Bend coated steel machining method for angle-steel tower

A processing method, the technology of angle steel tower, which is applied in the field of angle steel tower fire-curved steel processing, can solve the problems of tearing damage of base metal, damage of base metal, manual flame cutting operation is not easy to control, etc., to solve the problem of unstable processing quality , Guarantee the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

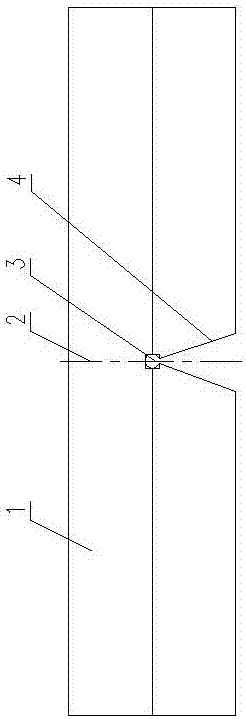

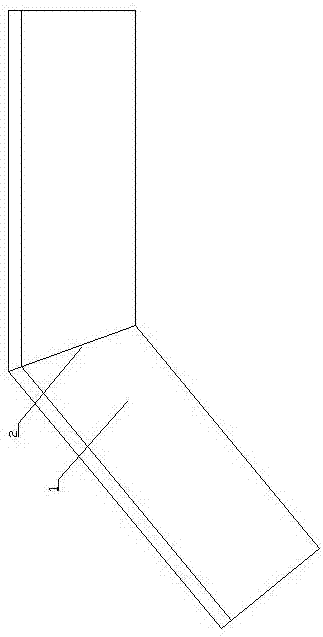

[0016] A method for processing steel-curved steel of an angle steel tower, comprising the following steps successively:

[0017] (1) Process a plane on the back side of the hot bending position of the angle steel 1, and drill a process hole 3 on the plane. In this embodiment, the method of machining a plane on the back side of the hot bending position of the angle steel 1 is: machining with a file.

[0018] Wherein, in order to improve the quality of the finished product, the surface of the angle steel 1 needs to be cleaned before step (1), and the cleaning method is: water washing or air blowing; wherein, tap water is used for water washing. After cleaning the angle steel 1 with water, it needs to be dried before proceeding to step (1), wherein the method of drying is: natural drying. In this embodiment, using tap water to clean the surface of the angle steel 1 can remove impurities on the surface of the angle steel 1; and using natural drying method can avoid damage to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com