Spliced middle partition plate and method for transforming traditional rectifying tower

A middle partition and splicing technology, which is applied in separation methods, chemical instruments and methods, fractionation, etc., can solve problems such as installation difficulties, gas-liquid phase leakage on both sides of the partition, etc., to reduce stress damage, reduce investment, Conducive to the effect of long-term stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

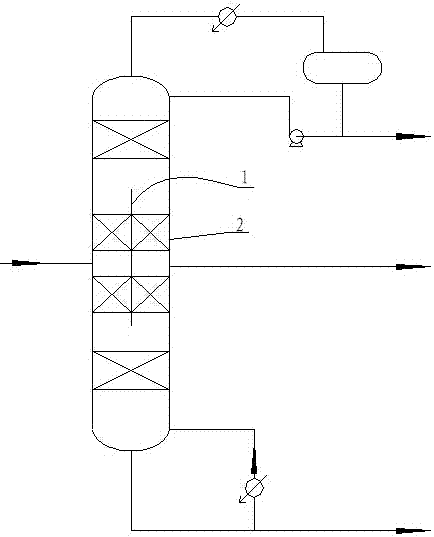

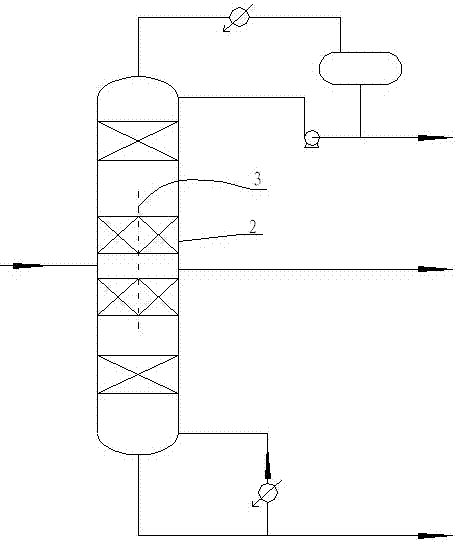

Method used

Image

Examples

Embodiment 1

[0034] Through the calculation of the physical properties of the raw materials, the height of the public rectification section, the height of the partition section and the height of the public stripping section when the old column is transformed into a partition column are determined. Determine the number of manholes in the original tower and the number of manholes in the partition tower, and seal the redundant manholes. If the original tower is a packed tower, clear the internals such as the packing support in the tower; if the original tower is a plate tower, clear the tower internals such as floats, reinforcing rings, and collecting cones in the tower to ensure that the space in the tower is sufficient for the transformation of the clapboard tower .

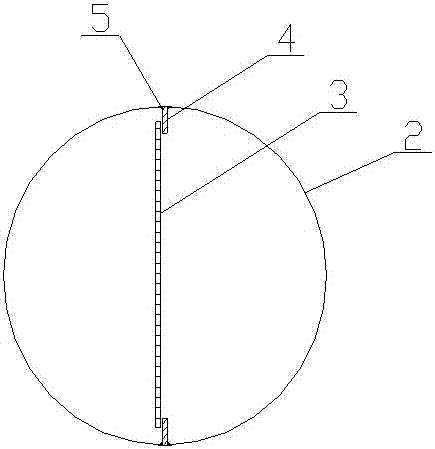

[0035] Determine the installation direction of the partition according to the site conditions of the tower. The fixing surface of the slats and the partition is processed with concave and convex surface (such as Figure 4 )....

Embodiment 2

[0037] Same as Example 1, the difference is that the fixing method between the slats and the partition does not adopt the form of interlocking concave and convex surfaces, but adopts the fixing method of sealing plate + bolt fastening (such as Figure 8 ): The bolt openings of the partition plate 3, the slat 4 and the sealing plate 15 correspond one by one to ensure the smooth installation of the bolts. After installing the sealing plates 15 at both ends of the dividing plate, install the sealing plate 16 between the upper and lower dividing plates. The bolt holes of the sealing plate 16 correspond to the horizontal direction bolt holes of the dividing plate 3 to ensure the smooth installation and sealing of the bolts. The remaining partitions are installed in sequence according to the above method.

[0038] The present invention solves the engineering problem of transforming a conventional rectification tower into a partitioned-wall rectification tower through the special des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com