In-in-situ remediating method for oil-contaminated soil

A technology of oil pollution and remediation method, which is applied in the field of in-situ remediation of oil-contaminated soil, which can solve the problems of poor degradation effect of high-concentration oil-contaminated soil, restrictions on large-scale application of bioremediation, high cost of bacterial agents, etc., and achieve soil ecotoxicity Decrease, good repair effect, effect of reducing repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mineralized waste with a landfill age of 8 years was collected in the sanitary landfill of domestic waste, passed through a sieve with an aperture of 10 mm, and mineralized waste with a particle size of less than 10 mm was obtained for use.

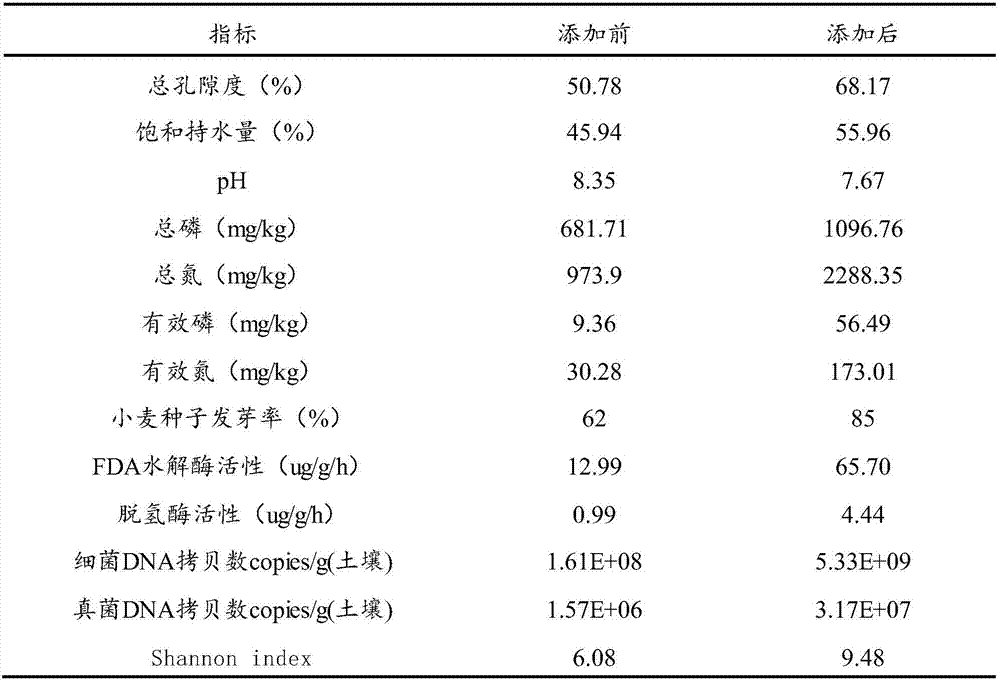

[0029] Add the above sieved mineralized waste into the oil-contaminated soil (with a petroleum hydrocarbon content of 50g / kg) in situ according to the mass ratio of the mineralized waste to the oil-contaminated soil at a ratio of 1:1, and stir evenly. Contaminated soil without mineralized waste was used as a control. Table 1 shows the changes in the physical, chemical and biological properties of the contaminated soil before and after adding mineralized waste.

[0030] Table 1 Changes of soil physical, chemical and biological properties before and after adding mineralized waste

[0031]

[0032] From the data in Table 1, it can be seen that after adding mineralized waste, the ecotoxicity of the soil was greatly reduced, and the...

Embodiment 2

[0037] Mineralized waste with a landfill age of 13 years was collected in the sanitary landfill of domestic waste, passed through a sieve with an aperture of 10 mm, and mineralized waste with a particle size of less than 10 mm was obtained for use.

[0038] Add the above sieved mineralized waste into the oil-contaminated soil (with a petroleum hydrocarbon content of 50g / kg) in situ according to the mass ratio of the mineralized waste to the oil-contaminated soil at a ratio of 1:1, and stir evenly. Contaminated soil without mineralized waste was used as a control.

[0039] After the mineralized garbage is mixed with the petroleum-contaminated soil, a mixed soil is obtained, and the petroleum hydrocarbons in the mixed soil are gradually degraded. The temperature of the mixed soil is controlled at 25°C, and water is added regularly to maintain a moisture content of 15wt% of the mixed soil. Plowing is performed every 4 days.

[0040] After 42 days of degradation, the degradation r...

Embodiment 3

[0047] Mineralized waste with a landfill age of 8 years was collected in the sanitary landfill of domestic waste, passed through a sieve with an aperture of 10 mm, and mineralized waste with a particle size of less than 10 mm was obtained for use.

[0048] In the oil-contaminated soil with petroleum hydrocarbon content of 30g / kg, 50g / kg, 100g / kg, 200g / kg, and 300g / kg, add the above-mentioned sieved oil according to the mass ratio of mineralized waste to petroleum-contaminated soil at a ratio of 1:1. Mineralize the litter and mix well. Contaminated soil without mineralized waste was used as a control.

[0049] After the mineralized garbage is mixed with the petroleum-contaminated soil, a mixed soil is obtained, and the petroleum hydrocarbons in the mixed soil are gradually degraded. The temperature of the mixed soil is controlled at 25°C, and water is added regularly to maintain a moisture content of 15wt% of the mixed soil. Plowing is performed every 4 days.

[0050] After 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com