Method for splicing closed filter container and rotating handle of water purifier and filter container device

A water purifier and bile filter technology, which is applied in chemical instruments and methods, ultrafiltration, water/sewage treatment and other directions, can solve the problems of hidden dangers of water purifiers, difficult to filter bile locking mechanism, etc. Cost of use, easy to connect or disconnect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

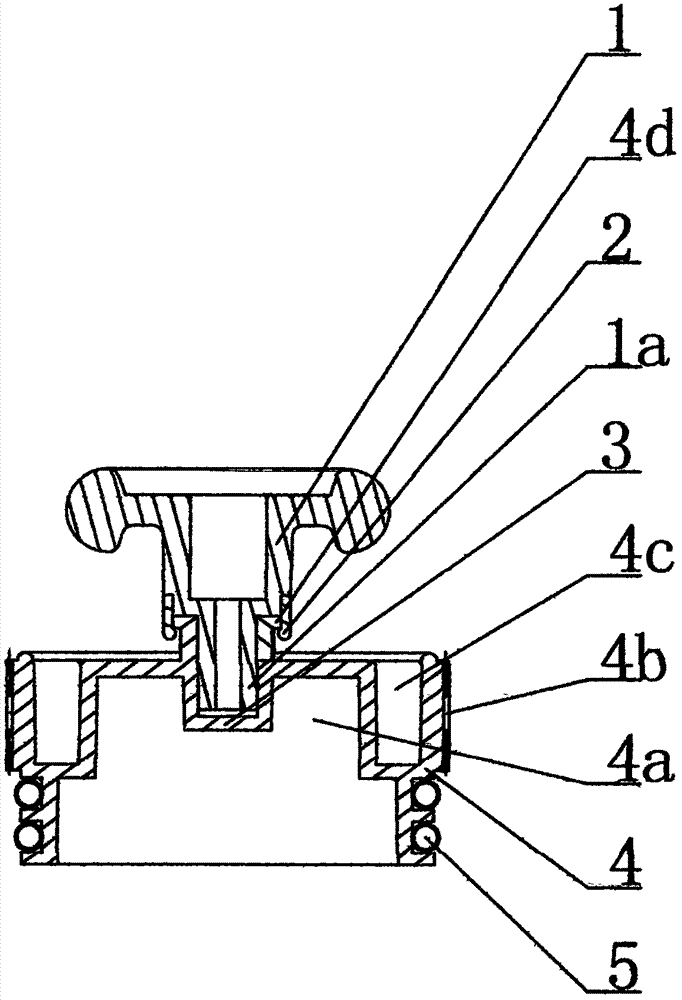

Embodiment 1

[0023]Example 1. The lower part of the closed filter gallbladder and the cavity of the machine base are screwed together to form an integral body, that is, the inner side of the closed filter gallbladder and the cavity of the machine base where the closed filter gallbladder is placed are respectively provided with thread structures corresponding to the threaded joints, and the closed filter gallbladder passes through The thread structure is axially screwed into the cavity of the fixed machine base and plugged with the water outlet provided on the bottom surface of the cavity of the machine base. The two sides of the filter material layer are respectively connected to two water ports including the external water port, and connected to the machine base cavity in series. The water outlet on the bottom surface of the body constitutes a water passage for sealing the filter gall. The closed filter gall located at the high position of the screw connection moves downward by itself dur...

Embodiment 2

[0028] Example 2. On the basis of the two plug-in fit modes in Embodiment 1, the threaded screw joint structure used for the screw joint fit between the machine base cavity and the lower part of the closed filter gall is changed to a screw clamp connection structure. The cavity of the machine base and the lower part of the closed filter gallbladder are connected by a screw clamp structure in which the concave tooth buckle and the convex tooth buckle are axially inserted and screwed together. The concave-convex axial insertion and rotation linkage structure provided on the upper surface of the shell of the closed filter gall is matched with the axial insertion of the rotary handle with the convex-concave plug. Change.

[0029] Similarly, the cavity of the machine base and the lower part of the closed filter gall can also be connected by a screw clamp connection structure in which the convex tooth buckle and the concave tooth buckle are axially inserted and screwed together.

...

Embodiment 3

[0031] Example 3. On the basis of Examples 1 and 2, the closed filter gall adopts an assembled closed filter gall with a filter cartridge cavity and a chamber cover screwed together to form a closed cavity and a built-in filter gall is placed. Machine filter gallbladder adopts open filter gallbladder. The bottom surface of the filter cartridge cavity is provided with a water outlet; the built-in filter gall is placed in a closed cavity formed by a screw connection between the upper part of the filter cartridge cavity and the chamber cover, and is sealed and matched with the corresponding water outlet of the filter cartridge cavity. Both sides of the filter material layer are respectively connected to the corresponding water outlets of the filter cartridge cavity to form a water passage; the screw connection structure is either an axial screw connection structure through a thread structure, or an axial mutual insertion through concave and convex tooth buckles. The screw connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com