A visual online detection method and system for powder coating quality of laser selective melting forming

A technology of laser selective melting and detection method, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of difficult promotion and high cost of infrared thermal imaging cameras, and achieve significant economic benefits, reduce production costs, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

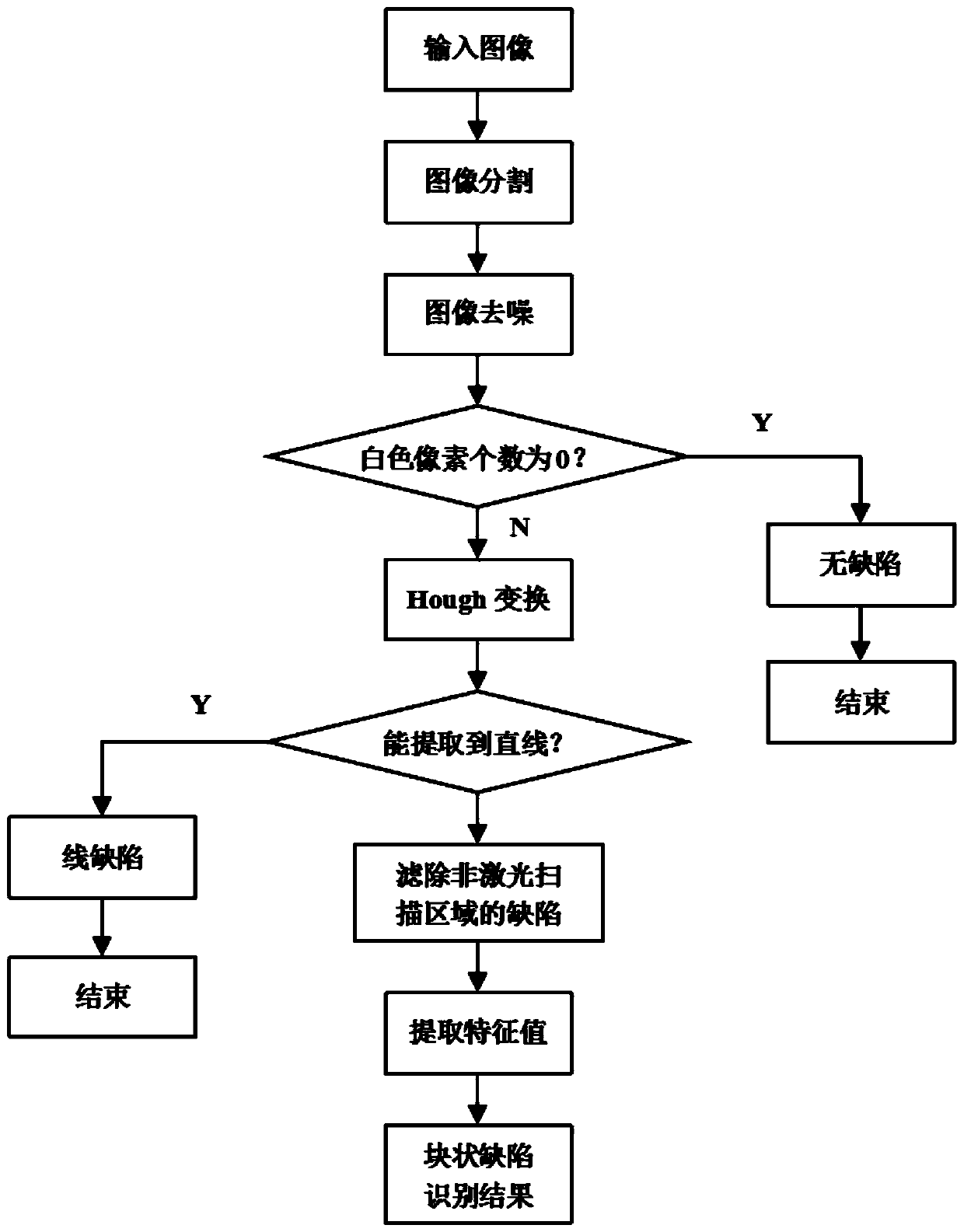

[0066] Referring to Figure 5(a), it can be seen that there are high cladding layer defects (block defects) in this figure, which are processed by using the above-mentioned adaptive double threshold segmentation method. The steps of segmenting block defects are as follows:

[0067] (1) Select 200×200 sub-blocks to traverse each pixel of the image, and perform the following processing on each pixel in the image:

[0068] G out =G in -μ l +μ src

[0069] Among them, G out is the processed pixel gray value, G in is the pixel gray value before processing, μ l is the mean value of the gray value of all pixels in the current sub-block, μ src is the mean value of the gray values of all pixels in the original image;

[0070] (2) Obtain the mean value μ and standard deviation σ of the image pixel gray level after processing;

[0071] (3) Traverse each pixel of the image, when the gray value of the pixel is greater than μ+2σ or less than μ-2σ, set the gray value of the pixel t...

Embodiment 2

[0074] Referring to Figure 5(a), it can be seen that there are stripe-shaped defects (horizontal line defects) in this figure, which are processed by the above-mentioned adaptive double threshold segmentation method. The steps of segmenting horizontal line defects are as follows:

[0075] (1) Select 5×30 sub-blocks to traverse each pixel of the image, and process each pixel in the image as follows: G out =G in -μ l +μ src

[0076] Among them, G out is the processed pixel gray value, G in is the pixel gray value before processing, μ l is the mean value of the gray value of all pixels in the current sub-block, μ src is the mean value of the gray value of all pixels in the original image;

[0077] (2) Obtain the mean value μ and standard deviation σ of the image pixel gray level after processing;

[0078] (3) Traversing each pixel of the image, when the pixel gray value is greater than μ+1.5σ or less than μ-1.5σ, set the pixel gray value to 255, otherwise set it to 0.

...

Embodiment 3

[0081] Referring to Figure 5(a), it can be seen that there are long strips of powder pile defects (vertical line defects) in this figure, which are processed by the above-mentioned adaptive double threshold segmentation method. The steps of segmenting vertical line defects are as follows:

[0082] (1) Select 30×5 sub-blocks to traverse each pixel of the image, and perform the following processing on each pixel in the image:

[0083] G out =G in -μl +μ src

[0084] Among them, G out is the processed pixel gray value, G in is the pixel gray value before processing, μ l is the mean value of the gray value of all pixels in the current sub-block, μ src is the mean value of the gray values of all pixels in the original image;

[0085] (2) Obtain the mean value μ and standard deviation σ of the image pixel gray level after processing;

[0086] (3) Traversing each pixel of the image, when the pixel gray value is greater than μ+1.5σ or less than μ-1.5σ, set the pixel gray val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com