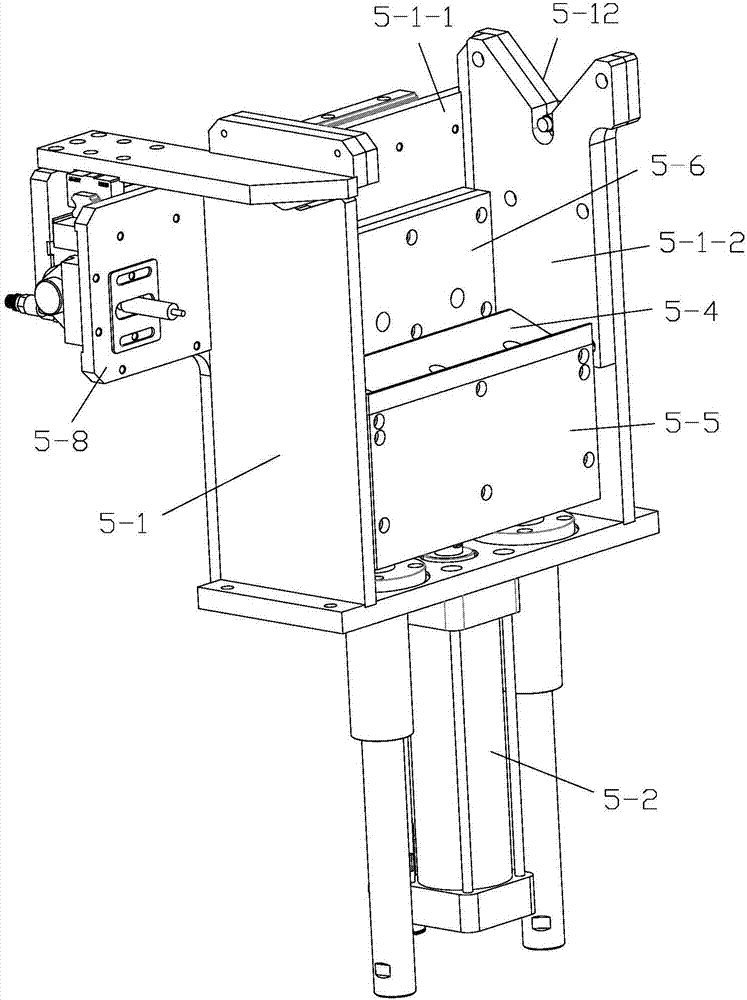

[0030] A bearing ring grinding loading and unloading material bin, including a frame 1, the two sides of the frame 1 are respectively provided with a rough material bin 2 and a finished product material bin 3, and the blank material bin 2 includes a feeding gravity feeder 4 and a feeding top Lifting mechanism 5, finished product bin 3 includes demagnetization mechanism 6 and finished product pushing mechanism 7, bearing ring channel grinding rough parts are put into rough material bin 2, bearing ring channel grinding finished parts are put into finished product bin 3, of which,

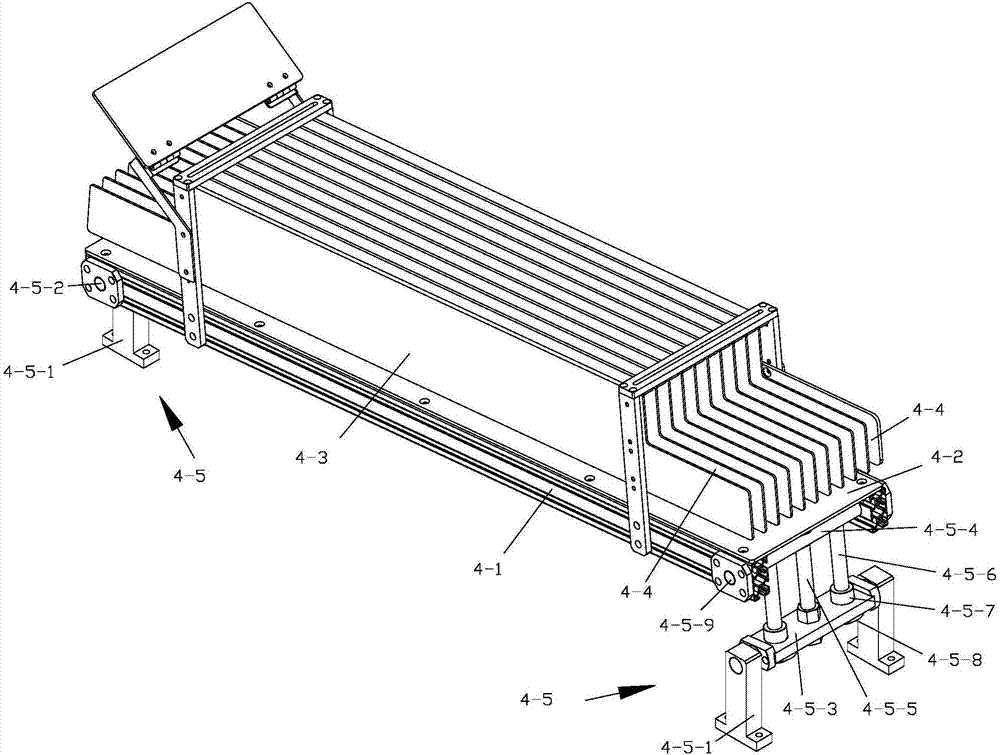

[0031] -The feeding gravity chute 4 includes 2 chute frames 4-1, the top of the 2 chute frames 4-1 has a slideway plate 4-2, and the slideway plate 4-2 is provided with a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com