Automatic film stripping equipment

An equipment and automatic technology, applied in the field of machinery, can solve the problems of improving product scrapping rate, product scrapping, low efficiency, etc., achieving the effect of simple and compact structure design, compact structure design, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

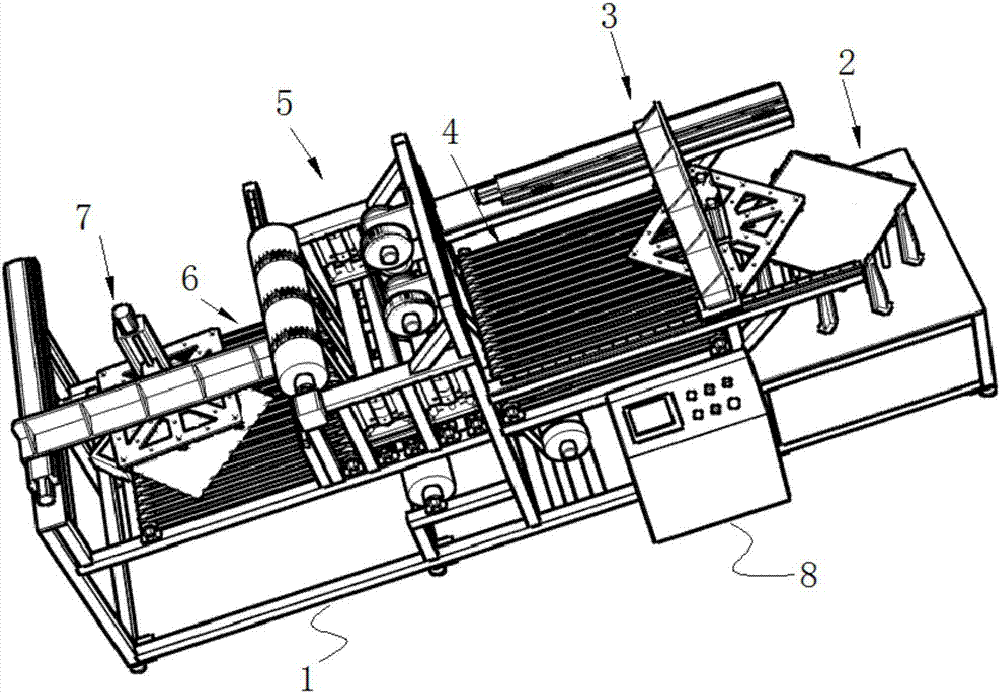

[0037] Embodiment: a kind of automatic film tearing equipment, as Figure 1-Figure 5 As shown, it includes a bracket 1, and includes a feeding mechanism 2, a first retrieving mechanism 3, a first conveying mechanism 4, a film tearing mechanism 5, a second conveying mechanism 6 and a second retrieving mechanism 7 according to the product manufacturing process. The mechanism 2 is fixed on one end of the bracket 1, and the first feeding mechanism 3, the first delivery mechanism 4, the film tearing mechanism 5, the second delivery mechanism 6 and the second feeding mechanism 7 are all fixed on the bracket 1 superior;

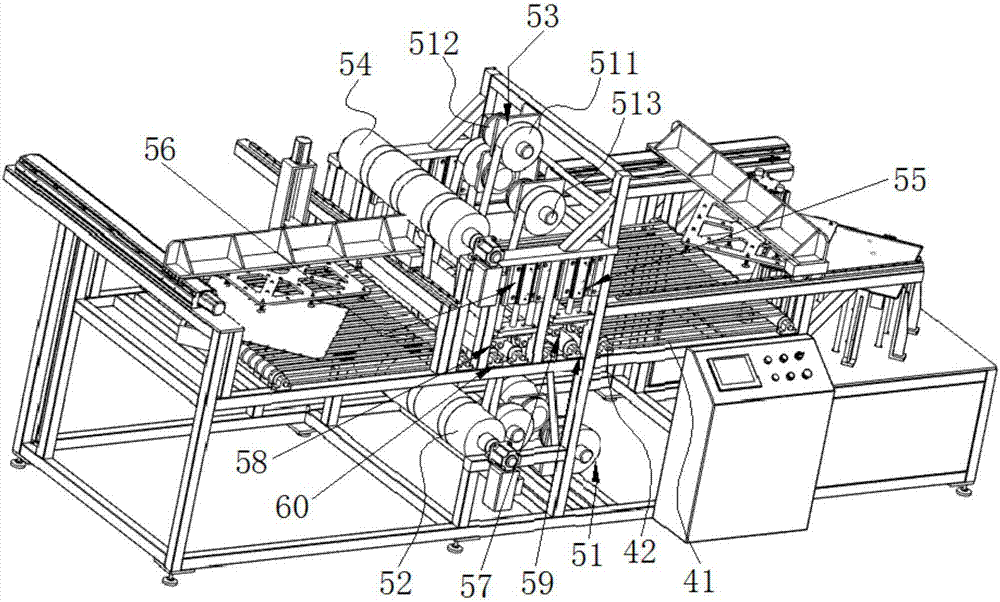

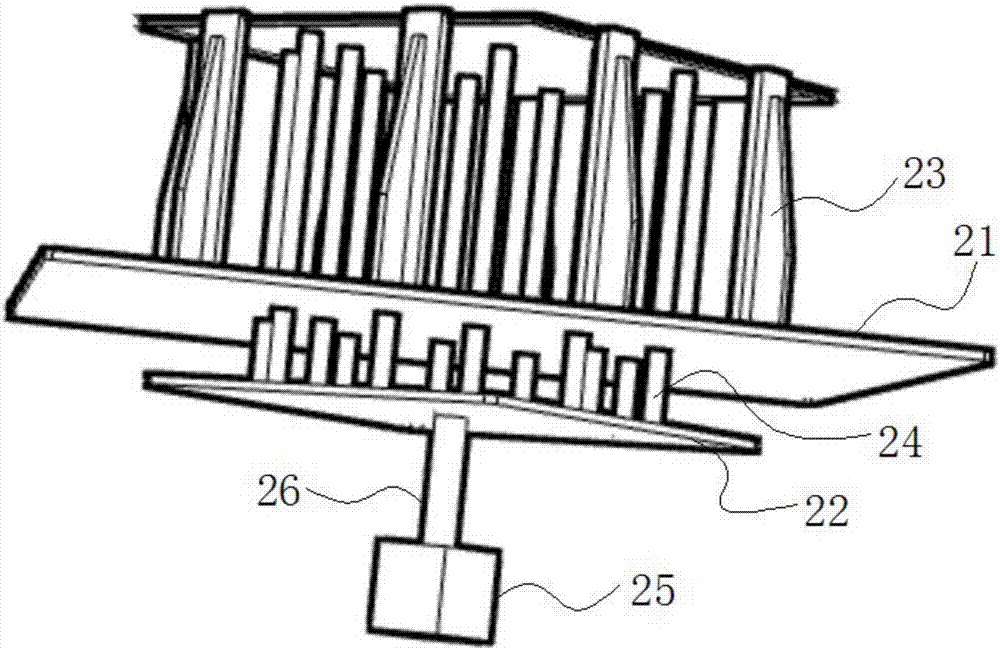

[0038] Described film tearing mechanism 5 comprises a first film tearing mechanism, a second film tearing mechanism, a pressing cylinder, an upper pinch wheel (roller) and a lower pinch wheel (roller), and the first film tearing mechanism includes at least one first A sticky coiled material unwinding mechanism 51 and the first film rewinding wheel 52, the second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com