Vacuum decompression drying device

A technology of drying equipment and vacuum decompression, applied in optics, instruments, nonlinear optics, etc., can solve problems such as uneven coloring, achieve the effects of reducing uneven air distribution, preventing uneven coloring, and improving uneven coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

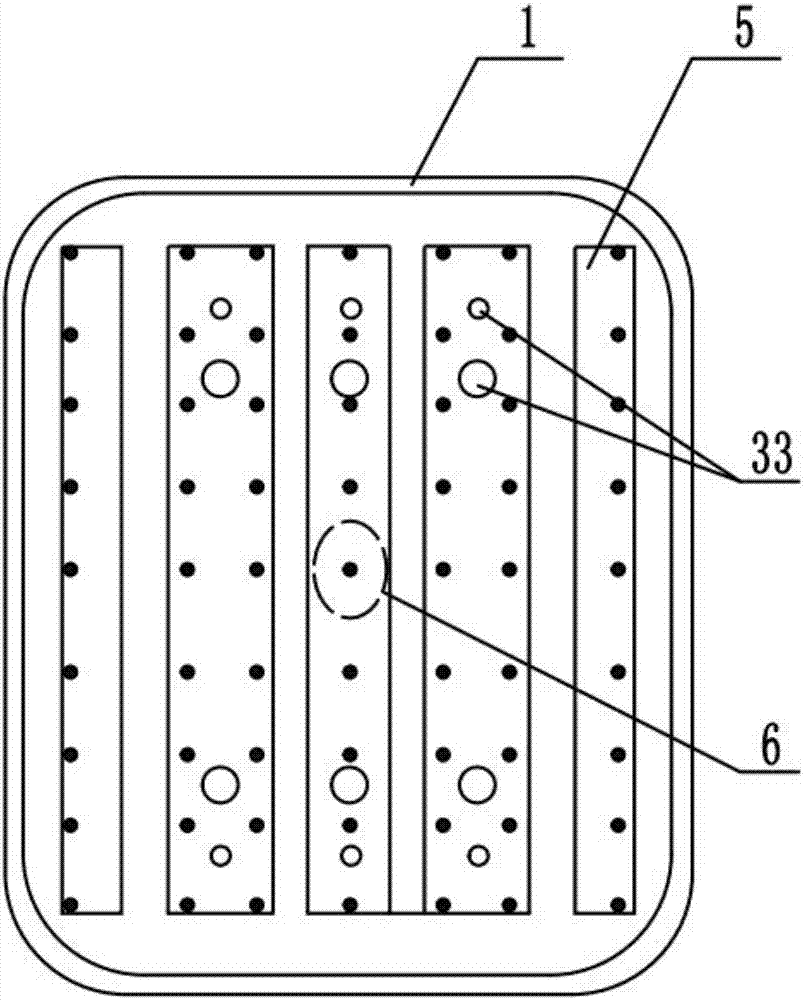

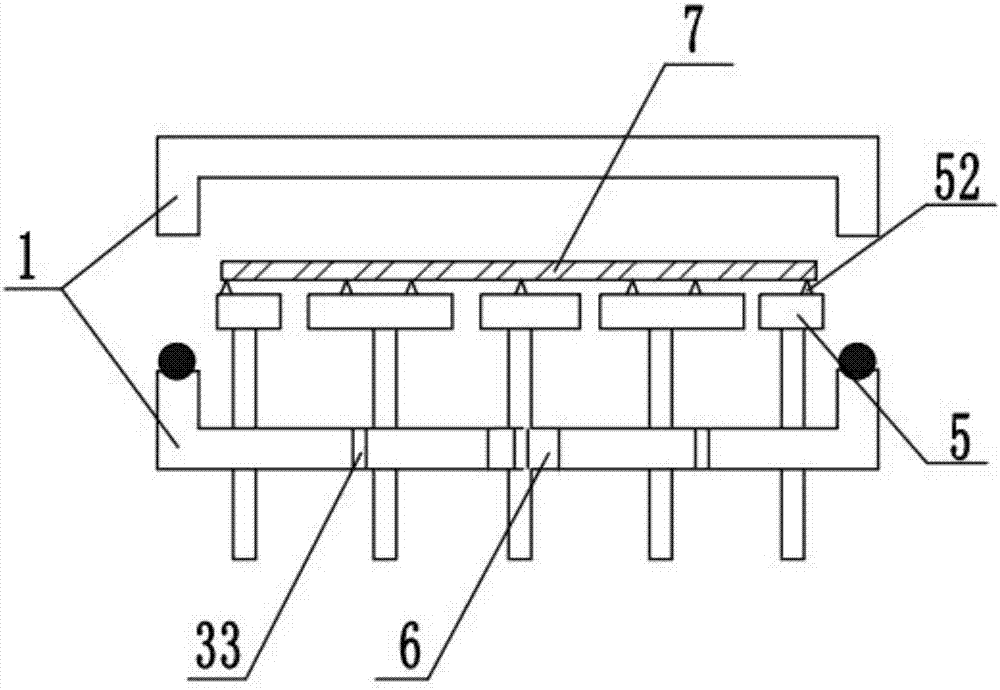

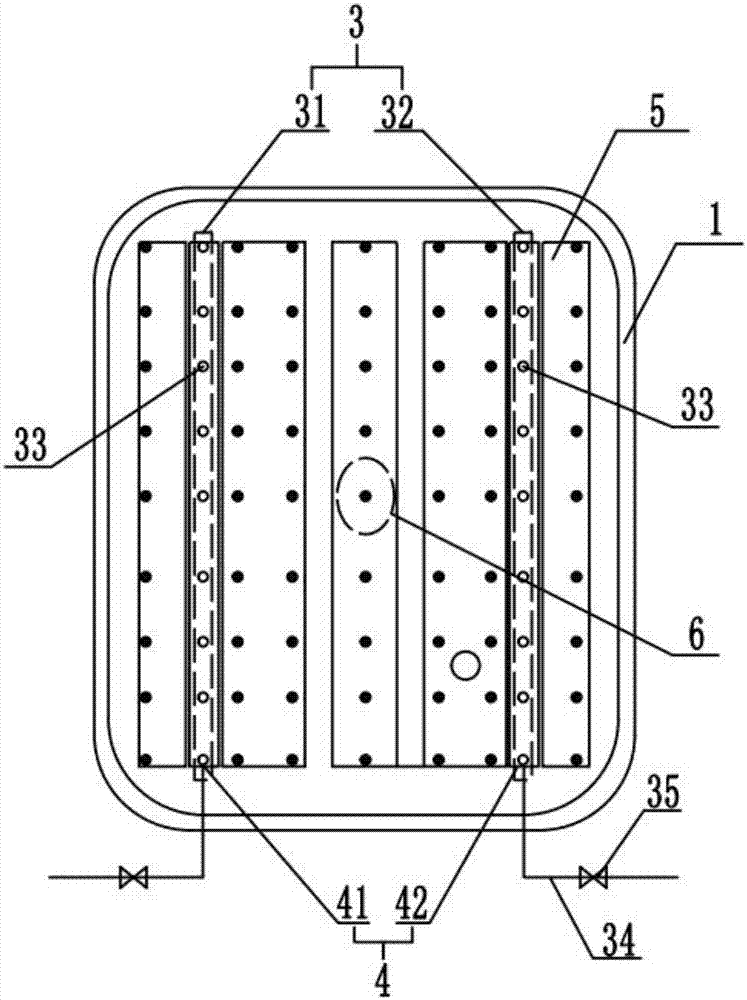

[0035] Such as image 3 As shown, the present invention provides a vacuum decompression drying equipment, which includes: a cover plate 1 and a chamber 2 inside the cover plate 1, the substrate is arranged in the chamber 2; Vacuum device 3; Vacuum breaking device 3 at least includes a first blowing hole array 31 and a second blowing hole array 32, and the first blowing hole array 31 and the second blowing hole array 32 all include multiple holes arranged along the long side direction of the cover plate 1 A blow hole 33. The blowing hole 33 is used to pass dry air (CDA) into the chamber 2 to restore the air pressure in the chamber 2 .

[0036] Such as image 3 As shown, the first row of blowing hole arrays 31 is close to the side wall of the cover plate 1 in the longitudinal direction, and the second row of blowing holes 32 is close to the other side wall of the cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com