Rotary nozzles for high-pressure cleaning equipment

一种旋转喷嘴、高压清洁的技术,应用在具有活动出口的喷洒装置、喷射装置等方向,能够解决降低流体束清洁效果、流体束散开等问题,达到造型容易、低成本、低制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

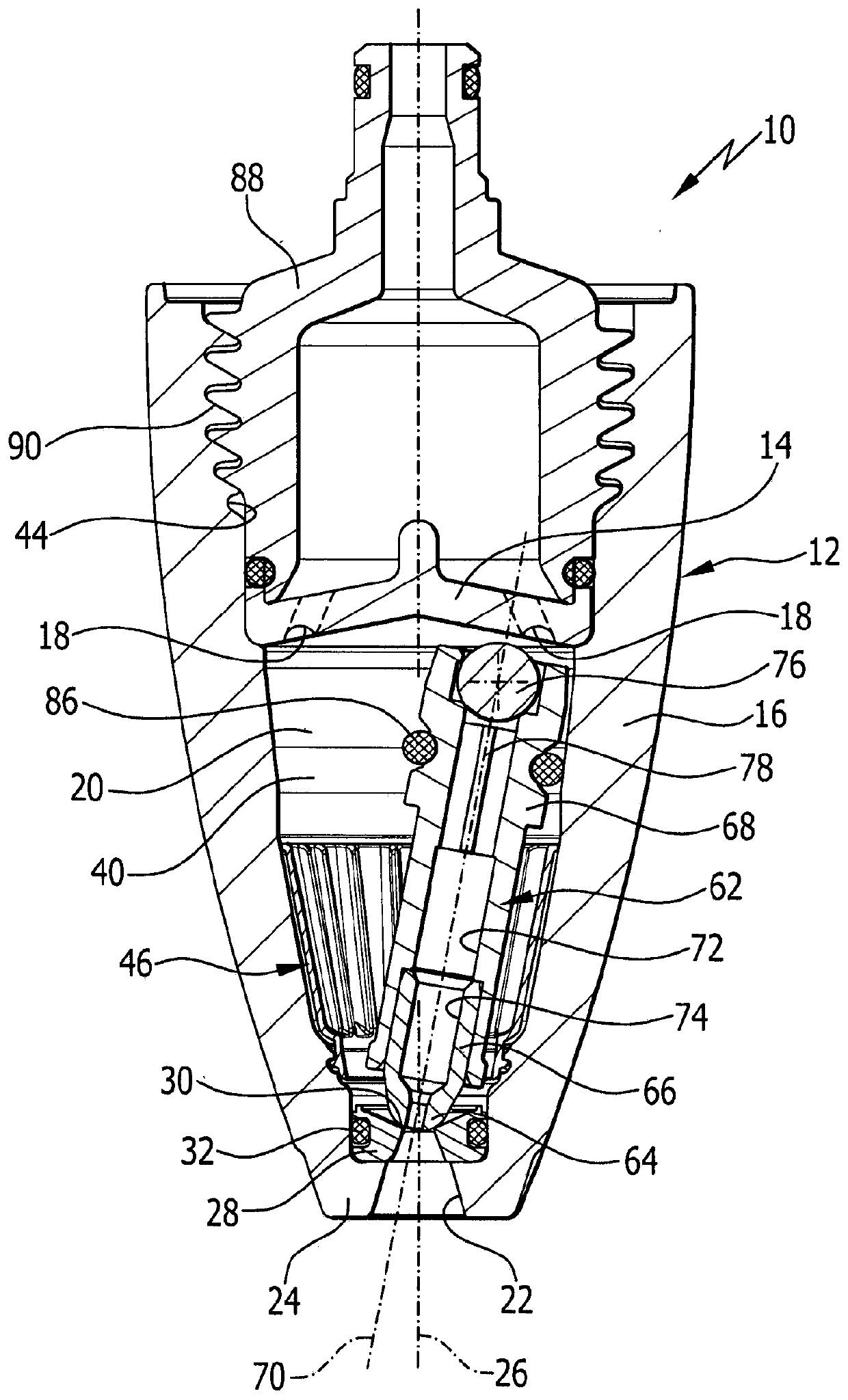

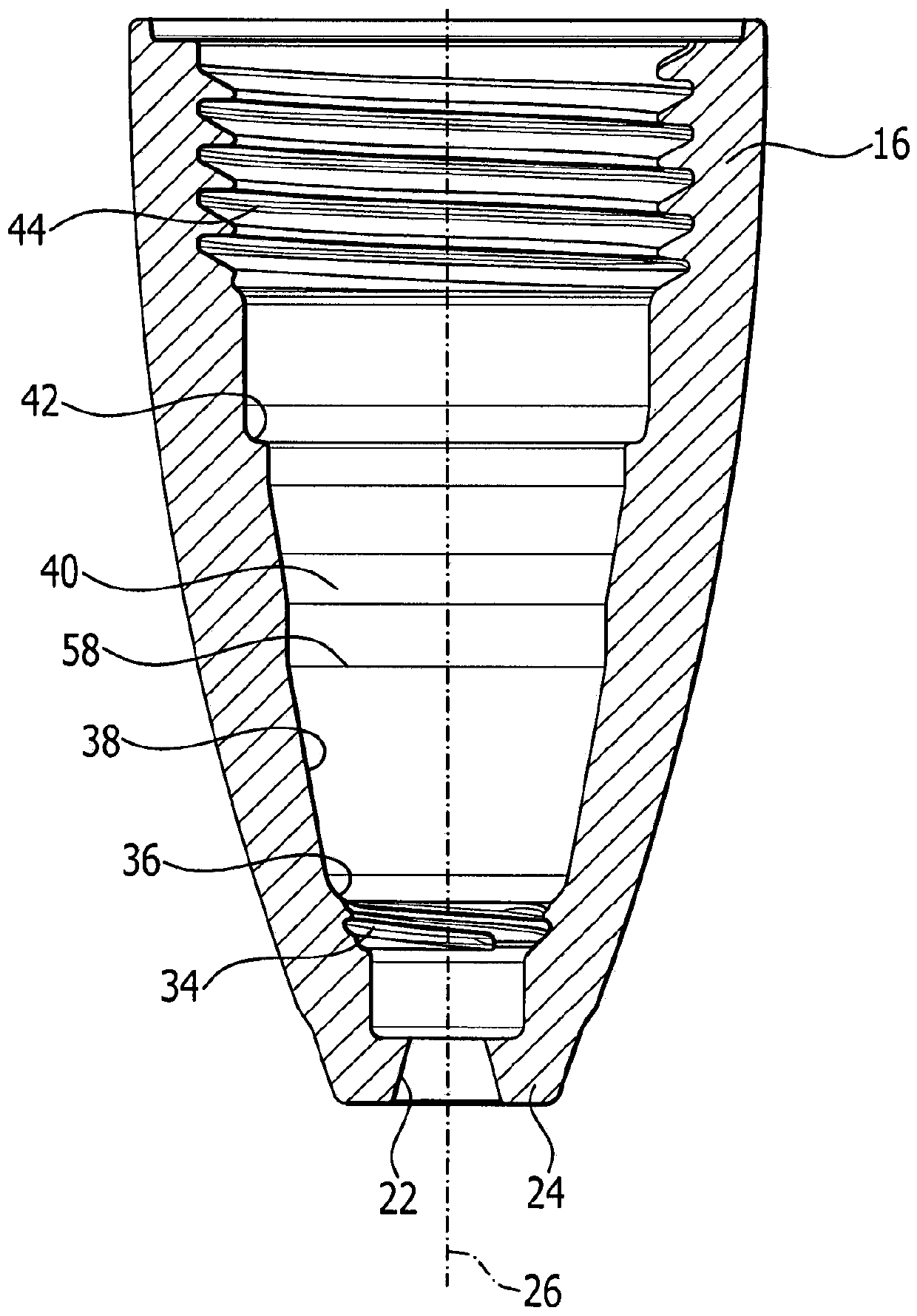

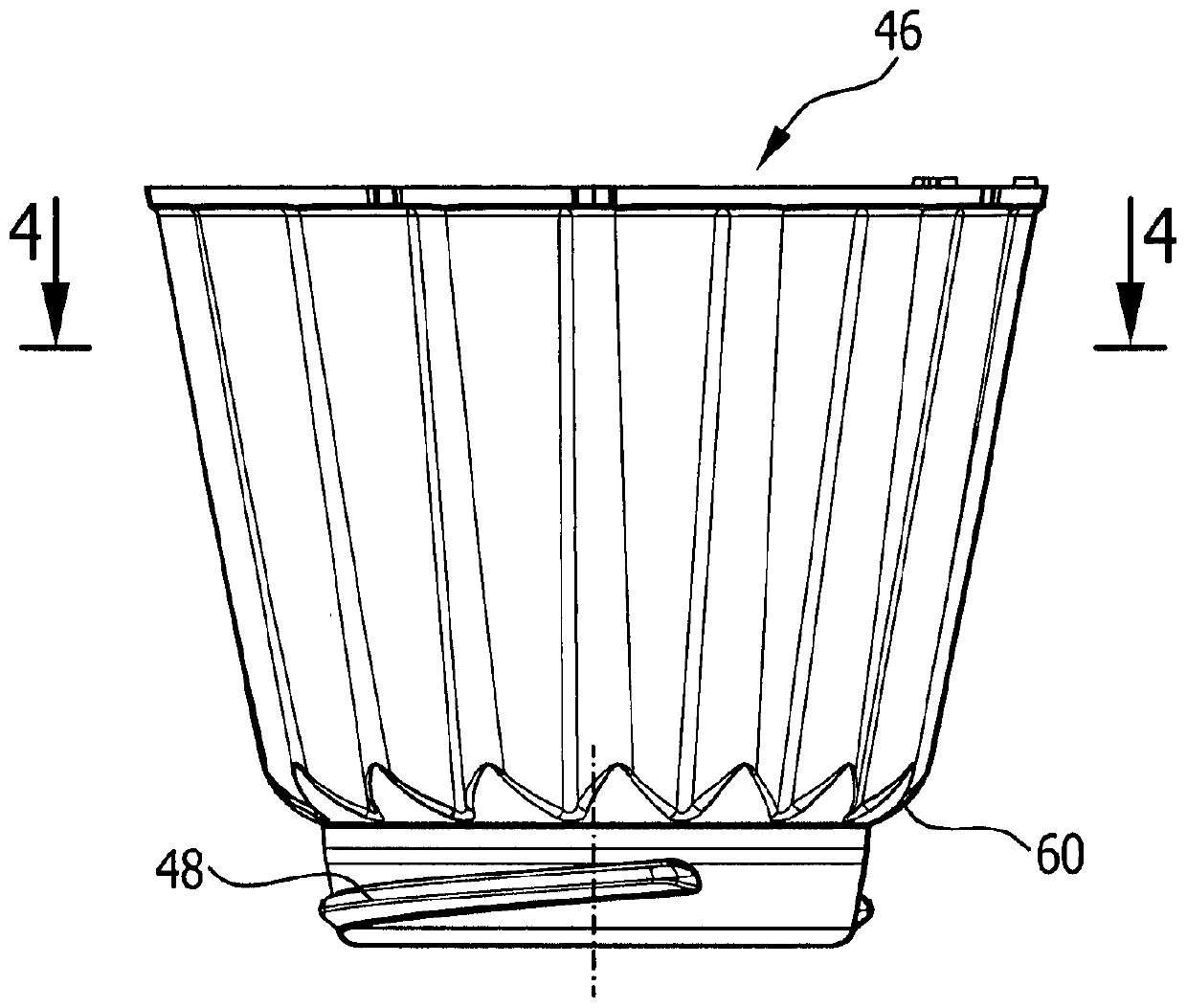

[0038] exist Figures 1 to 4 A first advantageous embodiment of the rotary nozzle according to the invention is schematically shown in FIG. 1 , which is designated as a whole by the reference numeral 10 . The rotary nozzle 10 has a housing 12 with a housing bottom 14 and a housing cover 16 . The housing bottom 14 is designed in the shape of a plate and has a plurality of tangential openings 18 , which open into the interior 20 of the housing 12 . The inner chamber 20 is surrounded by the housing cover 16 and narrows from a tangential inlet 18 to an outlet 22 arranged on an end wall 24 of the housing cover 16 .

[0039] Via the tangential inlet 18 , a fluid under pressure can be supplied to the inner chamber 20 , which rotates in the inner chamber 20 about the housing longitudinal axis 26 and can escape from the housing 12 via the outlet 22 .

[0040] Arranged in the inner chamber 20 immediately upstream of the outlet opening 22 is a bearing in the form of a bearing ring 28 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com