Glue coating machine with troweling equipment

A technology of gluing machine and equipment, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problem of uneven distribution of glue glue, and achieve the effect of maintaining thickness, wasting resources, and uniform thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

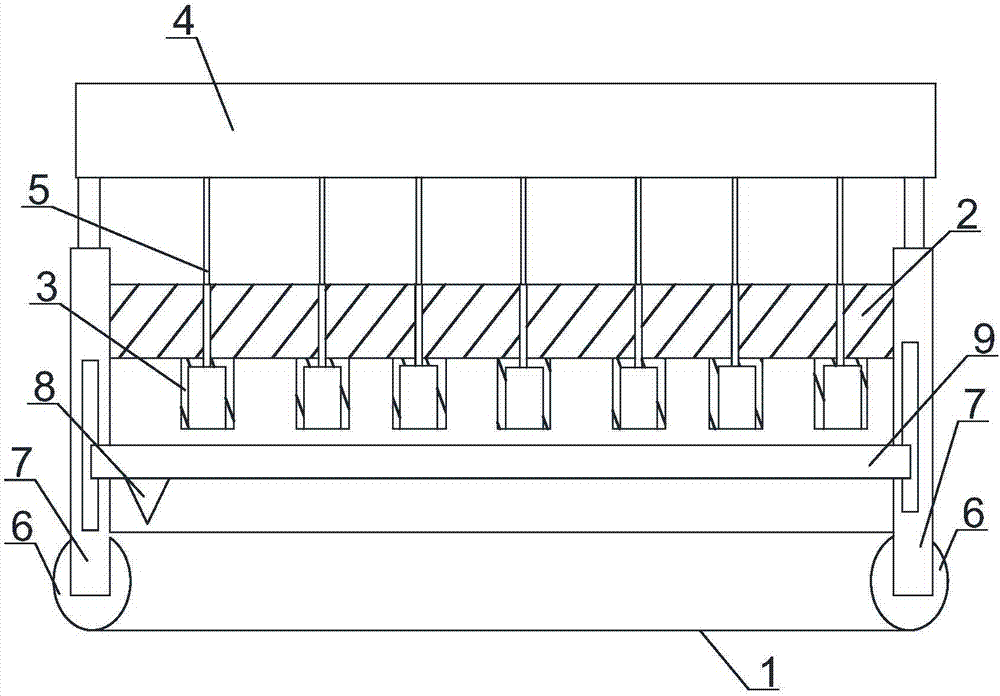

[0020] Such as figure 1 As shown, the present invention has the gluing machine of troweling equipment, comprises the roller conveyer belt 1 that is used for conveying gluing workpiece, and described roller conveyer belt 1 is provided with the fixed plate 2 parallel with roller conveyer belt 1, the fixed plate 2 There are a plurality of cylinders 3 with lower ends open below, and all cylinders 3 are located on the orthographic projection line of the long central axis of the roller conveyor belt 1 on the lower surface of the fixed plate 2, and the cylinders 3 are on the orthographic projection line, etc. distance distribution, the top of the fixed plate 2 is provided with a container 4 of glue-coated glue, and the bottom of the container 4 is provided with a rubber outlet pipe 5 that communicates with the cylindrical tube 3 one by one. On the two rollers 6 of the roller conveyor belt 1 Both are provided with telescopic columns 7 that are fixedly connected to the fixed plate 2, a...

Embodiment 2

[0023] The long side of scraper 8 is a knife edge, and the long side of scraper 8 is parallel with the wide side of roller conveyor belt 1, and the long side length of scraper 8 is equal to the wide side length of roller conveyor belt 1. The scraper 3 is a triangular prism scraper, and the edge of the scraper 3 is an edge of the triangular prism.

[0024] The length of the knife edge of the scraper is equal to the wide side of the roller conveyor belt, which improves the efficiency of scraping the glue by the scraper. The edge width of the triangular prism is extremely thin, and the amount of adhesive glue on the knife edge is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com